Section 1

SAFETY

6

F.

Fuels, fluids, coolants, lubricants and battery

electrolyte used in the compressor are typical of the

industry. Care should be taken to avoid accidental

ingestions and/or skin contact. In the event of in-

gestion seek medical treatment promptly.

DO NOT

induce vomiting if fuel is ingested. Wash with soap

and water in the event of skin contact.

G.

Wear an acid---resistant apron and a face shield

or goggles when servicing the battery. If electrolyte

is spilled on skin or clothing, immediately flush with

large quantities of water.

H.

Ethyl ether used in diesel engine ether starting

aid systems is toxic, harmful or fatal if swallowed.

Avoid contact with the skin or eyes and avoid

breathing the fumes. If swallowed,

DO NOT

induce

vomiting, but call a physician immediately.

I.

Wear goggles or a full face shield when testing

ether starting aid systems or when adding anti-

freeze compound to air line anti---icer systems.

Keep openings of valve or atomizer tube of ether

starting aid system pointed away from yourself and

other personnel.

J.

If ethyl ether or air line anti---icer system anti-

freeze compound enters the eyes or if fumes irritate

the eyes, they should be washed with large quanti-

ties of clean water for 15 minutes. A physician,

preferably any eye specialist, should be contacted

immediately.

K. DO NOT

store ether cylinders or air line anti---

icer system antifreeze compound in operator’s

cabs or in other similar confined areas.

L.

The antifreeze compound used in air line anti---

icer systems contains methanol and is toxic, harm-

ful or fatal if swallowed. Avoid contact with the skin

or eyes and avoid breathing the fumes. If swal-

lowed, induce vomiting by administering a table-

spoon of salt in each glass of clean warm water un-

til vomit is clear, then administer two tablespoons of

baking soda in a glass of clean water. Have patient

lay down and cover eyes to exclude light. Call a

physician immediately.

1.8 ELECTRICAL SHOCK

A.

Keep the towing vehicle or equipment carrier,

compressor hoses, tools and all personnel at least

10 feet (3 meters) from power lines and buried ca-

bles.

B.

Keep all parts of the body and any hand---held

tools or other conductive objects away from ex-

posed live parts of electrical system. Maintain dry

footing, stand on insulating surfaces and

DO NOT

contact any other portion of the compressor when

making adjustments or repairs to exposed live

parts of the electrical system.

C.

Attempt repairs only in clean, dry and well---

lighted and ventilated areas.

D.

Stay clear of the compressor during electrical

storms! It can attract lightning.

1.9 LIFTING

A.

If the compressor is provided with a lifting bail,

then lift by the bail provided. If no bail is provided,

then lift by sling. Compressors to be air lifted by

helicopter must not be supported by the lifting bail,

but by slings instead. In any event, lift only in full

compliance with OSHA Standards 29 CFR 1910

subpart N or any other Local, State, Military and

Federal regulations that may apply.

B.

Inspect lifting bail and points of attachment for

cracked welds and for cracked, bent, corroded or

otherwise degraded members and for loose bolts

or nuts prior to lifting.

C.

Make sure entire lifting, rigging and supporting

structure has been inspected, is in good condition

and has a rated capacity of at least the net weight of

the compressor plus an additional 10% allowance

for weight of snow, ice, mud or stored tools and

equipment. If your are unsure of the weight, then

weigh compressor before lifting.

D.

Make sure lifting hook has a functional safety

latch or equivalent, and is fully engaged and

latched on the bail.

E.

Use guide ropes or equivalent to prevent twisting

or swinging of the compressor once it has been

lifted clear of the ground.

F. DO NOT

attempt to lift in high winds.

G.

Keep all personnel out from under and away

from the compressor whenever it is suspended.

H.

Lift compressor no higher than necessary.

I.

Keep lift operator in constant attendance when-

ever compressor is suspended.

J.

Set compressor down only on a level surface ca-

pable of supporting at least its net weight plus an

additional 10% allowance for the weight of snow,

ice, mud or stored tools and equipment.

K.

If the compressor is provided with parking

brakes, make sure they are set, and in any event,

block or chock both sides of all running wheels be-

fore disengaging the lifting hook.

1.10 ENTRAPMENT

A.

Make sure all personnel are out compressor be-

fore closing and latching enclosure doors.

B.

If the compressor is large enough to hold a man

and if it is necessary to enter it to perform service

adjustments, inform other personnel before doing

so, or else secure the access door in the open posi-

tion to avoid the possibility of others closing and

possibly latching the door with personnel inside.

Summary of Contents for 185H

Page 6: ......

Page 14: ...8 NOTES...

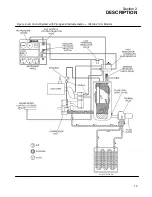

Page 20: ...Section 2 DESCRIPTION 14 Figure 2 4B Control System with Piping and Instrumentation 260 Models...

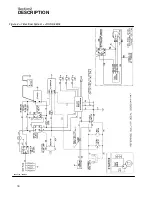

Page 23: ...Section 2 DESCRIPTION 17 Figure 2 6 Instrument Panel Group...

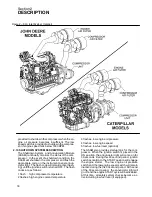

Page 24: ...Section 2 DESCRIPTION 18 Figure 2 7 Electrical System JOHN DEERE 02250144 446R05...

Page 25: ...Section 2 DESCRIPTION 19 Figure 2 7A Electrical System CATERPILLAR P02250144 395R04...

Page 26: ...20 NOTES...

Page 30: ...24 NOTES...

Page 36: ...Section 5 MAINTENANCE 30 Figure 5 4 Control System Adjustment 185H 210 MODELS 260 MODELS...

Page 42: ...36 NOTES...

Page 49: ...Section 7 ILLUSTRATIONS AND PARTS LIST 43 NOTES...

Page 90: ...Section 7 ILLUSTRATIONS AND PARTS LIST 84 7 10 ELECTRICAL PARTS ALL MODELS 02250148 897R00...

Page 128: ...Section 7 ILLUSTRATIONS AND PARTS LIST 122 7 20 DECALS...

Page 130: ...Section 7 ILLUSTRATIONS AND PARTS LIST 124 7 20 DECALS...

Page 132: ...Section 7 ILLUSTRATIONS AND PARTS LIST 126 7 20 DECALS...

Page 134: ...Section 7 ILLUSTRATIONS AND PARTS LIST 128 7 20 DECALS...

Page 136: ...Section 7 ILLUSTRATIONS AND PARTS LIST 130 7 20 DECALS...

Page 138: ...Section 7 ILLUSTRATIONS AND PARTS LIST 132 7 21 DECAL LOCATIONS 02250149 633R01...

Page 142: ......

Page 143: ......