Section 1

SAFETY

5

ders, or maintain or troubleshoot these systems

only in well---ventilated areas away from heat, open

flame or sparks.

DO NOT

install, store or otherwise

expose ether cylinders to temperatures above

160

_

F (71

_

C). Remove ether cylinder from the

compressor when operating in ambient tempera-

tures above 60

_

F (16

_

C).

P. DO NOT

attempt to use ether as a starting aid in

gasoline engines or diesel engines with glow plugs

as serious personnel injury or property damage

may result.

Q. DO NOT

spray ether into compressor air filter or

into an air filter that serves both the engine and the

compressor as serious damage to the compressor

or personal injury may result.

R.

Antifreeze compound used in air line anti---icer

systems contains methanol which is flammable.

Use systems and refill with compound only in well---

ventilated areas away from heat, open flames or

sparks.

DO NOT

expose any part of these systems

or the antifreeze compound to temperatures above

150

_

F (66

_

C). Vapors from the antifreeze com-

pound are heavier than air.

DO NOT

store com-

pound or discharge treated air in confined or un-

ventilated areas.

DO NOT

store containers or anti-

freeze compound in direct sunlight.

S.

Store flammable fluids and materials away from

your work area. Know where fire extinguishers are

and how to use them, and for what type of fire they

are intended. Check readiness of fire suppression

systems and detectors if so equipped.

1.5 MOVING PARTS

A.

Keep hands, arms and other parts of the body

and also clothing away from belts, pulleys and

other moving parts.

B. DO NOT

attempt to operate the compressor

with the fan or other guards removed.

C.

Wear snug---fitting clothing and confine long hair

when working around this compressor, especially

when exposed to hot or moving parts inside the en-

closure.

D.

Keep access doors closed except when making

repairs or adjustments, performing service or when

starting or stopping the compressor.

E.

Make sure all personnel are out of and clear of

the compressor prior to attempting to start or oper-

ate it.

F.

Shut off engine before adding fuel, fluid, coolant

lubricants, air line antifreeze compound or battery

electrolyte, or before replacing ether starting aid

cylinders.

G.

Disconnect the grounded negative battery con-

nection to prevent accidental engine operation

prior to attempting repairs or adjustments. Tag the

battery connection so others will not unexpectedly

reconnect it.

H.

When adjusting the controls, it may require op-

eration of the equipment during adjustment.

DO

NOT

come in contact with any moving parts while

adjusting the control regulator and setting the en-

gine RPM. Make all other adjustments with the en-

gine shut off. When necessary, make adjustment,

other than setting control regulator and engine

RPM, with the engine shut off. If necessary, start the

engine and check adjustment. If adjustment is in-

correct, shut engine off, readjust, then restart the

engine to recheck adjustment.

I.

Keep hands, feet, floors, controls and walking

surfaces clean and free of fluid, water, antifreeze or

other liquids to minimize possibility of slips and

falls.

1.6 HOT SURFACES, SHARP EDGES AND SHARP

CORNERS

A.

Avoid bodily contact with hot fluid, hot coolant,

hot surfaces and sharp edges and corners.

B.

Keep all parts of the body away from all points of

air discharge and away from hot exhaust gases.

C.

Wear personal protective equipment including

gloves and head covering when working in, on or

around the compressor.

D.

Keep a first aid kit handy. Seek medical assis-

tance promptly in case of injury.

DO NOT

ignore

small cuts and burns as they may lead to infection.

1.7 TOXIC AND IRRITATING SUBSTANCES

A. DO NOT

use air from this compressor for respi-

ration (breathing) except in full compliance with

OSHA Standards 29 CFR 1920 and any other Fed-

eral, State or Local codes or regulations.

DANGER

!

Death or serious injury may occur from inhaling

compressed air without using proper safety

equipment. See OSHA standards, and/or any

Federal, State or Local codes or regulations on

safety equipment.

B. DO NOT

use air line anti---icer systems in air

lines supplying respirators or other breathing air

utilization equipment and

DO NOT

discharge air

from these systems into unventilated or other con-

fined areas.

C.

Operate the compressor only in open or well---

ventilated areas.

D.

If the compressor is operated indoors, dis-

charge engine exhaust fumes outdoors.

E.

Locate the compressor so that exhaust fumes

are not apt to be carried towards personnel, air in-

takes servicing personnel areas or towards the air

intake of any portable or stationary compressor.

Summary of Contents for 185H

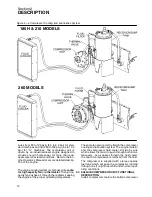

Page 6: ......

Page 14: ...8 NOTES...

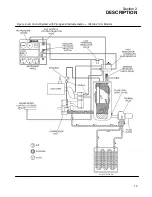

Page 20: ...Section 2 DESCRIPTION 14 Figure 2 4B Control System with Piping and Instrumentation 260 Models...

Page 23: ...Section 2 DESCRIPTION 17 Figure 2 6 Instrument Panel Group...

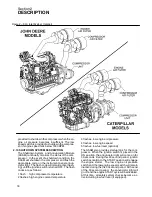

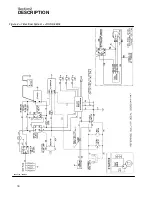

Page 24: ...Section 2 DESCRIPTION 18 Figure 2 7 Electrical System JOHN DEERE 02250144 446R05...

Page 25: ...Section 2 DESCRIPTION 19 Figure 2 7A Electrical System CATERPILLAR P02250144 395R04...

Page 26: ...20 NOTES...

Page 30: ...24 NOTES...

Page 36: ...Section 5 MAINTENANCE 30 Figure 5 4 Control System Adjustment 185H 210 MODELS 260 MODELS...

Page 42: ...36 NOTES...

Page 49: ...Section 7 ILLUSTRATIONS AND PARTS LIST 43 NOTES...

Page 90: ...Section 7 ILLUSTRATIONS AND PARTS LIST 84 7 10 ELECTRICAL PARTS ALL MODELS 02250148 897R00...

Page 128: ...Section 7 ILLUSTRATIONS AND PARTS LIST 122 7 20 DECALS...

Page 130: ...Section 7 ILLUSTRATIONS AND PARTS LIST 124 7 20 DECALS...

Page 132: ...Section 7 ILLUSTRATIONS AND PARTS LIST 126 7 20 DECALS...

Page 134: ...Section 7 ILLUSTRATIONS AND PARTS LIST 128 7 20 DECALS...

Page 136: ...Section 7 ILLUSTRATIONS AND PARTS LIST 130 7 20 DECALS...

Page 138: ...Section 7 ILLUSTRATIONS AND PARTS LIST 132 7 21 DECAL LOCATIONS 02250149 633R01...

Page 142: ......

Page 143: ......