300HH, 375, 375H, 375HH, 425 AND 425H USER MANUAL R00

SECTION 2

28

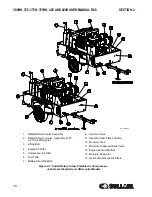

1. Engine Air Filter

2. Compressor Air Filter

3. Air Inlet Valve

4. Compressor

5. Engine

Figure 2-8: Air Inlet System—John Deere

N

ORMAL

O

PERATION

– 80

TO

100

PSIG

(5.6

TO

6.9

BAR

)

OR

80

TO

150

PSIG

(5.6

TO

10.3

BAR

)

FOR

H

MACHINES

OR

80

TO

200

PSIG

(5.6

TO

13.8

BAR

)

FOR

HH

MACHINES

When the warm-up control selector valve handle is

moved to the RUN position, the sump pressure rises

above 80 psig (5.6 bar). At this time, the inlet valve

remains fully open for maximum air output. The

engine will continue to run at full speed during this

phase of operation.

M

ODULATION

– 100

TO

110

PSIG

(6.9

TO

7.5

BAR

)

OR

150

TO

165

PSIG

(10.3

TO

11.4

BAR

)

FOR

H

MACHINES

OR

200

TO

220

PSIG

(13.8

TO

15.2

BAR

)

FOR

HH

MACHINES

If the demand on the compressor is less than its

rated capacity, the service line pressure will rise

above 100 psig (6.9 bar) - low or single pressure

rating: 150 psig (10.3 bar) for “H” rating or 200 psig

(13.8 bar) for “HH” dual or high pressure rating. The

pressure regulating valve gradually opens, applying

pressure to the inlet valve piston and pressure

transducer. This causes the inlet valve to partially

close and reduces the engine speed. As the pressure

increases, the inlet valve piston will further close the

inlet valve and the engine speed will decrease until it

reaches its preset idle speed. When the demand on

the compressor increases, the sump pressure falls

below 110 psig (7.6 bar) or 165 psig (11.4 bar) for “H”

machines, or 220 psig (15.2 bar) for “HH” ones. The

pressure regulating valve closes, the air inlet valve

opens fully, and the engine speed increases to its

preset full load rating.

Between the pressure regulating valve and the inlet

valve, there is a small orifice that vents a small

amount of air into the atmosphere when the pressure

regulating valve is open. This allows changes in air

output to conform to air demand. This orifice also

discharges any accumulated moisture from the

regulator.Shutdown

The blowdown valve is normally closed. At shutdown

the back pressure in the compressor inlet signals the

blowdown valve to vent the sump pressure into the

atmosphere.

2.7

AIR INLET SYSTEM,

FUNCTIONAL DESCRIPTION

. The air inlet system consists of

two air filters, a compressor air inlet valve and

interconnecting piping to the engine and the

compressor.

The air filters are three-stage dry element type filters

that are capable of cleaning extremely dirty air.

However, when operating in dirty environments, the

filters should be checked more frequently.

See

on page 64 for Air Filter

Maintenance Procedures.

2.8

INSTRUMENT PANEL

GROUP, FUNCTIONAL

DESCRIPTION

. The instrument panel group

consists of a molded panel containing an: air

pressure gauge, compressor temperature gauge,

ignition/start switch, PowerView, annunciator light,

idle warm-up control, engine shutdown light, engine

warning light, and a wait to start light. A high-low

pressure selector valve is located on the panel for

“H” and “HH” compressors.

1

2

3

4

5

SU_0000668

Summary of Contents for 300HH

Page 17: ...SECTION 1 15 Safety Symbols 2 ...

Page 18: ...SECTION 1 16 Safety Symbols 3 ...

Page 49: ...SECTION 2 300HH 375 375H 375HH 425 AND 425H USER MANUAL R00 47 2 9 WIRING DIAGRAM ...

Page 60: ...NOTES 58 ...

Page 79: ...NOTES ...