Section 5

MAINTENANCE

32

concerning the trouble should be systematically

analyzed before undertaking any repairs or compo-

nent replacement procedures.

A detailed visual inspection is worth performing for

almost all problems. Doing so may prevent unnec-

essary additional damage to the compressor.

Always remember to:

1. Check for loose wiring.

2. Check for damaged piping.

3. Check for parts damaged by heat or an electrical

short circuit, usually apparent by discoloration or

a burnt odor.

Should the problem(s) persist after making the rec-

ommended check, consult your nearest Sullair rep-

resentative or the Sullair Corporation.

5.9 TROUBLESHOOTING GUIDE

SYMPTOM

PROBABLE CAUSE

REMEDY

ENGINE DOES NOT CRANK OR CRANKS ONLY WITHOUT STARTING:

NO FLASH CODE:

Low Voltage or Battery disconnected

Check battery cables and tighten if necessary.

Check ground wire for proper attachment to frame.

Tighten as required.

Low Voltage or Battery disconnected

Recharge or replace battery if required.

Blown fuse in wiring harness

Remove and inspect fuse. Replace if necessary.

Instrument panel connectors loose or

Checked instrument panel connectors and

disconnected

reattach if required.

Check instrument panel wires for broken

connections or corrosion. Clean and/or replace if

required

Faulty SSAM module

Replace the SSAM Module.

FLASH CODE: ONE FLASH

Compressor temperature switch is open

Check wiring connection to switch and tighten as

required.

Check switch continuity to ground and replace if

necessary.

If the compressor feels hot --- see symptom

“COMPRESSOR OVERHEATING”.

FLASH CODE: TWO FLASHES

Engine coolant temperature switch is open

Check wiring connection to switch and tighten as

required.

Check switch continuity to ground and replace if

necessary.

If the compressor feels hot --- see symptom

“ENGINE OVERHEATING”.

FLASH CODE: FOUR FLASHES

Did not attempt to start compressor within

When starting the compressor, immediately

30 seconds of turning ignition switch ON.

turn the Ignition Switch to the START position

and begin the engine cycle.

Low Battery Voltage

Loose battery cables and tighten if necesssary.

Recharge or replace battery if necessary.

No fuel

Check fuel level and fuel if necessary.

Water/dirt in fuel and/or fuel filter

Drain water from fuel water separators on fuel

filters. Siphon water from fuel tank and clean

fuel tank if necessary.

Plugged fuel filter

Replace fuel filter if necessary.

Summary of Contents for 185H

Page 6: ......

Page 14: ...8 NOTES...

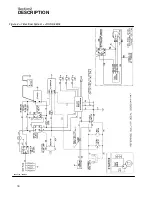

Page 20: ...Section 2 DESCRIPTION 14 Figure 2 4B Control System with Piping and Instrumentation 260 Models...

Page 23: ...Section 2 DESCRIPTION 17 Figure 2 6 Instrument Panel Group...

Page 24: ...Section 2 DESCRIPTION 18 Figure 2 7 Electrical System JOHN DEERE 02250144 446R05...

Page 25: ...Section 2 DESCRIPTION 19 Figure 2 7A Electrical System CATERPILLAR P02250144 395R04...

Page 26: ...20 NOTES...

Page 30: ...24 NOTES...

Page 36: ...Section 5 MAINTENANCE 30 Figure 5 4 Control System Adjustment 185H 210 MODELS 260 MODELS...

Page 42: ...36 NOTES...

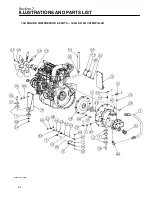

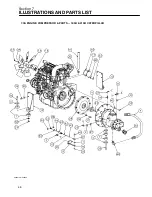

Page 49: ...Section 7 ILLUSTRATIONS AND PARTS LIST 43 NOTES...

Page 90: ...Section 7 ILLUSTRATIONS AND PARTS LIST 84 7 10 ELECTRICAL PARTS ALL MODELS 02250148 897R00...

Page 128: ...Section 7 ILLUSTRATIONS AND PARTS LIST 122 7 20 DECALS...

Page 130: ...Section 7 ILLUSTRATIONS AND PARTS LIST 124 7 20 DECALS...

Page 132: ...Section 7 ILLUSTRATIONS AND PARTS LIST 126 7 20 DECALS...

Page 134: ...Section 7 ILLUSTRATIONS AND PARTS LIST 128 7 20 DECALS...

Page 136: ...Section 7 ILLUSTRATIONS AND PARTS LIST 130 7 20 DECALS...

Page 138: ...Section 7 ILLUSTRATIONS AND PARTS LIST 132 7 21 DECAL LOCATIONS 02250149 633R01...

Page 142: ......

Page 143: ......