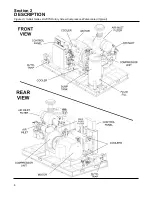

Section 2

DESCRIPTION

8

The receiver is an ASME pressure vessel. A combi-

nation minimum pressure/check valve, located

downstream from the separator, assures a mini-

mum receiver pressure of 170 psig (11.7 bar) during

full load operation. This pressure is necessary for

proper air/fluid separation and proper fluid circula-

tion while supplying air to the system. This valve

also acts as a check valve preventing compressed

air in the service line from bleeding back into the

receiver on shutdown and during operation on the

compressor in an unloaded condition.

A pressure relief valve (located on the wet side of

the separator) is set to open at rated tank pressure.

The compressor is also equipped with high pres-

sure shutdown protection to shut down at high MAX

P1 setpoint. This prevents the relief valve from

opening. High temperature probes are provided to

shut down the compressor.

DO NOT remove caps, plugs, and/or other compo-

nents when compressor is running or pressurized.

Stop compressor and relieve all internal pressure

before doing so.

Fluid is added to the sump via a capped fluid filler

opening, located on the tank to prevent overfilling of

the sump. A sight glass enables the operator to

visually monitor the sump fluid level.

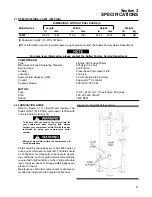

2.6 CAPACITY CONTROL SYSTEM, FUNCTIONAL

DESCRIPTION

. The purpose of the compressor control system

is to regulate the compressor air intake to match the

amount of compressed air being utilized. At 0 to 10

percent air output, the control system will automati-

cally unload the compressor and reduce power con-

sumption. The unload sump pressure can be set

using the unload control regulator valve (150 psig/

10.3 bar).

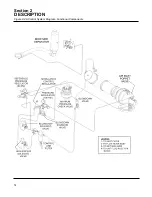

The

Control System

consists of an

inlet poppet

valve

,

startup solenoid valve

,

reference (equal-

izing) pressure regulator

,

blowdown solenoid

valve

,

pneumatic blowdown valve

,

control pres-

sure regulator

,

unload pressure regulator

,

sequencing solenoid valve

, and a

control line fil-

ter

located prior to the controls.

The functional description of the Control System is

described below in five distinct phases of the com-

pressor operation. For explanation purposes, this

description will apply to compressors with an oper-

ating range of 525 to 535 psig (36.1 to 36.8 bar). A

compressor with any other pressure range would

operate in a similar manner except for the stated

pressures.

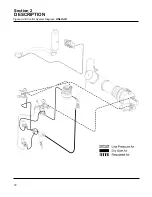

START MODE - TO 170 PSIG (11.7 BAR)

When the compressor start button is depressed, the

pressure will rise from 0 to 170 psig (0 to 11.7 bar).

During this period, the control inlet solenoid is

closed, which keeps the inlet poppet valve closed.

The control pressure regulator is also closed at this

time. After the startup timer times out, the startup

solenoid valve changes state and the reference

pressure regulator controls the pressure signal to

the poppet valve at a maximum 60 psig (4 bar). The

inlet poppet valve opens allowing full airflow to the

compressor inlet and the discharge pressure builds

to approximately 170 psig (11.7 bar). No air is sup-

plied to the system service line during this phase by

the minimum pressure valve. When the discharge

pressure exceeds approximately 170 psig (11.7

bar), the minimum pressure valve may start to open

and allow air to flow to the system service line.

NORMAL OPERATION MODE - 170 TO 525 PSIG

(11.7 TO 36.1 BAR)

When the sump pressure rises above 170 psig

(11.7 bar), the minimum pressure valve opens and

delivers compressed air to the system service line.

From this point on, a line air pressure transducer

continually monitors the air pressure. The control

pressure regulator valve remains closed during this

phase, keeping the inlet poppet valve wide open.

The blowdown solenoid valve also remains closed

during this phase. Flow will occur when the dis-

charge pressure is higher than the line pressure.

The check valve, which is built into the minimum

pressure valve, will prevent back flow into the com-

pressor.

MODULATING MODE - 525 TO 535 PSIG (36.1 TO

36.8 BAR)

If less than the rated capacity of compressed air is

being used, the system service line pressure will

rise above 525 psig (36.1 bar). The control pres-

sure regulator valve gradually opens applying air

pressure to the control side of the inlet poppet

valve, which modulates the position of the inlet pop-

pet valve. This reduces the amount of air entering

the compressor until it matches the amount of air

being utilized. The control system functions contin-

ually in this manner, between the limits of 525 to

535 psig (36.1 to 36.8 bar) in response to varying

demands from system service line. The control

pressure regulator valve has an orifice, which vents

a small amount of air to the atmosphere when the

Summary of Contents for LS-20T

Page 6: ......

Page 20: ...Section 2 DESCRIPTION 14 Figure 2 4A Control System Diagram Functional Components...

Page 21: ...Section 2 DESCRIPTION 15 Figure 2 4B Control System Diagram START...

Page 22: ...Section 2 DESCRIPTION 16 Figure 2 4C Control System Diagram MODULATION...

Page 23: ...Section 2 DESCRIPTION 17 Figure 2 4D Control System Diagram FULL LOAD...

Page 24: ...Section 2 DESCRIPTION 18 Figure 2 4E Control System Diagram UNLOAD...

Page 26: ...NOTES 20...

Page 30: ...NOTES 24...

Page 34: ...NOTES 28...

Page 42: ...NOTES 36...

Page 46: ...NOTES 40...

Page 49: ...NOTES 43...

Page 50: ...Section 9 ILLUSTRATIONS AND PARTS LIST 44 02250137 909R00 9 3 MOTOR FRAME COMPRESSOR AND PARTS...

Page 52: ...Section 9 ILLUSTRATIONS AND PARTS LIST 46 02250137 907R03 9 4 AIR INLET SYSTEM...

Page 54: ...Section 9 ILLUSTRATIONS AND PARTS LIST 48 02250137 907R03 9 4 AIR INLET SYSTEM...

Page 56: ...Section 9 ILLUSTRATIONS AND PARTS LIST 50 02250138 702R00 9 5 AIR INLET SUB ASSEMBLY...

Page 58: ...Section 9 ILLUSTRATIONS AND PARTS LIST 52 02250137 908R00 9 6 WATER COOLING SYSTEM...

Page 60: ...Section 9 ILLUSTRATIONS AND PARTS LIST 54 02250137 910R01 9 7 AIR PIPING SYTEM...

Page 62: ...Section 9 ILLUSTRATIONS AND PARTS LIST 56 02250137 912R01 9 8 FLUID PIPING SYSTEM...

Page 64: ...Section 9 ILLUSTRATIONS AND PARTS LIST 58 02250139 798R00 9 9 WATER PIPING SYSTEM...

Page 66: ...Section 9 ILLUSTRATIONS AND PARTS LIST 60 02250137 911R01 9 10 DISCHARGE SYSTEM...

Page 68: ...Section 9 ILLUSTRATIONS AND PARTS LIST 62 02250137 911R01 9 10 DISCHARGE SYSTEM...

Page 70: ...Section 9 ILLUSTRATIONS AND PARTS LIST 64 02250137 911R01 9 10 DISCHARGE SYSTEM...

Page 72: ...Section 9 ILLUSTRATIONS AND PARTS LIST 66 02250137 914R02 9 11 CONTROL START SYSTEM...

Page 74: ...Section 9 ILLUSTRATIONS AND PARTS LIST 68 02250137 914R02 9 11 CONTROL START SYSTEM...

Page 76: ...Section 9 ILLUSTRATIONS AND PARTS LIST 70 9 12 CONTROL PANEL 02250138 633R00...

Page 78: ...Section 9 ILLUSTRATIONS AND PARTS LIST 72 9 13 ENCLOSURE 02250138 672R00...

Page 80: ...Section 9 ILLUSTRATIONS AND PARTS LIST 74 9 13 ENCLOSURE 02250138 672R00...

Page 82: ...Section 9 ILLUSTRATIONS AND PARTS LIST 76 9 14 DECAL GROUP...

Page 84: ...Section 9 ILLUSTRATIONS AND PARTS LIST 78 9 14 DECAL GROUP...

Page 86: ...Section 9 ILLUSTRATIONS AND PARTS LIST 80 9 14 DECAL GROUP...

Page 88: ...Section 9 ILLUSTRATIONS AND PARTS LIST 82 9 15 DECAL LOCATION OPEN MODEL...

Page 90: ...Section 9 ILLUSTRATIONS AND PARTS LIST 84 9 16 DECAL LOCATION ENCLOSED MODEL...

Page 92: ...Section 9 ILLUSTRATIONS AND PARTS LIST 86 9 17 DECAL LOCATION CONTROL BOX...

Page 94: ...Section 9 ILLUSTRATIONS AND PARTS LIST 88 9 18 WIRING DIAGRAM LS20T 525 PSIG 02250137 917R01...

Page 95: ...NOTES 89...