300HH, 375, 375H, 375HH, 425 AND 425H USER MANUAL R00

SECTION 5

62

• Meets or exceeds performance require-

ments of current industry standards which

include: ASTM D 6210, John Deere H24A2

and H24C2.

If you are not sure of the coolant that is installed

originally or want to change to a different type, the

cooling system must be cleaned with a commercial

cleaning agent (such as CAT Cooling System

Cleaner p/n 4C-4611) and then completely flushed

and filled with water (preferably distilled) several

times to remove all traces of cleaner and old coolant.

Finally, fill the system with the recommended coolant

using only one brand/type. Cross contamination,

which is caused by adding different types of engine

coolants, may result in the depletion or dropout of

coolant additives; thus leaving cooling system

surfaces unprotected against corrosion.

Corrosion to radiator surfaces may reduce cooling

efficiency and radiator life expectancy. It is

extremely important to evacuate/purge all air within

the cooling system before replacing the radiator cap.

Engine coolant must not only maintain proper freeze

protection levels but also maintain proper corrosion

inhibitor levels. Please contact the coolant

manufacture for specifics on testing methods and

suggested coolant maintenance intervals.

*(using manufactures extender additive to system at

3 years or 6000 hours)

5.3

MAINTENANCE AFTER

INITIAL 50 HOURS OF

OPERATION

After the initial 50 hours of operation, the following

maintenance actions are required to eliminate

contaminants from the system:

1. Clean the return line orifice and change the

strainer.

2. Change the compressor fluid filter.

3. Check the Engine Operator’s Manual for ser-

vice requirements.

4. Check the fuel filter for water.

5. Confirm that the sump cover bolts are tight-

ened to 160 lb-ft (215N•m).

5.4

MAINTENANCE EVERY 50

HOURS

1. Inspect air filter elements and replace if nec-

essary.

2. Check the fuel filter for water.

5.5

MAINTENANCE EVERY 100

HOURS

1. Clean the radiator and cooler exterior sur-

faces.

2. Check the Engine Operator’s Manual for ser-

vice requirements.

5.6

MAINTENANCE EVERY 250

HOURS

1. Check fan belt tension.

2. Clean the radiator and cooler exterior sur-

faces. (Where dust and other atmospheric

contaminants are present, it might be neces-

sary to clean these parts more frequently.)

3. Check the Engine Operator’s Manual for ser-

vice requirements.

4. Change the engine oil and filter.:

5. Change the compressor fluid if it is not Sul-

lair AWF

a.

Run the compressor for five to ten minutes to

warm the fluid.

b.

Shut the compressor down and relieve all

internal pressure.

c.

Drain the fluid sump by removing the plug, or

opening the valve at the bottom of the sump

tank.

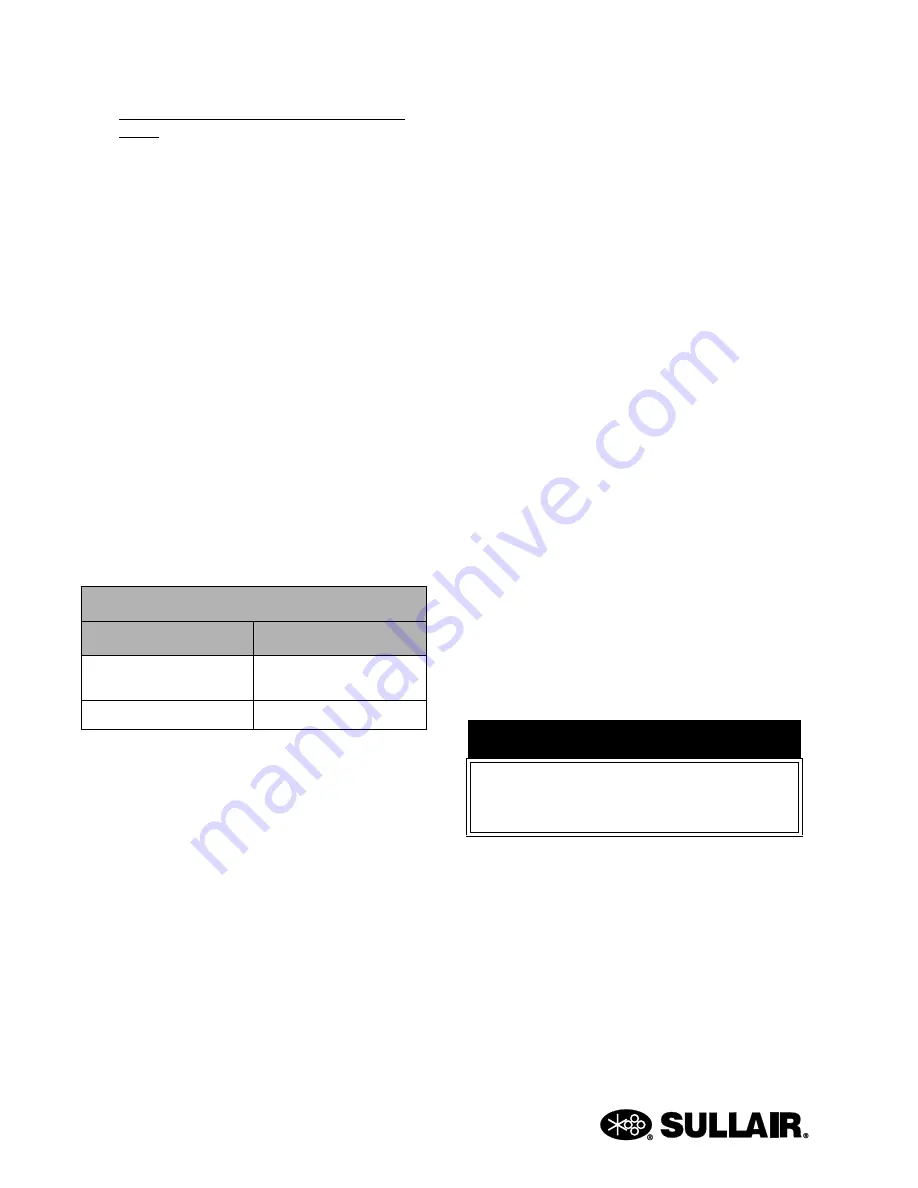

Coolant Service Life

Coolant Type

Service Life

Mobil Delvac EXTENDED

LIFE Coolant/Antifreeze

*Six Years/12,000 Hours

Caterpillar ELC

*Six Years/12,000 Hours

NOTE

Summary of Contents for 300HH

Page 17: ...SECTION 1 15 Safety Symbols 2 ...

Page 18: ...SECTION 1 16 Safety Symbols 3 ...

Page 49: ...SECTION 2 300HH 375 375H 375HH 425 AND 425H USER MANUAL R00 47 2 9 WIRING DIAGRAM ...

Page 60: ...NOTES 58 ...

Page 79: ...NOTES ...