Section 2

INSTALLATION

6

drain traps is also recommended throughout.

No piping loads or moments should be transmitted

to the air connections provided with the package.

Condensate drains shall be connected to a non---

pressurized gravity feed drain. If the compressor

drains are manifolded together, care should be tak-

en to insure that this drain is not pressurized when

the machine condensate drains (both automatic or

manual) are in operation.

All condensate should be disposed of in accor-

dance with local governing laws.

2.4 SHAFT COUPLING ALIGNMENT CHECK

The compressor unit and motor are rigidly con-

nected via a cast adaptor piece which maintains

the shaft coupling in proper alignment. It is recom-

mended that prior to initial startup shaft alignment

be checked, and all coupling fasteners are

checked for proper tensioning. Refer to the Cou-

pling Service Procedures included in the Mainte-

nance section of this manual.

2.5 FLUID LEVEL CHECK

The package oil sump is supplied with the proper

charge of lube oil --- a level reaching 75% of the

sight glass should be visible when the compressor

unit is shut down. Check this level after initial instal-

lation and periodically thereafter.

2.6 ELECTRICAL PREPARATION

Interior electrical wiring is assembled at the factory.

Required customer wiring is minimal (i.e., isolation

switches, fusible disconnects, etc.), but should be

done by a qualified electrician, in compliance with

OSHA, NEC, and any other applicable codes. A

wiring diagram is provided with the package docu-

mentation.

DANGER

!

Lethal shock hazard inside.

Disconnect all power at source before opening or

servicing.

1. Make sure incoming field voltage matches re-

quired package voltage.

2. Check starter overload and heater sizes --- see

Electrical section in Parts Manual.

3. Check all electrical connections for tightness.

4. Check motor rotation, as explained in Section

2.7.

2.7 MOTOR ROTATION CHECK

After the electrical installation has been done, it is

necessary to check the direction of motor rotation.

Pull out the EMERGENCY STOP button and press

once, quickly and in succession, the

“I”

and

“O”

pads. This action will “Bump Start” the motor for a

very short time. When looking at the motor from the

rear end, the driveline should be rotating counter-

clockwise (opposite shaft end). If the reversed ro-

tation is noted, disconnect the power to the starter

and exchange any two of the three power input

leads, then re---check rotation. A “Direction of Ro-

tation” nameplate is located on the top of the com-

pressor/motor adaptor piece.

Summary of Contents for DR-13 Series

Page 6: ...NOTES ...

Page 14: ...8 NOTES ...

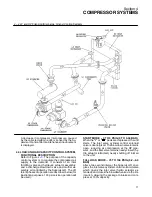

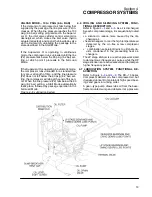

Page 18: ...Section 4 COMPRESSOR SYSTEMS 12 Figure 4 5 Piping and Instrumentation Diagram Air cooled ...

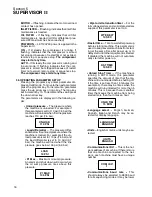

Page 21: ...Section 5 SUPERVISOR II 15 Figure 5 1 Supervisor II Panel ...

Page 28: ...22 NOTES ...

Page 32: ...26 NOTES ...

Page 42: ...Section 7 MAINTENANCE 36 Table 1 Installation Data ...

Page 46: ...40 NOTES ...

Page 48: ...Section 9 ILLUSTRATIONS AND PARTS LIST 42 9 3 COMPRESSOR MOTOR AND FRAME ...

Page 50: ...Section 9 ILLUSTRATIONS AND PARTS LIST 44 9 4 AIR INLET SYSTEM ...

Page 52: ...Section 9 ILLUSTRATIONS AND PARTS LIST 46 9 5 COOLER ASSEMBLY ...

Page 54: ...Section 9 ILLUSTRATIONS AND PARTS LIST 48 9 6 LP HOT LP COLD ...

Page 56: ...Section 9 ILLUSTRATIONS AND PARTS LIST 50 9 7 HP DISCHARGE ...

Page 58: ...Section 9 ILLUSTRATIONS AND PARTS LIST 52 9 8 LUBE SYSTEM ...

Page 60: ...Section 9 ILLUSTRATIONS AND PARTS LIST 54 9 9 ELECTRICAL BOX ...

Page 62: ...Section 9 ILLUSTRATIONS AND PARTS LIST 56 9 10 CONTROL SYSTEM CONDENSATE DRAIN ...

Page 64: ...Section 9 ILLUSTRATIONS AND PARTS LIST 58 9 11 CANOPY ...

Page 66: ...Section 9 ILLUSTRATIONS AND PARTS LIST 60 9 12 DECALS ...

Page 68: ...Section 9 ILLUSTRATIONS AND PARTS LIST 62 9 12 DECALS ...

Page 70: ...Section 9 ILLUSTRATIONS AND PARTS LIST 64 9 12 DECALS ...

Page 72: ...Section 9 ILLUSTRATIONS AND PARTS LIST 66 9 13 DECAL LOCATIONS ...

Page 74: ...Section 9 ILLUSTRATIONS AND PARTS LIST 68 9 13 DECAL LOCATIONS ...

Page 76: ...Section 9 ILLUSTRATIONS AND PARTS LIST 70 9 13 DECAL LOCATIONS ...

Page 78: ...Section 9 ILLUSTRATIONS AND PARTS LIST 72 9 14 WIRING DIAGRAM ...

Page 79: ...NOTES ...