Section 2

11

EES USER MANUAL

DESCRIPTION

2.1

INTRODUCTION

The Sullair Integral Heat Recovery System is a

means of recovering energy which is expended while

producing compressed air. This energy can be

converted into a useable source of heat. The heat is

stored in the compressor cooling air as it passes over

the compressor motor, fluid cooler and aftercooler.

Latent heat rejected when moisture is condensed

from the compressed air in the aftercooler may also

be recovered. The compressor cooling air may then

be used as preheated makeup air or heating air.

Heat may also be rejected when not required.

Because the heat recovery system is built into the

compressor package it requires a minimal amount of

installation labor. The system has been designed so

that use of auxiliary blowers is not needed as long as

good duct design is practiced.

2.2

APPLICATION

CONSIDERATIONS

G

ENERAL

The Sullair EES is designed primarily to recover the

heat of compression in the form of heated makeup

air. Maximum energy utilization, minimum cost of

installation, and maximum return on investment will

be realized by using the EES in this manner. For

every cubic foot of outside air brought into a building

by the EES, another cubic foot of air that would have

infiltrated into the building at outside temperature will

be eliminated. The fuel savings result from the

primary heating system of the facility

not

having to

heat that cubic foot of air at outside temperature to

the temperature of the heated space.

It is possible for the EES system to operate efficiently

as a heating system; that is, where air is drawn and

heated to some higher temperature (say 90°F

[32°C]), then distributed throughout the heated

space. This usually requires greater capital

investment in the form of a larger ductwork system to

distribute the heated air.

As a preheated makeup air system, air is brought in

from the outside at some low temperature (say 40°F

[14°C]), heated approximately to the heated space

temperature (say 65°F [18°C]), and then released to

the heated space at one location. Since the air is

close to heated space temperature, there is little

advantage in distributing this air throughout the plant.

In either case, the same amount of energy is

recovered, but in the makeup air system, significant

reductions in the installed costs are possible.

It is also possible to utilize the waste heat of

compression for process heating applications such

as drying parts. This type of application will usually

net a greater return on investment because the heat

can be used year round.

DANGER

Any makeup air introduced into a heating or

ventilation system by this system must be

of breathing air quality as defined by appli-

cable codes, laws or regulations.

Summary of Contents for 3000 EES

Page 10: ...NOTES 10 ...

Page 16: ...16 BLANK PAGE ...

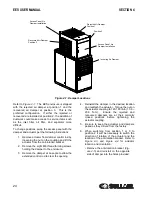

Page 20: ...EES USER MANUAL SECTION 3 20 Figure 3 1 Identification EES 02250175 281 R00 ...

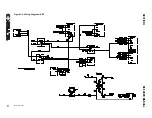

Page 21: ...SECTION 3 EES USER MANUAL 21 Figure 3 2 Wiring Diagram EES 02250175 264 R01 ...

Page 22: ...22 BLANK PAGE ...

Page 28: ...28 BLANK PAGE ...

Page 36: ...36 BLANK PAGE ...

Page 38: ...38 BLANK PAGE ...

Page 44: ...44 BLANK PAGE ...

Page 45: ...Section 8 45 EES USER MANUAL PARTS LISTS ...

Page 46: ...EES USER MANUAL SECTION 8 46 8 1 EES ENCLOSURE ASSEMBLY 02250175 279 R00 ...

Page 48: ...EES USER MANUAL SECTION 8 48 8 2 EES ELECTRICAL CONTROL ASSEMBLY 02250171 648 R00 ...

Page 50: ...EES USER MANUAL SECTION 8 50 8 3 EES DISCHARGE ENCLOSURE ASSEMBLY 02250171 646 R00 ...

Page 52: ...EES USER MANUAL SECTION 8 52 8 4 EES PACKAGE CLEAN AIR INLET OPTION 02250176 044 R00 ...

Page 54: ...54 BLANK PAGE ...

Page 55: ...NOTES 55 ...