Section 5

SUPERVISOR

II

20

P2 > UNLD -- --> load solenoid turned off

P2 < LOAD -- --> load solenoid turned on

POWER FAILURE RESTART

If the restart timer (RST TIME parameter) is dis-

abled the compressor will not try to start after a

power up. If this time is set to a value the machine

will go into standby after power up. When the line

pressure drops below the load setpoint, the restart

timer will start timing. When the timer expires the

machine will start.

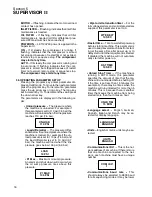

SEQUENCING MODES

The following is a brief description of sequencing

modes, for details see the Supervisor II Sequenc-

ing & Protocol Manual (P/N 02250057---696)

.

S

DISABLED

--- Responds to status and

parameter change messages via the

RS485 network but will not respond to

start, stop, load or unload messages.

S

REMOTE

--- Responds to status and pa-

rameter change messages but will not re-

spond to start, stop, load or unload mes-

sages. The remote inputs and outputs are

enabled (start/stop, load/unload, master/

local).

S

SLAVE

--- Will respond to all messages,

but will not start or load unless comman-

ded to do so by a message. This mode is

used to control the machine from a master

computer.

S

HOURS

--- Sends status message about

once a second, starts, loads and unloads

machines based on sequencing hours.

S

COM ID #

--- Sends status message

about once a second, starts, loads and un-

loads machines based on machine Com

ID#.

5.7 SUPERVISOR

II

OUTPUT RELAYS

RELAY

OPERATION

RUN RELAY (K1)

Contact closure energizes the compressor starter.

*---DELTA (K2)

A timed contact used to provide wye---delta transition

time. Not used on DS---13 Series.

UNLOAD/LOAD (K3)

Controls ON LOAD/OFF LOAD operaton of the load

control solenoid valve.

COMMON FAULT (K4)

May be used to provide remote indication of any pre---

alarm, maintenance or fault shutdown condition.

ELECTRIC DRAIN VALVE (K5)

Controls a solenoid valve to provide automatic con-

densate removal.

FULL LOAD/MODULATE (K6)

Used with sequencing feature.

NOTE: All output relays will handle 8 amperes at 120/240 VAC.

Parameter

Value Range

Notes

Load P2

75 --- 140 psi

Load pressure setting

(5.2 --- 9.7 bar)

Unload P2

85 --- 150 psi

Unload pressure setting

(5.9 --- 10.3 bar)

Max P2

160 psi

System shutdown pressure setting

(11 bar)

Unload Time

10---60 Min.

Time lapse to system shutdown on

AUTO

mode

Table 5---1

Electric DrainInterval

0---10 Min.

0---10 Sec.

Duration

Summary of Contents for DR-13 Series

Page 6: ...NOTES ...

Page 14: ...8 NOTES ...

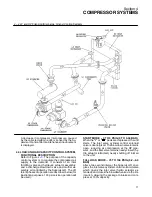

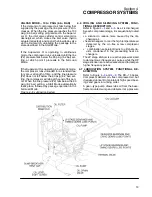

Page 18: ...Section 4 COMPRESSOR SYSTEMS 12 Figure 4 5 Piping and Instrumentation Diagram Air cooled ...

Page 21: ...Section 5 SUPERVISOR II 15 Figure 5 1 Supervisor II Panel ...

Page 28: ...22 NOTES ...

Page 32: ...26 NOTES ...

Page 42: ...Section 7 MAINTENANCE 36 Table 1 Installation Data ...

Page 46: ...40 NOTES ...

Page 48: ...Section 9 ILLUSTRATIONS AND PARTS LIST 42 9 3 COMPRESSOR MOTOR AND FRAME ...

Page 50: ...Section 9 ILLUSTRATIONS AND PARTS LIST 44 9 4 AIR INLET SYSTEM ...

Page 52: ...Section 9 ILLUSTRATIONS AND PARTS LIST 46 9 5 COOLER ASSEMBLY ...

Page 54: ...Section 9 ILLUSTRATIONS AND PARTS LIST 48 9 6 LP HOT LP COLD ...

Page 56: ...Section 9 ILLUSTRATIONS AND PARTS LIST 50 9 7 HP DISCHARGE ...

Page 58: ...Section 9 ILLUSTRATIONS AND PARTS LIST 52 9 8 LUBE SYSTEM ...

Page 60: ...Section 9 ILLUSTRATIONS AND PARTS LIST 54 9 9 ELECTRICAL BOX ...

Page 62: ...Section 9 ILLUSTRATIONS AND PARTS LIST 56 9 10 CONTROL SYSTEM CONDENSATE DRAIN ...

Page 64: ...Section 9 ILLUSTRATIONS AND PARTS LIST 58 9 11 CANOPY ...

Page 66: ...Section 9 ILLUSTRATIONS AND PARTS LIST 60 9 12 DECALS ...

Page 68: ...Section 9 ILLUSTRATIONS AND PARTS LIST 62 9 12 DECALS ...

Page 70: ...Section 9 ILLUSTRATIONS AND PARTS LIST 64 9 12 DECALS ...

Page 72: ...Section 9 ILLUSTRATIONS AND PARTS LIST 66 9 13 DECAL LOCATIONS ...

Page 74: ...Section 9 ILLUSTRATIONS AND PARTS LIST 68 9 13 DECAL LOCATIONS ...

Page 76: ...Section 9 ILLUSTRATIONS AND PARTS LIST 70 9 13 DECAL LOCATIONS ...

Page 78: ...Section 9 ILLUSTRATIONS AND PARTS LIST 72 9 14 WIRING DIAGRAM ...

Page 79: ...NOTES ...