SECTION 5

300HH, 375, 375H, 375HH, 425 AND 425H USER MANUAL R00

65

E

LEMENT

I

NSPECTION

1. Insert a bright light source into the element

and look for any light leaks which indicate

the presence of damage (holes, cracks, etc.)

2. Inspect all gaskets and gasket contact sur-

faces of the housing and replace any dam-

aged ones.

3. Store clean elements for later use in a clean

container.

4. After installing the element, inspect and

tighten all air inlet connections before operat-

ing the compressor.

S

EPARATOR

E

LEMENT

R

EPLACEMENT

Refer to

. When compressor fluid

carryover is evident, after replacing or inspecting the

fluid return line strainer and orifice, the blowdown

valve and checking the oil; and all are in satisfactory

condition, the separator element must be replaced

with Kit number 250034-087 (element for air/fluid

separator).

1. Disconnect all sump cover piping connec-

tions to permit removal (return line, service

line, etc.).

2. Remove the fluid return line from the fitting

on the cover.

3. Remove the eight (8) cover bolts and wash-

ers and lift the cover off the sump.

4. Remove the separator element.

5. Scrape the old gasket material from the

cover and the flange on the sump. Do not

allow the scrapings to fall into the tank.

6. Install the new element.

7. Replace the sump cover and bolts. Lightly

tighten all the bolts and then gradually

tighten them alternating between bolts which

are diagonally opposite each other. Torque

the bolts to 160 ft-lbs (215 N•m).

8. Reconnect all piping. The fluid return line

tube should extend to the bottom of the sep-

arator element which will ensure proper

return line flow.

9. Clean the fluid return line strainer and clear

the orifice before starting the compressor.

10. After 24 hours of operation, tighten the sump

cover bolts to the value given in step 7.

P

ROCEDURE

F

OR

S

ETTING

S

PEED

A

ND

P

RESSURE

C

ONTROLS

O

N

P

ORTABLE

C

OMPRESSORS

E

QUIPPED

W

ITH

P

OPPET

V

ALVES

. Before adjusting

the compressor’s control system, the rated full-load

pressure and the high/low rpm settings must be

determined. This information is provided in

or can be obtained by contacting a Sullair

representative.

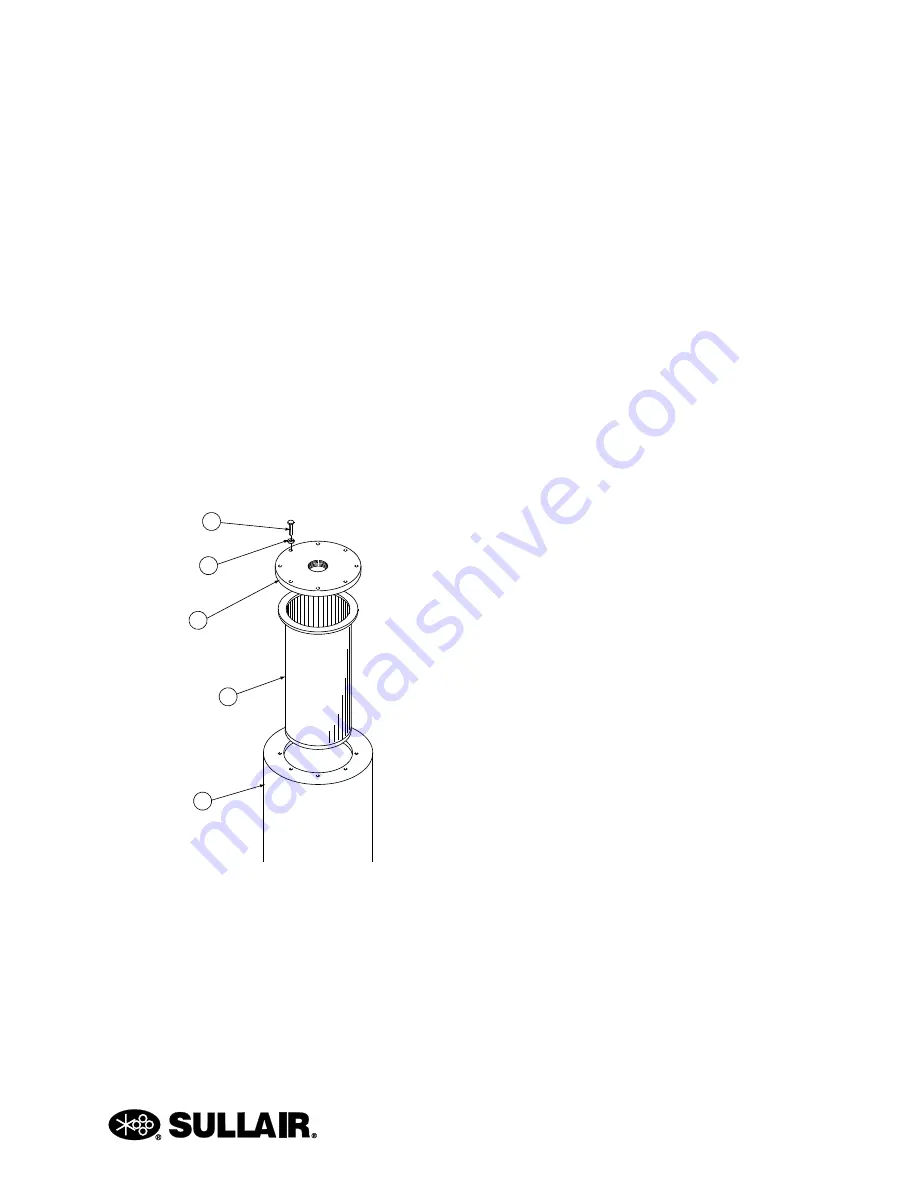

1

2

3

4

5

SU_0000670

1. Capscrew

2. Washer

3. Cover

4. Separator Element with Gaskets

5. Receiver Tank

Figure 5-3: Air/Fluid Separator

Summary of Contents for 300HH

Page 17: ...SECTION 1 15 Safety Symbols 2 ...

Page 18: ...SECTION 1 16 Safety Symbols 3 ...

Page 49: ...SECTION 2 300HH 375 375H 375HH 425 AND 425H USER MANUAL R00 47 2 9 WIRING DIAGRAM ...

Page 60: ...NOTES 58 ...

Page 79: ...NOTES ...