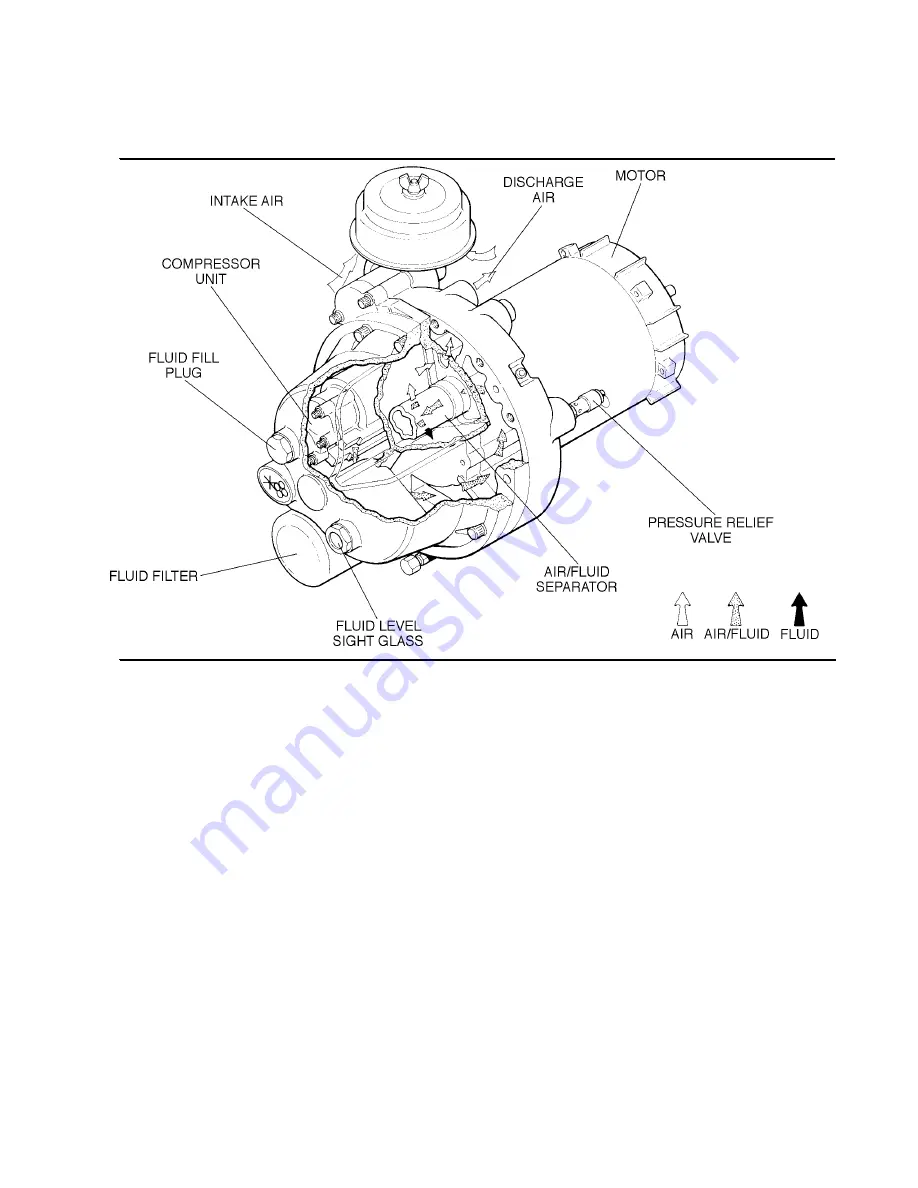

Section 2

DESCRIPTION

7

Figure 2--2 Encapsulated Compressor System

2.6 CONTROL SYSTEM, FUNCTIONAL DE-

SCRIPTION

The purpose of the compressor control system is to

maintain compressor capacity to meet the system

demand.

It consists of an

inlet valve, solenoid valve, con-

trol lines

and the

motor start selector switch

.

The selector switch has three settings:

MANUAL/

START

,

OFF/RESET

and

AUTOMATIC START/

STOP

.

MANUAL MODE

The compressor motor will start and the air control

solenoid valve will be energized. The compressor

will start to deliver compressed air. When no air is

being used, the service line pressure rises to the

setting (cut--out pressure) of the pressure switch.

The system pressure switch opens, interrupting the

electrical power to the solenoid valve. The solenoid

valve allows control air to the inlet valve, unloading

the compressor and the motor continues to run.

When the line pressure drops to the low setting of

the pressure switch, the pressure switch closes, re--

energizing the normally open solenoid valve and al-

lowing the compressor to load again.

OFF/RESET MODE

The compressor motor, if running, will stop if the off/

reset position is selected. If the compressor during

normal running has a fault caused by either overload

or high discharge temperature, the compressor will

stop. After a fault has been cleared, the compressor

can not be restarted unless the Off/Reset mode is

selected on the selector switch, prior to starting in

any other mode of operation.

AUTOMATIC MODE

In the automatic mode of operation, the air system

pressure switch opens, interrupting the electrical

power to the air control solenoid valve; the compres-

sor unloads and the motor will stop. The motor will

automatically restart when the compressor sump

pressure drops to the minimum setpoint on the

sump pressure switch and the line pressure drops

below the setpoint of the air pressure switch.

Summary of Contents for ES-6 series

Page 6: ...NOTES...

Page 30: ...Section 7 ILLUSTRATIONS AND PARTS LIST 24 ES 6 COMPRESSOR ASSEMBLY EXPLODED VIEW 5 5 AND 7 5KW...

Page 32: ...Section 7 ILLUSTRATIONS AND PARTS LIST 26 7 3 FLUID MANAGEMENT SYSTEM...

Page 34: ...Section 7 ILLUSTRATIONS AND PARTS LIST 28 7 4 INLET FILTER...

Page 36: ...Section 7 ILLUSTRATIONS AND PARTS LIST 30 7 5 SEAL AND DRIVE GEAR...

Page 38: ...Section 7 ILLUSTRATIONS AND PARTS LIST 32 7 6 MOTOR HOUSING AND PARTS 7 5 10HP 5 5 7 5KW ONLY...

Page 42: ...Section 7 ILLUSTRATIONS AND PARTS LIST 36 7 8 COMPRESSOR SYSTEM...

Page 44: ...Section 7 ILLUSTRATIONS AND PARTS LIST 38 7 9 INLET CONTROL...

Page 46: ...Section 7 ILLUSTRATIONS AND PARTS LIST 40 7 10 CONTROL BOX...

Page 48: ...Section 7 ILLUSTRATIONS AND PARTS LIST 42 7 10 CONTROL BOX...

Page 52: ...Section 7 ILLUSTRATIONS AND PARTS LIST 46 7 12 FRAME CANOPY AND PARTS...

Page 56: ...Section 7 ILLUSTRATIONS AND PARTS LIST 50 7 14 WYE DELTA ELECTRIC BOX ES 6...

Page 58: ...Section 7 ILLUSTRATIONS AND PARTS LIST 52 7 15 DECAL GROUP 7 8 9 11 12...

Page 60: ...Section 7 ILLUSTRATIONS AND PARTS LIST 54 7 15 DECAL GROUP 13...

Page 62: ...Section 7 ILLUSTRATIONS AND PARTS LIST 56 7 16 WIRING DIAGRAM SINGLE PHASE 60Hz...

Page 63: ...Section 7 ILLUSTRATIONS AND PARTS LIST 57 7 17 WIRING DIAGRAM THREE PHASE 60Hz...

Page 64: ...Section 7 ILLUSTRATIONS AND PARTS LIST 58 7 18 WIRING DIAGRAM 50 Hz...

Page 65: ...Section 7 ILLUSTRATIONS AND PARTS LIST 59 7 19 WIRING DIAGRAM 50 Hz WYE DELTA...

Page 66: ...NOTES...

Page 67: ...NOTES...