Section 4

OPERATION

25

4.1 GENERAL

While Sullair has built into this compressor a compre-

hensive array of controls and indicators to assure

you that it is operating properly, you will want to rec-

ognize and interpret the reading which will call for

service or indicate the beginning of a malfunction.

Before starting your Sullair compressor, read this

section thoroughly and familiarize yourself with the

controls and indicators --- their purpose, location and

use.

4.2 PURPOSE OF CONTROLS

CONTROL OR INDICATOR

PURPOSE

ENGINE SWITCH

Press this switch to the “ ON” (ignition) position to energize

the electrical system of the compressor. Press the switch to

the “START” position to momentarily engage the starter

and start the compressor. Pressthe switch to the “OFF”

position to shut the compressor down. This switch is lo-

cated on the instrument panel.

COLD WEATHER STARTING AID BUTTON

Push this button, prior to compressor start---up, to allow the

engine to warm---up for easy starting.

AIR PRESSURE GAUGE

Continually monitors the pressure inside the receiver sump

at various load and unload conditions.

HOURMETER

Indicates the accumulated hours of operation. Useful for

planning and logging service schedules.

FLUID LEVEL SIGHT GLASS

Monitors the fluid level in the sump. Proper level is visible

halfway up the sight glass. Check the level when the com-

pressor is shut down and on level ground.

COMPRESSOR DISCHARGE TEMPERATURE

Opens the electrical circuit to shut down the compres---

SWITCH

sor when the discharge temperature reaches a specific

value (see Section 3, Specifications).

THERMAL VALVE

Functions as a temperature regulator directing the com-

pressor fluid either to the cooler or to the compressor unit.

MINIMUM PRESSURE DEVICE

Maintains the minimum of 85 psig (5.9 bar) in the compres-

sor sump.

PRESSURE RELIEF VALVE

Opens sump pressure to the atmosphere should pressure

inside the sump exceed 200 psig (13.8 bar) .

AIR INLET VALVE

Regulates the amount of air allowed to enter the air inlet

valve. This regulation is determined by a pressure signal

from the pressure regulator.

PRESSURE REGULATOR (S)

Allows a pressure signal to reach the engine speed control

cylinder and the air inlet valve to control air delivery accord-

ing to demand.

SHUTDOWN SYSTEM/ANNUNCIATOR MODULE (SSAM) Monitors the compressor safety system for shut-

down conditions. The annunciator module on the instru-

ment panel will flash a code indicating the reason for com-

pressor shutdown.

Summary of Contents for 185H

Page 6: ......

Page 14: ...8 NOTES...

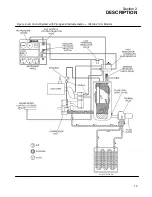

Page 20: ...Section 2 DESCRIPTION 14 Figure 2 4B Control System with Piping and Instrumentation 260 Models...

Page 23: ...Section 2 DESCRIPTION 17 Figure 2 6 Instrument Panel Group...

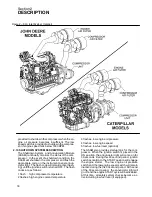

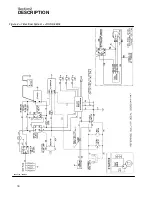

Page 24: ...Section 2 DESCRIPTION 18 Figure 2 7 Electrical System JOHN DEERE 02250144 446R05...

Page 25: ...Section 2 DESCRIPTION 19 Figure 2 7A Electrical System CATERPILLAR P02250144 395R04...

Page 26: ...20 NOTES...

Page 30: ...24 NOTES...

Page 36: ...Section 5 MAINTENANCE 30 Figure 5 4 Control System Adjustment 185H 210 MODELS 260 MODELS...

Page 42: ...36 NOTES...

Page 49: ...Section 7 ILLUSTRATIONS AND PARTS LIST 43 NOTES...

Page 90: ...Section 7 ILLUSTRATIONS AND PARTS LIST 84 7 10 ELECTRICAL PARTS ALL MODELS 02250148 897R00...

Page 128: ...Section 7 ILLUSTRATIONS AND PARTS LIST 122 7 20 DECALS...

Page 130: ...Section 7 ILLUSTRATIONS AND PARTS LIST 124 7 20 DECALS...

Page 132: ...Section 7 ILLUSTRATIONS AND PARTS LIST 126 7 20 DECALS...

Page 134: ...Section 7 ILLUSTRATIONS AND PARTS LIST 128 7 20 DECALS...

Page 136: ...Section 7 ILLUSTRATIONS AND PARTS LIST 130 7 20 DECALS...

Page 138: ...Section 7 ILLUSTRATIONS AND PARTS LIST 132 7 21 DECAL LOCATIONS 02250149 633R01...

Page 142: ......

Page 143: ......