Section 4

COMPRESSOR SYSTEMS

11

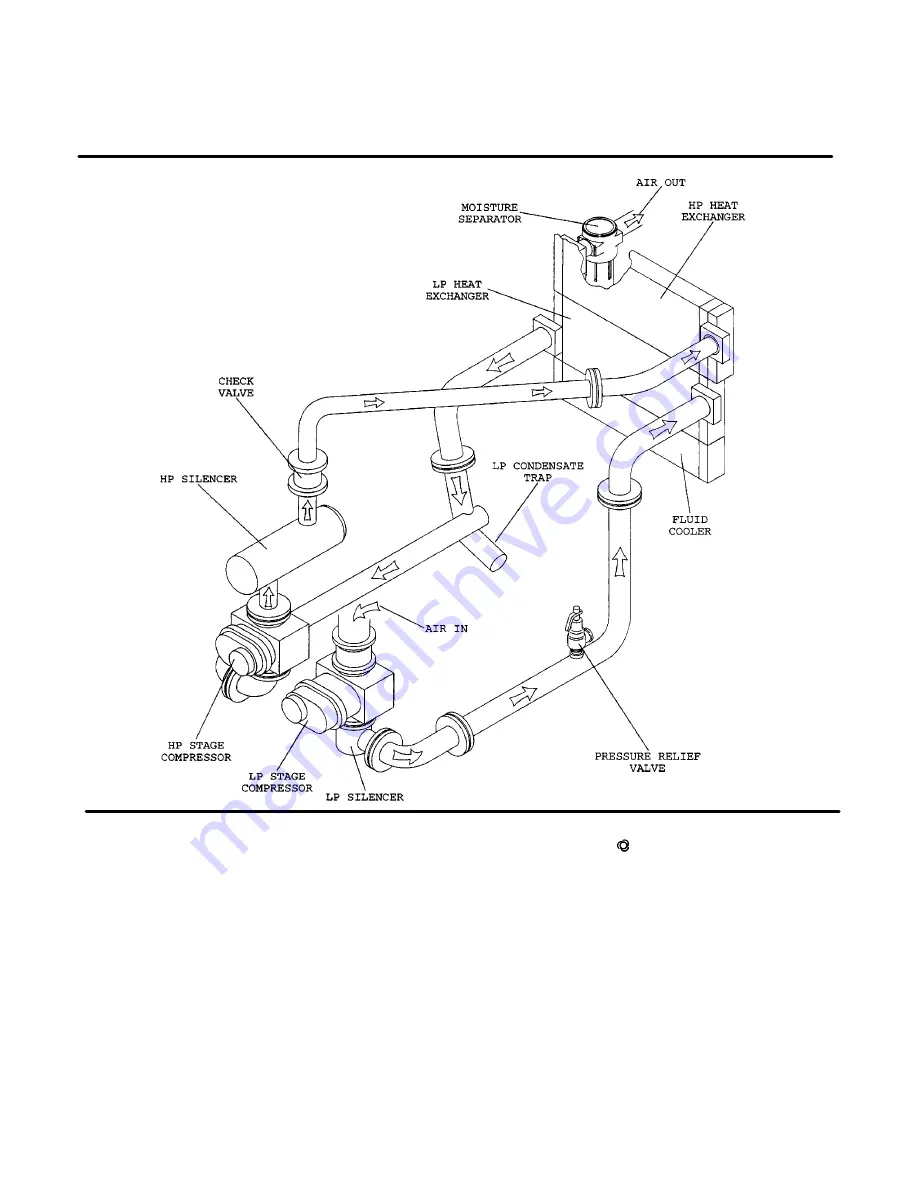

4---4 LP and HP Silencing/Discharge Air and Cooling Systems

A decrease in compressor inlet pressure, caused

by the collected airborne dirt, is sensed by the Su-

pervisor

II

and a filter maintenance announcement

is displayed.

4.5 LOAD/UNLOAD CAPACITY CONTROL SYSTEM,

FUNCTIONAL DESCRIPTION

Refer to Figure

. The purpose of the capacity

control system is to regulate the compressed air

supply to the demand. It consists of an inlet

throttling valve and hydraulic actuator assembly,

and a discharge blowdown valve and muffler as-

sembly, all controlled by the Supervisor

II

. The dif-

ferent phases of operation are described below (for

illustration purposes, 100 psi service operation will

be used):

START MODE -- 0 TO 5 PSIG (0 TO 0.34 BAR)

When the

“I”

or

“

”

pads are depressed, the unit

starts. The inlet valve cylinder control solenoid

valve is deenergized. The blowdown valve remains

open, reducing air compression at the HP pipe-

work, and the inlet valve remains nearly closed (hy-

dro actuator retracted), nearly shutting off inlet air

to the unit.

FULL LOAD MODE -- 75 TO 100 PSIG (5.2--6.9

BAR)

After a two second interval, the Supervisor

II

ener-

gizes the inlet valve cylinder control solenoid valve

which opens the inlet valve (hydro actuator ex-

tended), and closes the blowdown valve via the lim-

it switch, allowing the package to intake and com-

press at 100% capacity.

Summary of Contents for DR-13 Series

Page 6: ...NOTES ...

Page 14: ...8 NOTES ...

Page 18: ...Section 4 COMPRESSOR SYSTEMS 12 Figure 4 5 Piping and Instrumentation Diagram Air cooled ...

Page 21: ...Section 5 SUPERVISOR II 15 Figure 5 1 Supervisor II Panel ...

Page 28: ...22 NOTES ...

Page 32: ...26 NOTES ...

Page 42: ...Section 7 MAINTENANCE 36 Table 1 Installation Data ...

Page 46: ...40 NOTES ...

Page 48: ...Section 9 ILLUSTRATIONS AND PARTS LIST 42 9 3 COMPRESSOR MOTOR AND FRAME ...

Page 50: ...Section 9 ILLUSTRATIONS AND PARTS LIST 44 9 4 AIR INLET SYSTEM ...

Page 52: ...Section 9 ILLUSTRATIONS AND PARTS LIST 46 9 5 COOLER ASSEMBLY ...

Page 54: ...Section 9 ILLUSTRATIONS AND PARTS LIST 48 9 6 LP HOT LP COLD ...

Page 56: ...Section 9 ILLUSTRATIONS AND PARTS LIST 50 9 7 HP DISCHARGE ...

Page 58: ...Section 9 ILLUSTRATIONS AND PARTS LIST 52 9 8 LUBE SYSTEM ...

Page 60: ...Section 9 ILLUSTRATIONS AND PARTS LIST 54 9 9 ELECTRICAL BOX ...

Page 62: ...Section 9 ILLUSTRATIONS AND PARTS LIST 56 9 10 CONTROL SYSTEM CONDENSATE DRAIN ...

Page 64: ...Section 9 ILLUSTRATIONS AND PARTS LIST 58 9 11 CANOPY ...

Page 66: ...Section 9 ILLUSTRATIONS AND PARTS LIST 60 9 12 DECALS ...

Page 68: ...Section 9 ILLUSTRATIONS AND PARTS LIST 62 9 12 DECALS ...

Page 70: ...Section 9 ILLUSTRATIONS AND PARTS LIST 64 9 12 DECALS ...

Page 72: ...Section 9 ILLUSTRATIONS AND PARTS LIST 66 9 13 DECAL LOCATIONS ...

Page 74: ...Section 9 ILLUSTRATIONS AND PARTS LIST 68 9 13 DECAL LOCATIONS ...

Page 76: ...Section 9 ILLUSTRATIONS AND PARTS LIST 70 9 13 DECAL LOCATIONS ...

Page 78: ...Section 9 ILLUSTRATIONS AND PARTS LIST 72 9 14 WIRING DIAGRAM ...

Page 79: ...NOTES ...