Section 6

MAINTENANCE

30

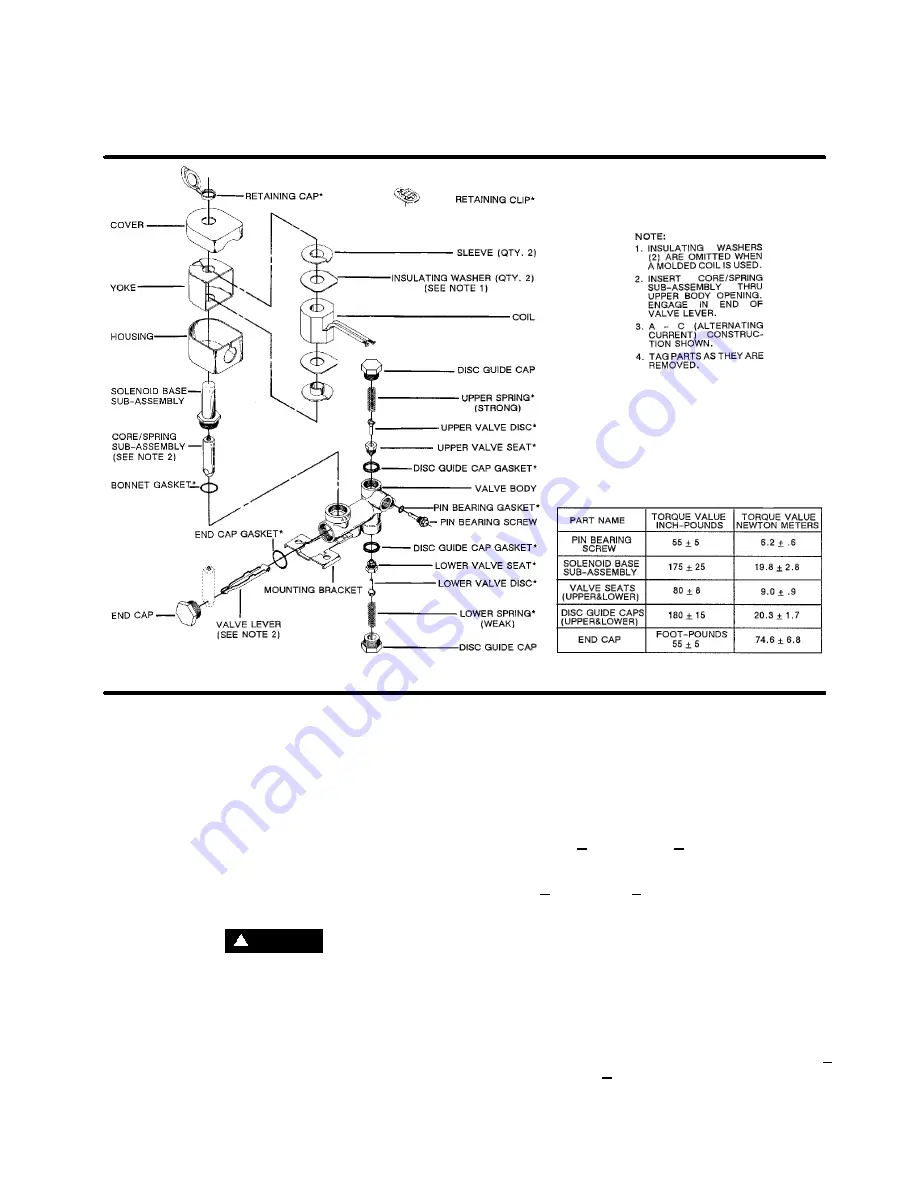

* Repair Kit P/N 042246

Figure 6-13 Pilot Valve (P/N 407390)

5. Remove end cap, end cap gasket and slip core/

spring assembly (A--C Construction) or core (D--C

Construction) off the end of the valve lever and lift

it out through solenoid base sub--assembly open-

ing.

6. Inspect upper and lower valve seats but

DO NOT

remove from valve body unless installing a com-

plete Spare Parts Kit.

7. Clean all parts thoroughly and replace worn or

damaged parts with a complete Spare Parts kit. If

a Spare Parts kit is required, refer to the section

on Installation of New Spare Parts Kit for com-

plete rebuild.

CAUTION

!

Install all new parts. DO NOT retain any old parts

when rebuilding valve. If only partial installation is

made,valve malfunction may occur.

VALVE ASSEMBLY

1. Reassemble in reverse order of disassembly pay-

ing careful attention to exploded view provided for

identification and placement of parts.

2. Lubricate all gaskets with Dow Corning’s Valve

Seal silicone lubricant or equivalent high grade sil-

icone grease.

3. Replace

core/spring

sub--assembly

(A--C

Construction or core (D--C Construction) through

solenoid base sub--assembly opening and en-

gage with lever.

4. Install end cap gasket and end cap. Torque end

cap to 55 + 5 ft./lbs. (75 + 7Nm).

5. Replace bonnet gasket and solenoid base sub--

assembly. Torque solenoid base sub--assembly to

175 + in./lbs. (20 + 3 Nm).

6. Replace solenoid enclosure and retaining cap or

clip.

7. Install valve discs. If lapping is required, refer to

the Lapping Seats and Discs section.

8. For stroke setting requirements (adjustment of

valve discs), refer to the New Seat and Disc Instal-

lation paragraphs of New Spare Parts Kit Section.

9. Install upper and lower springs. Refer to the New

Spring Installation section.

10. Replace disc guide cap gaskets and disc guide

caps (both ends). Torque disc guide caps to 180 +

15 in./lbs (20 + 2 Nm).

Summary of Contents for 20/12 500 CFM

Page 12: ...Section 2 DESCRIPTION 8 Figure 2 3 Piping and Instrumentation...

Page 14: ...Section 2 DESCRIPTION 10 Figure 2 5 Capacity Control System Typical...

Page 18: ...14 NOTES...

Page 20: ...16 NOTES...

Page 24: ...20 NOTES...

Page 38: ...34 NOTES...

Page 40: ...Section 7 ILLUSTRATIONS AND PARTS LIST 36 7 3 MOTOR FRAME COMPRESSOR AND PARTS...

Page 42: ...Section 7 ILLUSTRATIONS AND PARTS LIST 38 7 4 AIR INLET SYSTEM...

Page 44: ...Section 7 ILLUSTRATIONS AND PARTS LIST 40 7 5 COOLING AND LUBRICATION SYSTEM...

Page 46: ...Section 7 ILLUSTRATIONS AND PARTS LIST 42 7 6 COOLER ASSEMBLY...

Page 48: ...Section 7 ILLUSTRATIONS AND PARTS LIST 44 7 7 DISCHARGE SYSTEM...

Page 50: ...Section 7 ILLUSTRATIONS AND PARTS LIST 46 7 7 DISCHARGE SYSTEM...

Page 52: ...Section 7 ILLUSTRATIONS AND PARTS LIST 48 7 8 INSTRUMENT PANEL AND PARTS...

Page 54: ...Section 7 ILLUSTRATIONS AND PARTS LIST 50 7 9 CONTROL SYSTEM...

Page 56: ...Section 7 ILLUSTRATIONS AND PARTS LIST 52 7 9 CONTROL SYSTEM...

Page 58: ...Section 7 ILLUSTRATIONS AND PARTS LIST 54 7 10 ELECTRIC CONTROL BOX...

Page 60: ...Section 7 ILLUSTRATIONS AND PARTS LIST 56 7 11 UNIT TUBING...

Page 62: ...Section 7 ILLUSTRATIONS AND PARTS LIST 58 7 11 UNIT TUBING...

Page 64: ...Section 7 ILLUSTRATIONS AND PARTS LIST 60 7 12 DECAL GROUP...