Section 6

MAINTENANCE

20

COIL REPLACEMENT

1. Remove the retaining cap, nameplate and cover.

2. Slip the yoke containing the coil and sleeves off

the solenoid base subassembly.

3. Reassemble in reverse order of disassembly.

WARNING

!

Before doing compressor maintenance, discon-

nect compressor from power source and lock out

power source. Isolate compressor from line pres-

sure by closing recommended discharge shut--

off valve and releasing all internal pressure from

compressor.

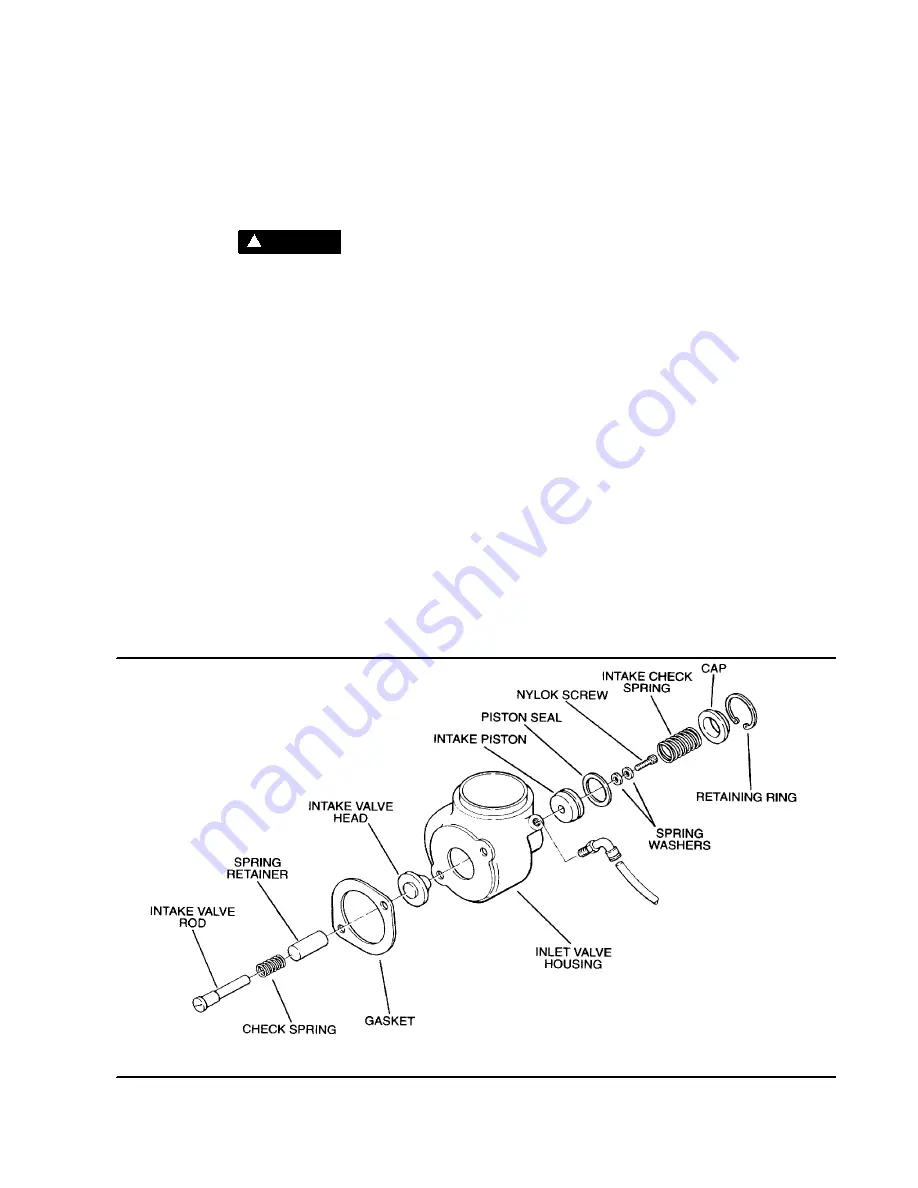

INLET CONTROL VALVE

. T he only par t s whic h nor m ally

require replacement are the piston seal on the in-

take valve piston and gasket. Follow this procedure

for inlet control maintenance.

1. Remove the inlet filter assembly.

2. Disconnect tubing from intake control housing at

90

q

elbow.

3. Remove the two (2) 3/8” ferry head capscrews

securing the intake control housing to the inlet

plate.

4. Remove intake control housing assembly and

gasket.

5. Remove retaining ring, cap and intake check

spring from intake housing bore.

6. Remove socket head capscrew, washers, and

check spring from intake valve rod.

7. Remove intake valve from valve housing. Re-

move intake valve rod, check spring, spring re-

tainer and intake valve head.

8. Remove intake piston from intake/inlet control

housing. Remove and discard old piston seal

from intake piston.

9. Clean intake housing gasket surface and internal

piston bore.

10. Lubricate internal piston bore using lubricant sup-

plied with kit.

11. Install new piston seal onto piston.

12. Reinstall intake valve rod, check spring, spring re-

tainer and intake valve head into intake control

housing. Install assembled intake piston into in-

take control bore and onto intake valve rod.

13. Install washers. Apply screw lock adhesive pro-

vided in kit to socket head capscrew. Replace

socket head capscrew into the valve rod and

torque socket head capscrew to 18 to 24 in.--lbs.

(2.0 to 2.7Nm).

14. Install intake check spring, cap and retaining ring.

15. Replace gasket and reinstall the whole inlet con-

trol valve assembly.

16. Apply screw lock adhesive to inlet control housing

assembly ferry head capscrews and install.

Torque to 30 ft.--lbs. (40.7Nm).

17. Reconnect tubing to inlet control valve housing at

90

q

elbow.

Figure 6--7 Inlet Control Valve

* Repair Kit P/N 02250045--287

*

*

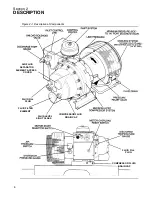

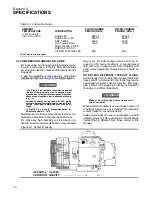

Summary of Contents for ES-6 series

Page 6: ...NOTES...

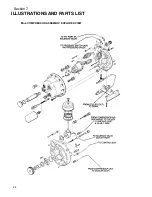

Page 30: ...Section 7 ILLUSTRATIONS AND PARTS LIST 24 ES 6 COMPRESSOR ASSEMBLY EXPLODED VIEW 5 5 AND 7 5KW...

Page 32: ...Section 7 ILLUSTRATIONS AND PARTS LIST 26 7 3 FLUID MANAGEMENT SYSTEM...

Page 34: ...Section 7 ILLUSTRATIONS AND PARTS LIST 28 7 4 INLET FILTER...

Page 36: ...Section 7 ILLUSTRATIONS AND PARTS LIST 30 7 5 SEAL AND DRIVE GEAR...

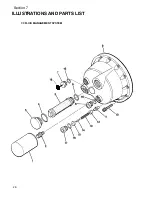

Page 38: ...Section 7 ILLUSTRATIONS AND PARTS LIST 32 7 6 MOTOR HOUSING AND PARTS 7 5 10HP 5 5 7 5KW ONLY...

Page 42: ...Section 7 ILLUSTRATIONS AND PARTS LIST 36 7 8 COMPRESSOR SYSTEM...

Page 44: ...Section 7 ILLUSTRATIONS AND PARTS LIST 38 7 9 INLET CONTROL...

Page 46: ...Section 7 ILLUSTRATIONS AND PARTS LIST 40 7 10 CONTROL BOX...

Page 48: ...Section 7 ILLUSTRATIONS AND PARTS LIST 42 7 10 CONTROL BOX...

Page 52: ...Section 7 ILLUSTRATIONS AND PARTS LIST 46 7 12 FRAME CANOPY AND PARTS...

Page 56: ...Section 7 ILLUSTRATIONS AND PARTS LIST 50 7 14 WYE DELTA ELECTRIC BOX ES 6...

Page 58: ...Section 7 ILLUSTRATIONS AND PARTS LIST 52 7 15 DECAL GROUP 7 8 9 11 12...

Page 60: ...Section 7 ILLUSTRATIONS AND PARTS LIST 54 7 15 DECAL GROUP 13...

Page 62: ...Section 7 ILLUSTRATIONS AND PARTS LIST 56 7 16 WIRING DIAGRAM SINGLE PHASE 60Hz...

Page 63: ...Section 7 ILLUSTRATIONS AND PARTS LIST 57 7 17 WIRING DIAGRAM THREE PHASE 60Hz...

Page 64: ...Section 7 ILLUSTRATIONS AND PARTS LIST 58 7 18 WIRING DIAGRAM 50 Hz...

Page 65: ...Section 7 ILLUSTRATIONS AND PARTS LIST 59 7 19 WIRING DIAGRAM 50 Hz WYE DELTA...

Page 66: ...NOTES...

Page 67: ...NOTES...