Section 2

DESCRIPTION

11

UNLOAD - IN EXCESS OF 125 PSIG (8.6 BAR)

LINE PRESSURE

When no air is being used,the service line pressure

rises to the setting (cut--out pressure) of the pres-

sure switch. the pressure switch opens, interrupting

the electrical power to the solenoid valve. At this

time, the solenoid valve allows dry sump tank air

pressure or service air pressure through a shuttle

valve to be applied directly to the inlet valve piston

and keep it closed. Simultaneously, the solenoid

valve sends a pneumatic signal to the blowdown

valve. The blowdown valve opens the sump to the

compressor intake reducing the sump pressure to

approximately 25 to 27 psig (1.7to 1.9 bar). The

check valve in the air service line pressure prevents

line pressure from returning to the sump.

When the line pressure drops to the low setting (cut--

in pressure) of the pressure switch (usually 115 psig

[7.9 bar]), the pressure switch closes, re--energizing

the 3--way solenoid valve and allowing the blow-

down valve to close. The re--energized solenoid

valve again prevents pressure from reaching the in-

let valve. The inlet valve is fully open and the com-

pressor delivers full rated capacity. Should the pres-

sure begin to rise, the pressure regulator will resume

its normal function as previously described.

To accommodate varied periods of time when there

are not any air requirements, “Dual--Control” is uti-

lized. This feature allows you to set the compressor

in an automatic position whereby the compressor

will shut down when no compressed air requirement

is present and restart as compressed air is needed.

For applications with varied periods of time when

there are no air requirements, Supervisor’s AUTO-

MATIC mode allows the compressor to shutdown

(time delayed) when no compressed air require-

ment is present and restart as compressed air is

needed.

2.7 AIR

INLET

SYSTEM,

FUNCTIONAL

DE-

SCRIPTION

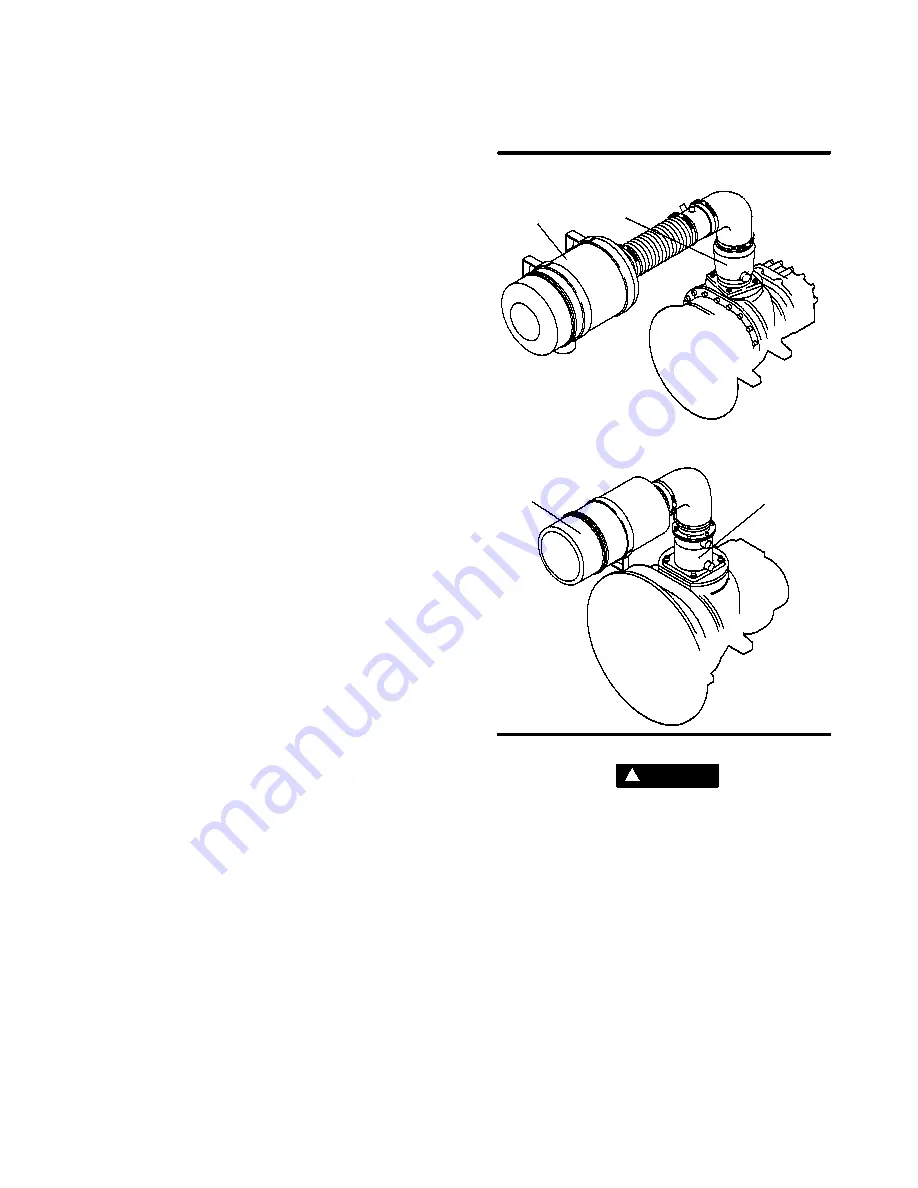

Refer t o F igur e

2 -- 6

. T he C ompr es s or I nlet Sy s t em

consists of a

dry--type air filter

, a

restriction

gauge

and an

air inlet valve

.

The restriction gauge (located on the instrument

panel), indicates the condition of the air filter by

showing red when filter maintenance is required.

The poppet--type modulating air inlet valve directly

controls the amount of air intake to the compressor

in response to the operation of the pressure regula-

tor ( s ee Modulating Mode,

Sec t ion 2.6

[

Standar d

Elec tr o- Mec hanic al

] or

Sec t ion 2.7

[

O ptional Su-

per v is o r I l

]) . T h e inlet v a lv e a ls o a c t s a s a c hec k

valve, thus preventing reverse rotation when the

compressor is shut down.

AIR FILTER

AIR INLET

VALVE

16 SERIES

12 SERIES

AIR FILTER

AIR INLET

VALVE

Figure 2-6 Air Inlet System

WARNING

!

“The Plastic Pipe Institute recommends against the

use of thermoplastic pipe to transport compressed

air or other compressed gases in exposed above

ground locations, e.g. in exposed plant piping.” (I)

Sullube 32 should not be used with PVC piping sys-

tems. It may affect the bond at cemented joints. Cer-

tain other plastic materials may also be affected.

(I) Plastic Pipe Institute, Recommendation B,

Adopted January 19, 1972.

2.8 INSTRUMENT PANEL GROUP, FUNCTIONAL

DESCRIPTION-

STANDARD

ELECTRO-ME-

CHANICAL CONTROLLER

The electro-mechanical controller responds to sig-

nals from traditional pressure switch sensors and

provides

stop/start

,

automatic control, common

fault indication

,

sensor bypass timing

,

wye--

delta transition timing

, and facilitates selectable

Summary of Contents for LS-10 series

Page 18: ...14 NOTES...

Page 22: ...Section 3 SPECIFICATIONS 18 Figure 3 1 Wiring Diagram LS12 LS16 Air cooled Water cooled...

Page 24: ...20 NOTES...

Page 28: ...24 NOTES...

Page 32: ...28 NOTES...

Page 35: ...NOTES...