Section 1

SAFETY

4

J.

Keep personnel out of line with and away from

the discharge opening of hoses, tools or other

points of compressed air discharge.

K. DO NOT

use air at pressures higher than 30

psig (2.1 bar) for cleaning purposes, and then only

with effective chip guarding and personal protec-

tive equipment per OSHA Standard 29 CFR

1910.242 (b) or any applicable Federal, State and

Local codes, standards and regulations.

L. DO NOT

engage in horseplay with air hoses as

death or serious injury may result.

M.

This equipment is supplied with an ASME de-

signed pressure vessel protected by an ASME

rated relief valve. Lift the handle once a week to

make sure the valve is functional.

DO NOT

lift the

handle while machine is under pressure.

N.

If the machine is installed in an enclosed area it is

necessary to vent the relief valve to the outside of

the structure or to an area of non---exposure.

O. DO NOT

remove radiator filler cap until the cool-

ant temperature is below its boiling point. Then

loosen cap slowly to its stop to relieve any excess

pressure and make sure coolant is not boiling be-

fore removing cap completely. Remove radiator

filler cap only when cool enough to touch with a

bare hand.

P.

The ethyl ether in the replaceable cylinders used

in diesel ether starting aid systems (optional) is un-

der pressure.

DO NOT

puncture or incinerate

those cylinders.

DO NOT

attempt to remove the

center valve core or side pressure relief valve from

these cylinders regardless of whether they are full

or empty.

Q.

If a manual blowdown valve is provided on the

receiver, open the valve to insure all internal pres-

sure has been vented prior to servicing any pres-

surized component of the compressor air/fluid sys-

tem.

1.4 FIRE AND EXPLOSION

A.

Refuel at a service station or from a fuel tank de-

signed for its intended purpose. If this is not possi-

ble, ground the compressor to the dispenser prior

to refueling.

B.

Clean up spills of fuel, fluid, battery electrolyte or

coolant immediately if such spills occur.

C.

Shut off air compressor and allow it to cool.

Then keep sparks, flames and other sources of ig-

nition away and

DO NOT

permit smoking in the vi-

cinity when adding fuel, or when checking or add-

ing electrolyte to batteries, or when checking or

adding fluid, or when checking diesel engine ether

starting aid systems or replacing cylinders, or

when refilling air line anti---icer systems antifreeze

compound.

D. DO NOT

permit liquids, including air line anti---

icer system antifreeze compound or fluid film to ac-

cumulate on bottom covers or on, under or around

acoustical material, or on any external or internal

surfaces of the air compressor. Wipe down using

an aqueous industrial cleaner or steam clean as re-

quired. If necessary remove acoustical material,

clean all surfaces and then replace acoustical ma-

terial. Any acoustical material with a protective cov-

ering that has been torn or punctured should be re-

placed immediately to prevent accumulation of liq-

uids or fluid film within the material

. DO NOT

use

flammable solvents for cleaning purposes.

E.

Disconnect the grounded (negative) battery

connection prior to attempting any repairs or clean-

ing inside the enclosure. Tag the battery connec-

tions so others will not unexpectedly reconnect it.

F.

Keep electrical wiring, including the battery ter-

minals and other terminals, in good condition. Re-

place any wiring that has cracked, cut abraded or

otherwise degraded insulation or terminals that are

worn, discolored or corroded. Keep all terminals

clean and tight.

G.

Turn off battery charger before making or break-

ing connections to the battery.

H.

Keep grounded conductive objects such as

tools away from exposed live electrical parts such

as terminals to avoid arcing which might serve as a

source of ignition.

I.

Replace damaged fuel tanks or lines immediately

rather than attempt to weld or otherwise repair

them.

DO NOT

store or attempt to operate the

compressor with any known leaks in the fuel sys-

tem. Tag the compressor and render it inoperative

until repair can be made.

J.

Remove any acoustical material or other material

that may be damaged by heat or that may support

combustion prior to attempting weld repairs. Re-

move diesel engine ether starting aid cylinders and

air line anti---icer system components containing

antifreeze compound, prior to attempting weld re-

pairs in any place other than the fuel system.

DO

NOT

weld on or near the fuel system.

K.

Keep a suitable fully charged class BC or ABC

fire extinguisher or extinguishers nearby when

servicing and operating the compressor.

L.

Keep oily rags, trash, leaves, litter or other com-

bustibles out of and away from the compressor.

M.

Open all access doors and allow the enclosure

to ventilate thoroughly prior to attempting to start

the engine.

N. DO NOT

operate compressor under low over-

hanging leaves or permit such leaves to contact hot

exhaust system surfaces when operating the com-

pressor in forested areas.

O.

Ethyl ether used in diesel engine ether starting

aid systems is extremely flammable. Change cylin-

Summary of Contents for 185H

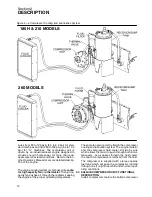

Page 6: ......

Page 14: ...8 NOTES...

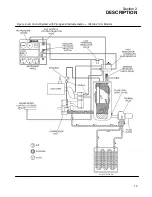

Page 20: ...Section 2 DESCRIPTION 14 Figure 2 4B Control System with Piping and Instrumentation 260 Models...

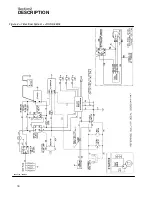

Page 23: ...Section 2 DESCRIPTION 17 Figure 2 6 Instrument Panel Group...

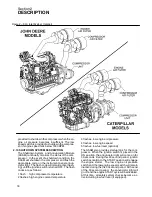

Page 24: ...Section 2 DESCRIPTION 18 Figure 2 7 Electrical System JOHN DEERE 02250144 446R05...

Page 25: ...Section 2 DESCRIPTION 19 Figure 2 7A Electrical System CATERPILLAR P02250144 395R04...

Page 26: ...20 NOTES...

Page 30: ...24 NOTES...

Page 36: ...Section 5 MAINTENANCE 30 Figure 5 4 Control System Adjustment 185H 210 MODELS 260 MODELS...

Page 42: ...36 NOTES...

Page 49: ...Section 7 ILLUSTRATIONS AND PARTS LIST 43 NOTES...

Page 90: ...Section 7 ILLUSTRATIONS AND PARTS LIST 84 7 10 ELECTRICAL PARTS ALL MODELS 02250148 897R00...

Page 128: ...Section 7 ILLUSTRATIONS AND PARTS LIST 122 7 20 DECALS...

Page 130: ...Section 7 ILLUSTRATIONS AND PARTS LIST 124 7 20 DECALS...

Page 132: ...Section 7 ILLUSTRATIONS AND PARTS LIST 126 7 20 DECALS...

Page 134: ...Section 7 ILLUSTRATIONS AND PARTS LIST 128 7 20 DECALS...

Page 136: ...Section 7 ILLUSTRATIONS AND PARTS LIST 130 7 20 DECALS...

Page 138: ...Section 7 ILLUSTRATIONS AND PARTS LIST 132 7 21 DECAL LOCATIONS 02250149 633R01...

Page 142: ......

Page 143: ......