Section 6

MAINTENANCE

25

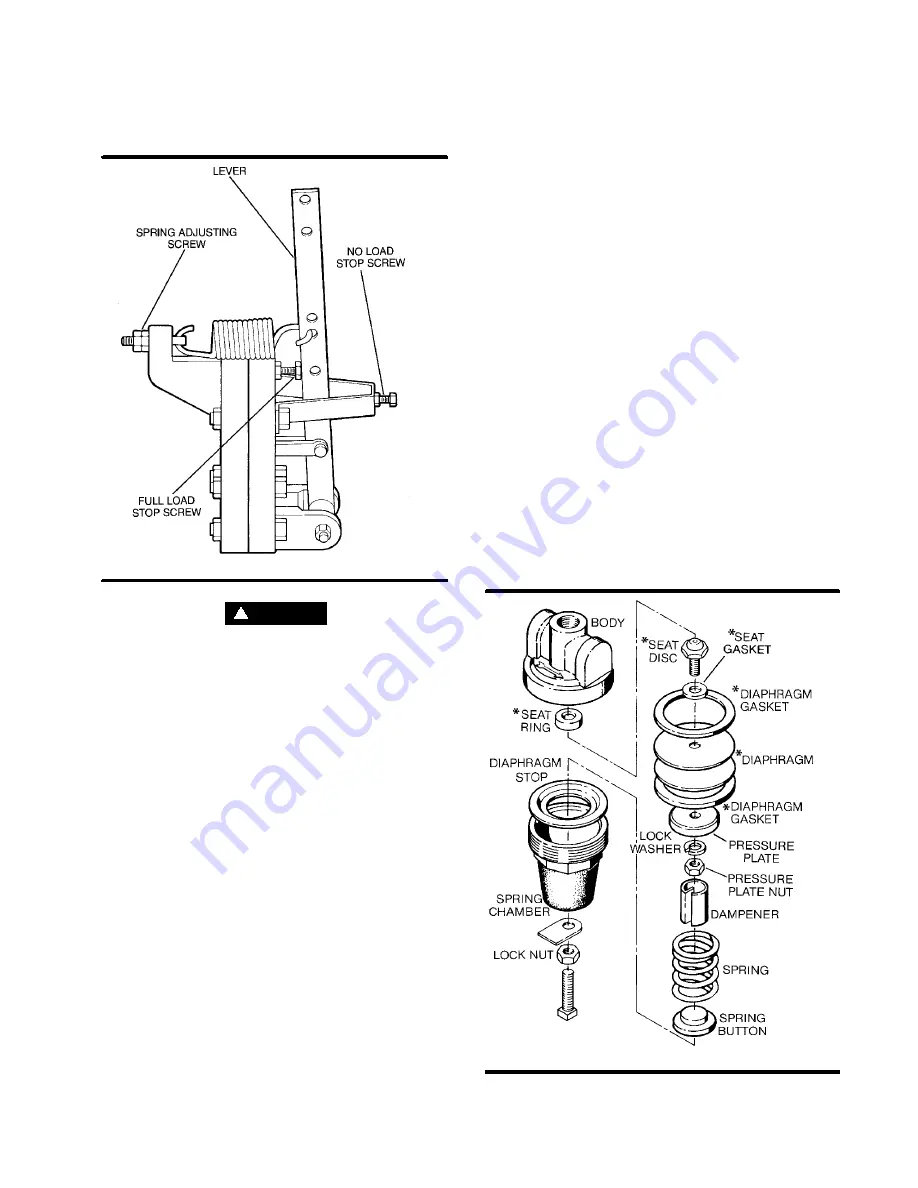

* Repair Kit P/N 250020-353

Figure 6-6 Sullicon Control (P/N 011682-003)

WARNING

!

DO NOT touch the electrical contacts of the pres-

sure switch with any metallic object. Severe elec-

trical shocks may occur. Cycle the Control System

several times and recheck all the pressure set-

tings.

PRESSURE REGULATOR VALVE MAINTE-

NANCE

Ref er t o F igur e

. P r es s ur e r egulat or v alv e ( P / N

048059) maintenance normally requires the replace-

ment of the internal diaphragm. Use repair kit No.

048409 and follow the procedure below for proper

installation

1. Loosen the locknut and turn the adjusting screw

counterclockwise until the inner spring tension is

relieved. The adjusting screw should turn freely

when the spring tension is relieved.

2. Remove the spring chamber from the body to al-

low access to internal parts.

3. Next, remove the spring button and the spring.

The dampener will stay inside the spring as it is re-

moved. Leave the dampener inside the spring as

there is no need to remove it.

4. After removing the spring, remove the diaphragm

stop.

5. At this time, remove the pressure plate nut and

disassemble the pressure plate, diaphragm, dia-

phragm gasket (rubberized asbestos), seat disc

and seat gasket.

6. Remove and discard the seat ring.

7. The next step is to reassemble the regulator using

the new parts provided in the repair kit.

8. Reassemble the diaphragm, pressure plate, dia-

phragm gasket, seat disc and seat disc gasket

and tighten the nut. All of the these parts with the

exception of pressure plate are provided in the re-

pair kit.

9. Replace the seat ring with the new seat ring pro-

vided.

10. Replace the existing diaphragm stop.

11. Next, place these parts in their proper place on the

body and replace the spring as it was prior to dis-

assembly.

12. Place the spring button over the spring as shown.

13. With all parts in order, replace the spring chamber

and tighten.

14. Tighten the adjusting screw until tension is real-

ized.

15. At this time, refer to Control System Adjustment

Procedure to readjust the control regulator.

CONTROL PRESSURE REGULATOR VALVE

M aint enanc e f or t he c ont r ol

pressure regulator valve (P/N 048354) normally re-

quires the replacement of the internal diaphragm.

Use repair kit no. 048410, and follow the procedure

below for proper installation.

* Repair Kit P/N 048409

Figure 6-7 Pressure Regulator Valve

(P/N 048059)

Summary of Contents for 20/12 500 CFM

Page 12: ...Section 2 DESCRIPTION 8 Figure 2 3 Piping and Instrumentation...

Page 14: ...Section 2 DESCRIPTION 10 Figure 2 5 Capacity Control System Typical...

Page 18: ...14 NOTES...

Page 20: ...16 NOTES...

Page 24: ...20 NOTES...

Page 38: ...34 NOTES...

Page 40: ...Section 7 ILLUSTRATIONS AND PARTS LIST 36 7 3 MOTOR FRAME COMPRESSOR AND PARTS...

Page 42: ...Section 7 ILLUSTRATIONS AND PARTS LIST 38 7 4 AIR INLET SYSTEM...

Page 44: ...Section 7 ILLUSTRATIONS AND PARTS LIST 40 7 5 COOLING AND LUBRICATION SYSTEM...

Page 46: ...Section 7 ILLUSTRATIONS AND PARTS LIST 42 7 6 COOLER ASSEMBLY...

Page 48: ...Section 7 ILLUSTRATIONS AND PARTS LIST 44 7 7 DISCHARGE SYSTEM...

Page 50: ...Section 7 ILLUSTRATIONS AND PARTS LIST 46 7 7 DISCHARGE SYSTEM...

Page 52: ...Section 7 ILLUSTRATIONS AND PARTS LIST 48 7 8 INSTRUMENT PANEL AND PARTS...

Page 54: ...Section 7 ILLUSTRATIONS AND PARTS LIST 50 7 9 CONTROL SYSTEM...

Page 56: ...Section 7 ILLUSTRATIONS AND PARTS LIST 52 7 9 CONTROL SYSTEM...

Page 58: ...Section 7 ILLUSTRATIONS AND PARTS LIST 54 7 10 ELECTRIC CONTROL BOX...

Page 60: ...Section 7 ILLUSTRATIONS AND PARTS LIST 56 7 11 UNIT TUBING...

Page 62: ...Section 7 ILLUSTRATIONS AND PARTS LIST 58 7 11 UNIT TUBING...

Page 64: ...Section 7 ILLUSTRATIONS AND PARTS LIST 60 7 12 DECAL GROUP...