Section 6

MAINTENANCE

22

TROUBLESHOOTING

SYMPTOM

PROBABLE CAUSE

REMEDY

LI N E P R E S S U R E R I S E S A B O V E D ef ec t iv e S olenoid Valv e R epair s olenoid v alv e ( s ee

) .

CUT--OUT PRESSURE SETTING

ON PRESSURE SWITCH

Leak In Control System Causing

Check for leaks.

Loss Of Pressure Signals

Defective Pressure Switch

Check that diaphragm and contacts are not

damaged. Replace if necessary.

Inlet Valve Stuck Open

Inspect inlet valve and insure free operation

EXCESSIVE COMPRESSOR

Clogged Return Line

Remove element cover and clean orifice.

FLUID CONSUMPTION

Separator Element Damaged Or

Change separator element.

Not Functioning Properly

Leak In The Lubrication System

Check all pipes, connections and

components.

Excess Fluid Foaming

Drain and change.

Fluid Level Too High

Drain excess.

Shaft Seal Failure

Replace shaft seal.

PRESSURE RELIEF VALVE

Compressor Operating Pressure

See Symptom “Line Pressure Rises Above

OPENS REPEATEDLY

Too High

Cut--out Pressure Setting on Pressure

Switch” above

Defective Pressure Relief Valve

Replace pressure relief valve.

LIQUID WATER IN COMPRESSED

Water Vapor Condensation From Cooling

Remove the water vapor from compressed air prior

AIR LINES

and Compression Occurs Naturally

to distribution through the air system. Check

operation of aftercooler and moisture separator.

Install a compressed air dryer sized for the flow and

dryness level required. (Note: Filters may also be

required to remove particulates, liquid oil aerosols

or for oil vapor removal. Change cartridges as

recommended by the filter manufacturer.) Check all

drain traps routinely to insure their proper

operation. Maintain them regularly.

Summary of Contents for ES-6 series

Page 6: ...NOTES...

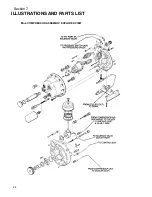

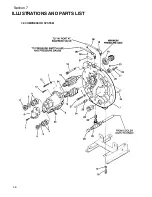

Page 30: ...Section 7 ILLUSTRATIONS AND PARTS LIST 24 ES 6 COMPRESSOR ASSEMBLY EXPLODED VIEW 5 5 AND 7 5KW...

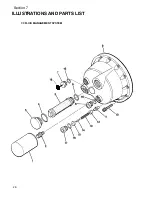

Page 32: ...Section 7 ILLUSTRATIONS AND PARTS LIST 26 7 3 FLUID MANAGEMENT SYSTEM...

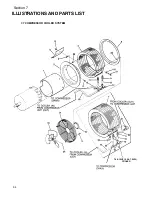

Page 34: ...Section 7 ILLUSTRATIONS AND PARTS LIST 28 7 4 INLET FILTER...

Page 36: ...Section 7 ILLUSTRATIONS AND PARTS LIST 30 7 5 SEAL AND DRIVE GEAR...

Page 38: ...Section 7 ILLUSTRATIONS AND PARTS LIST 32 7 6 MOTOR HOUSING AND PARTS 7 5 10HP 5 5 7 5KW ONLY...

Page 42: ...Section 7 ILLUSTRATIONS AND PARTS LIST 36 7 8 COMPRESSOR SYSTEM...

Page 44: ...Section 7 ILLUSTRATIONS AND PARTS LIST 38 7 9 INLET CONTROL...

Page 46: ...Section 7 ILLUSTRATIONS AND PARTS LIST 40 7 10 CONTROL BOX...

Page 48: ...Section 7 ILLUSTRATIONS AND PARTS LIST 42 7 10 CONTROL BOX...

Page 52: ...Section 7 ILLUSTRATIONS AND PARTS LIST 46 7 12 FRAME CANOPY AND PARTS...

Page 56: ...Section 7 ILLUSTRATIONS AND PARTS LIST 50 7 14 WYE DELTA ELECTRIC BOX ES 6...

Page 58: ...Section 7 ILLUSTRATIONS AND PARTS LIST 52 7 15 DECAL GROUP 7 8 9 11 12...

Page 60: ...Section 7 ILLUSTRATIONS AND PARTS LIST 54 7 15 DECAL GROUP 13...

Page 62: ...Section 7 ILLUSTRATIONS AND PARTS LIST 56 7 16 WIRING DIAGRAM SINGLE PHASE 60Hz...

Page 63: ...Section 7 ILLUSTRATIONS AND PARTS LIST 57 7 17 WIRING DIAGRAM THREE PHASE 60Hz...

Page 64: ...Section 7 ILLUSTRATIONS AND PARTS LIST 58 7 18 WIRING DIAGRAM 50 Hz...

Page 65: ...Section 7 ILLUSTRATIONS AND PARTS LIST 59 7 19 WIRING DIAGRAM 50 Hz WYE DELTA...

Page 66: ...NOTES...

Page 67: ...NOTES...