300HH, 375, 375H, 375HH, 425 AND 425H USER MANUAL R00

SECTION 5

70

5.9

TROUBLE SHOOTING

The following Trouble Shooting chart is based upon

data obtained from factory tests and information from

the field. It lists symptoms, probable causes and

remedies. This chart does not cover all possible

malfunctions or cases of abnormal operation. Before

undertaking repairs or replacement actions, analyze

all of the available data.

Performing a detailed visual inspection in all cases

can prevent additional damage or abnormal

operation.

Always:

1. Check for loose wiring or connections.

2. Check for damaged piping.

3. Check for heat damage to parts (electrical

short circuits can cause heat damage) which

can appear as discolorations or the presence

of a burnt odor.

If the troubleshooting remedy does not work, or the

malfunction is not covered in this Trouble Shooting

chart, contact your nearest Sullair representative or

Sullair for technical assistance.

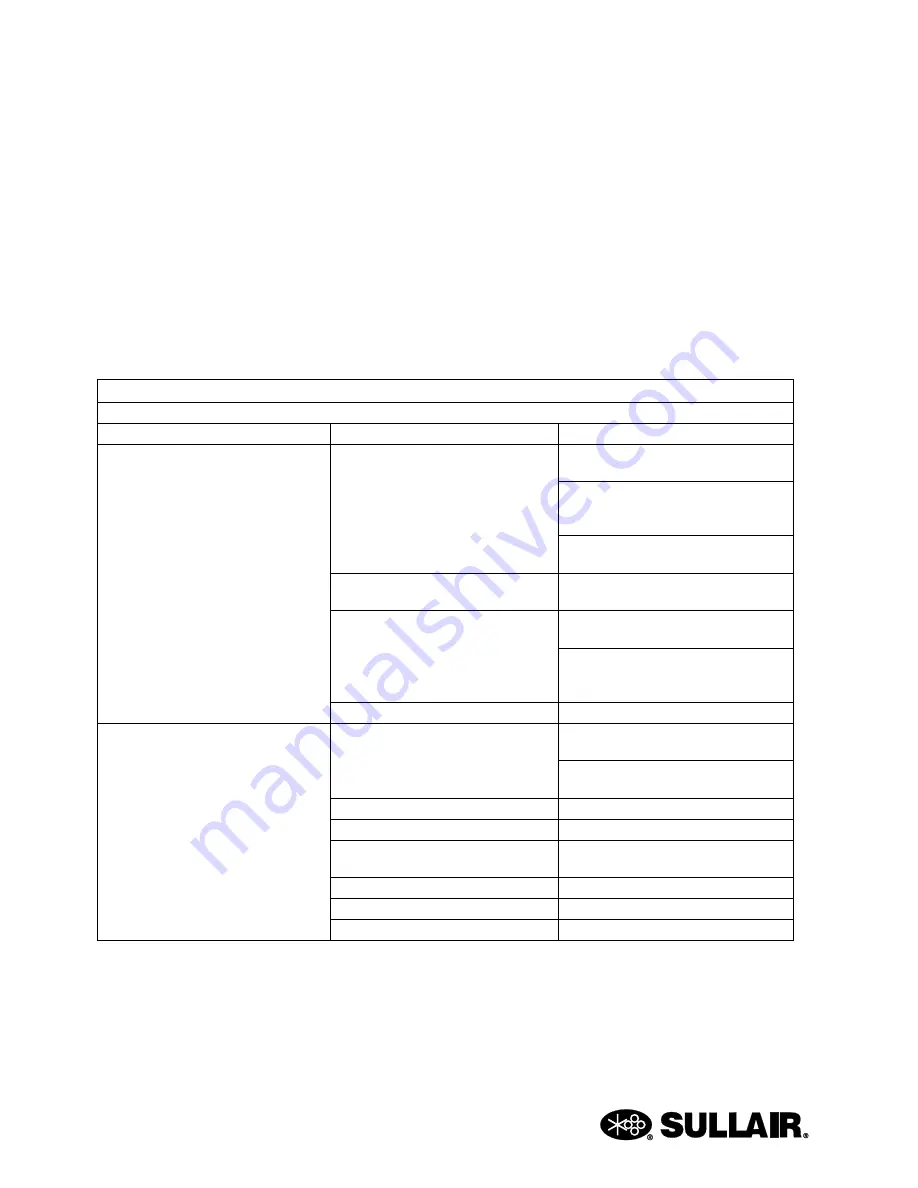

Table 5-1: Troubleshooting

ENGINE STOPS, DOES NOT CRANK OR CRANKS BUT DOES NOT START

SYMPTOM

PROBABLE CAUSE

REMEDY

NO SSAM FLASH CODE

Low voltage or battery disconnected Check battery cables and tighten if

loose

Check ground wire for proper

attachment to frame. Tighten if

required.

Recharge or replace battery if

required.

Blown fuse in wiring harness

Remove and inspect fuse. Replace if

necessary.

Instrument panel connectors loose

or disconnected.

Check instrument panel connectors

and reattach if required

Check instrument panel wires for

broken connections or corrosion.

Clean and/or replace if damaged.

Faulty SSAM module

Replace the module

SSAM FLASH CODE: ONE FLASH

Compressor temperature switch is

open

Check wiring connection to the switch

and tighten if loose

Check switch continuity to ground and

replace if necessary

Low receiver tank fluid level

Add fluid to receiver tank as required

Loose or broken fan belt

Tighten or replace belt

Cooling air flow is insufficient, dirty

fluid cooler core

Clean core thoroughly and check for

proper ventilation

Clogged compressor fluid filter

Change fluid filter element

Faulty fluid thermostat

Change fluid thermostat element

Plugged fluid cooler tube (internal)

Replace cooler

Summary of Contents for 300HH

Page 17: ...SECTION 1 15 Safety Symbols 2 ...

Page 18: ...SECTION 1 16 Safety Symbols 3 ...

Page 49: ...SECTION 2 300HH 375 375H 375HH 425 AND 425H USER MANUAL R00 47 2 9 WIRING DIAGRAM ...

Page 60: ...NOTES 58 ...

Page 79: ...NOTES ...