Section 1

SAFETY

1

1.1 GENERAL

Sullair Corporation and its subsidiaries design and

manufacture all of their products so they can be op-

erated safely. However, the responsibility for safe

operation rests with those who use and maintain

these products. The following safety precautions

are offered as a guide which, if conscientiously fol-

lowed, will minimize the possibility of accidents

throughout the useful life of this equipment.

The compressor should be operated only by those

who have been trained and delegated to do so, and

who have read and understood this Operator’s

Manual. Failure to follow the instructions, proce-

dures and safety precautions in this manual may re-

sult in accidents and injuries.

NEVER

start the compressor unless it is safe to do

so.

DO NOT

attempt to operate the compressor with

a known unsafe condition. Tag the compressor and

render it inoperative by disconnecting and locking

out all power at source or otherwise disabling its

prime mover so others who may not know of the un-

safe condition cannot attempt to operate it until the

condition is corrected.

Install, use and operate the compressor only in full

compliance with all pertinent OSHA regulations

and/or any applicable Federal, State, and Local

codes, standards and regulations.

DO NOT

modify the compressor and/or controls in

any way except with written factory approval.

While not specifically applicable to all types of com-

pressors with all types of prime movers, most of the

precautionary statements contained herein are ap-

plicable to most compressors and the concepts be-

hind these statements are generally applicable to all

compressors.

1.2 PERSONAL PROTECTIVE EQUIPMENT

Prior to installing or operating the compressor, own-

ers, employers and users should become familiar

with, and comply with, all applicable OSHA regula-

tions and/or any applicable Federal, State and Local

codes, standards, and regulations relative to per-

sonal protective equipment, such as eye and face

protective equipment, respiratory protective equip-

ment, equipment intended to protect the extremi-

ties, protective clothing, protective shields and barri-

ers and electrical protective equipment, as well as

noise exposure administrative and/or engineering

controls and/or personal hearing protective equip-

ment.

1.3 PRESSURE RELEASE

A.

Install an appropriate flow--limiting valve between

the service air outlet and the shut--off (throttle)

valve, either at the compressor or at any other point

along the air line, when an air hose exceeding 1/2”

(13mm) inside diameter is to be connected to the

shut--off (throttle) valve, to reduce pressure in case

of hose failure, per OSHA Standard 29 CFR

1926.302(b)(7) and/or any applicable Federal,

State and Local codes, standards and regulations.

B.

When the hose is to be used to supply a manifold,

install an additional appropriate flow--limiting valve

between the manifold and each air hose exceeding

1/2” (13mm) inside diameter that is to be connected

to the manifold to reduce pressure in case of hose

failure.

C.

Provide an appropriate flow--limiting valve at the

beginning of each additional 75 feet (23m) of hose in

runs of air hose exceeding 1/2” (13mm) inside diam-

eter to reduce pressure in case of hose failure.

D.

Flow--limiting valves are listed by pipe size and

rated CFM. Select appropriate valves accordingly,

in accordance with their manufacturer’s recommen-

dations.

E. DO NOT

use air tools that are rated below the

maximum rating of the compressor. Select air tools,

air hoses, pipes, valves, filters and other fittings ac-

cordingly.

DO NOT

exceed manufacturer’s rated

safe operating pressures for these items.

F.

Secure all hose connections by wire, chain or oth-

er suitable retaining device to prevent tools or hose

ends from being accidentally disconnected and ex-

pelled.

G.

Open fluid filler cap only when compressor

is not

running and is not pressurized.

Shut down the

compressor and bleed the sump (receiver) to zero

internal pressure before removing the cap.

H.

Vent all internal pressure prior to opening any

line, fitting, hose, valve, drain plug, connection or

other component, such as filters and line oilers, and

before attempting to refill optional air line anti--icer

systems with antifreeze compound.

I.

Keep personnel out of line with and away from the

discharge opening of hoses or tools or other points

of compressed air discharge.

J.

Use air at pressures less than 30 psig (2.1 bar) for

cleaning purposes, and then only with effective chip

guarding and personal protective equipment per

OSHA Standard 29 CFR 1910.242 (b) and/or any

applicable Federal, State, and Local codes, stan-

dards and regulations.

K. DO NOT

engage in horseplay with air hoses as

death or serious injury may result.

1.4 FIRE AND EXPLOSION

A.

Clean up spills of lubricant or other combustible

substances immediately, if such spills occur.

B.

Shut off the compressor and allow it to cool. Then

keep sparks, flames and other sources of ignition

away and

DO NOT

permit smoking in the vicinity

when checking or adding lubricant or when refilling

air line anti--icer systems with antifreeze compound.

C. DO NOT

permit fluids, including air line anti--icer

system antifreeze compound or fluid film, to accu-

Summary of Contents for ES-6 series

Page 6: ...NOTES...

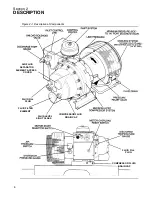

Page 30: ...Section 7 ILLUSTRATIONS AND PARTS LIST 24 ES 6 COMPRESSOR ASSEMBLY EXPLODED VIEW 5 5 AND 7 5KW...

Page 32: ...Section 7 ILLUSTRATIONS AND PARTS LIST 26 7 3 FLUID MANAGEMENT SYSTEM...

Page 34: ...Section 7 ILLUSTRATIONS AND PARTS LIST 28 7 4 INLET FILTER...

Page 36: ...Section 7 ILLUSTRATIONS AND PARTS LIST 30 7 5 SEAL AND DRIVE GEAR...

Page 38: ...Section 7 ILLUSTRATIONS AND PARTS LIST 32 7 6 MOTOR HOUSING AND PARTS 7 5 10HP 5 5 7 5KW ONLY...

Page 42: ...Section 7 ILLUSTRATIONS AND PARTS LIST 36 7 8 COMPRESSOR SYSTEM...

Page 44: ...Section 7 ILLUSTRATIONS AND PARTS LIST 38 7 9 INLET CONTROL...

Page 46: ...Section 7 ILLUSTRATIONS AND PARTS LIST 40 7 10 CONTROL BOX...

Page 48: ...Section 7 ILLUSTRATIONS AND PARTS LIST 42 7 10 CONTROL BOX...

Page 52: ...Section 7 ILLUSTRATIONS AND PARTS LIST 46 7 12 FRAME CANOPY AND PARTS...

Page 56: ...Section 7 ILLUSTRATIONS AND PARTS LIST 50 7 14 WYE DELTA ELECTRIC BOX ES 6...

Page 58: ...Section 7 ILLUSTRATIONS AND PARTS LIST 52 7 15 DECAL GROUP 7 8 9 11 12...

Page 60: ...Section 7 ILLUSTRATIONS AND PARTS LIST 54 7 15 DECAL GROUP 13...

Page 62: ...Section 7 ILLUSTRATIONS AND PARTS LIST 56 7 16 WIRING DIAGRAM SINGLE PHASE 60Hz...

Page 63: ...Section 7 ILLUSTRATIONS AND PARTS LIST 57 7 17 WIRING DIAGRAM THREE PHASE 60Hz...

Page 64: ...Section 7 ILLUSTRATIONS AND PARTS LIST 58 7 18 WIRING DIAGRAM 50 Hz...

Page 65: ...Section 7 ILLUSTRATIONS AND PARTS LIST 59 7 19 WIRING DIAGRAM 50 Hz WYE DELTA...

Page 66: ...NOTES...

Page 67: ...NOTES...