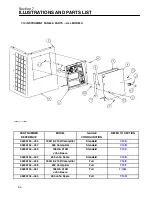

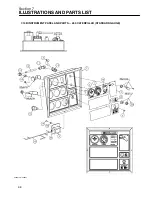

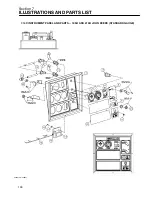

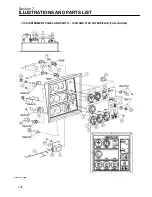

Section 7

ILLUSTRATIONS AND PARTS LIST

105

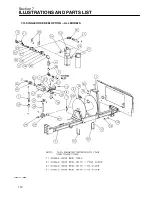

7.14E INSTRUMENT PANEL AND PARTS -- 185H AND 210H CATERPILLAR (FULL GAUGE)

key

part

number

description

number

quantity

1

gauge, pressure air 0---300 2”

02250044---361

1

2

gauge, volt---meter 12 volt 2”

02250044---366

1

3

gauge, pressure mech 0---100psi 2”

02250050---516

1

4

hour---meter, 12---24vdc 10000hr 2”

02250050---517

1

5

tee, m run 3/8”tube x 1/4”npt

02250099---615

2

6

elbow, 90 3/8”tube x 1/4”npt m

02250099---626

2

7

tube, nylon .375”od x .050w black

02250099---630

2 ft

8

gauge, temp mech 48” 140---300$sf

02250102---619

1

9

controller, 185/375 shutdown

module (ssam)

02250126---682

1

10

lense, cliplite led

02250129---189

1

11

panel, instrument plastic ssam

02250129---190

1

12

decal, dual pressure 185---375 ssam

02250130---630

1

13

decal, starting aid 185---375 cat

02250130---631

1

14

harness, voltmeter 125---425 jd/cat

02250130---635

1

15

decal, group full gauge (ssam)

02250131---486

1

16

switch, engine ignition 12---volt

02250132---883

1

17

valve, ball 2---way 1/4”npt

02250136---999

2

18

elbow, 90 f 3/8”tube x 1/4”npt

02250137---033

1

19

cover, access ssam molded abs

02250137---265

1

20

gauge, temp mech 8ft 140---300$sf

02250143---278

1

21

harness, wiring 210h---260 cat t2

02250154---334

1

22

adapter, red 1/2---14 npt murphy thrd

02250155---384

1

23

switch, starter push---button

040038

1

24

screw, tc---f rd hd #6---32 x 1/2

835700---050

2

25

washer, pl---b reg pltd #6

838200---045

2

26

bushing, red pltd 1/4 x 1/8

867100---005

1

PLEASE NOTE: WHEN ORDERING PARTS, INDICATE SERIAL NUMBER OF COMPRESSOR

Summary of Contents for 185H

Page 6: ......

Page 14: ...8 NOTES...

Page 20: ...Section 2 DESCRIPTION 14 Figure 2 4B Control System with Piping and Instrumentation 260 Models...

Page 23: ...Section 2 DESCRIPTION 17 Figure 2 6 Instrument Panel Group...

Page 24: ...Section 2 DESCRIPTION 18 Figure 2 7 Electrical System JOHN DEERE 02250144 446R05...

Page 25: ...Section 2 DESCRIPTION 19 Figure 2 7A Electrical System CATERPILLAR P02250144 395R04...

Page 26: ...20 NOTES...

Page 30: ...24 NOTES...

Page 36: ...Section 5 MAINTENANCE 30 Figure 5 4 Control System Adjustment 185H 210 MODELS 260 MODELS...

Page 42: ...36 NOTES...

Page 49: ...Section 7 ILLUSTRATIONS AND PARTS LIST 43 NOTES...

Page 90: ...Section 7 ILLUSTRATIONS AND PARTS LIST 84 7 10 ELECTRICAL PARTS ALL MODELS 02250148 897R00...

Page 128: ...Section 7 ILLUSTRATIONS AND PARTS LIST 122 7 20 DECALS...

Page 130: ...Section 7 ILLUSTRATIONS AND PARTS LIST 124 7 20 DECALS...

Page 132: ...Section 7 ILLUSTRATIONS AND PARTS LIST 126 7 20 DECALS...

Page 134: ...Section 7 ILLUSTRATIONS AND PARTS LIST 128 7 20 DECALS...

Page 136: ...Section 7 ILLUSTRATIONS AND PARTS LIST 130 7 20 DECALS...

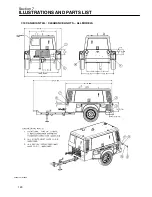

Page 138: ...Section 7 ILLUSTRATIONS AND PARTS LIST 132 7 21 DECAL LOCATIONS 02250149 633R01...

Page 142: ......

Page 143: ......