300HH, 375, 375H, 375HH, 425 AND 425H USER MANUAL R00

SECTION 2

30

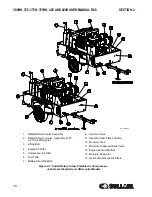

Refer to

for the locations of the following

indicators and controls:

1. The compressor discharge temperature

gauge monitors the temperature of the air/

oil mixture in the sump.

2. The air pressure gauge continuously moni-

tors the sump pressure under various load

conditions.

3. The engine switch energizes the system

and starts the compressor. The engine

switch is pressed to the ON position to ener-

gize the electrical system, and pressed

momentarily to the START position to

engage the starter and start the compres-

sor.

4. The idle warm-up control is turned from

START to RUN after sufficient warm-up is

achieved for full compressor operation.

5. The pressure selector valve on “H” com-

pressors allows the selection of the com-

pressor operating pressure range, 80 to 110

psig (5.6 to 7.6 bar) or 80 to 165 psig (5.6 to

11.4 bar) for “H” models, or 80 to 220 psig

(5.6 to 15.2 bar) for “HH” models.

6. The shutdown indicator light indicates

engine and compressor safety shutdown

status.

7. The engine warning lamp indicates when an

abnormal condition exists. It is not neces-

sary to shutdown the engine immediately,

but the problem should be corrected as

soon as possible.

8. The engine wait to start lamp is illuminated

when conditions are not right for starting.

9. The engine stop lamp signals when the

engine should be stopped immediately or as

soon as possible to prevent engine dam-

age. Correct the problem before restarting.

10. The fuel level gauge indicates the fluid level

in the fuel tank.

11. The PowerView® is a multifunction tool that

allows operators to view a wide range of

engine parameters and engine service

codes.

Summary of Contents for 300HH

Page 17: ...SECTION 1 15 Safety Symbols 2 ...

Page 18: ...SECTION 1 16 Safety Symbols 3 ...

Page 49: ...SECTION 2 300HH 375 375H 375HH 425 AND 425H USER MANUAL R00 47 2 9 WIRING DIAGRAM ...

Page 60: ...NOTES 58 ...

Page 79: ...NOTES ...