Section 6

OPERATION

27

6.1 GENERAL

While Sullair has built into this compressor a com-

prehensive array of controls and indicators to

assure you that it is operating properly, you will

want to recognize and interpret the reading which

will call for service or indicate the beginning of a

malfunction. Before starting your Sullair compres-

sor, read this section thoroughly and familiarize

yourself with the controls and indicators - their pur-

pose, location and use.

CONTINUED...

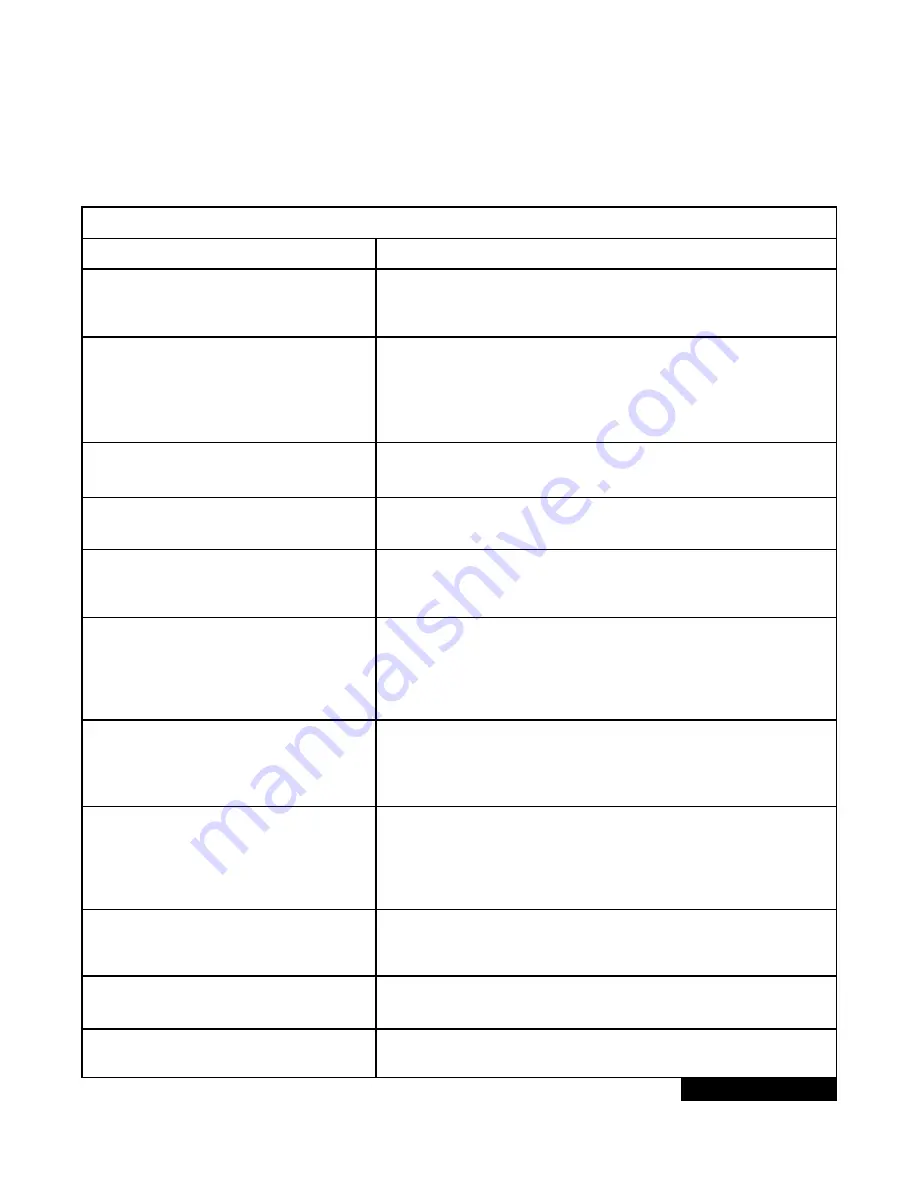

6.2 PURPOSE OF CONTROLS

CONTROL OR INDICATION

PURPOSE

FLUID LEVEL SIGHT GLASS

Monitors fluid level in the sump. Proper level should fill the sight

glass. Check level when the compressor is shut down. DO NOT

OVERFILL.

SEPARATOR RETURN LINE SIGHT

GLASS

Used to indicate fluid flow in the return lines. When the compres-

sor is running at full load, fluid flow should be visible in this sight

glass. There may b little or no flow when the compressor is run-

ning unloaded, but a sluggish flow at full load indicates a need to

clean the return line strainer.

FLUID STOP VALVE

Cuts off flow of fluid to compressor unit at compressor shutdown

and allows flow of fluid to the unit on startup.

DISCHARGE CHECK VALVE

Cuts off the reverse flow of air/fluid mixture through compressor

discharge system at compressor shutdown.

THERMAL VALVE

Regulates flow of fluid to and around the cooler. Designed to

maintain a minimum operating temperature of 220ºF (104ºC).

Also used for fast warm-up on startup.

MINIMUM PRESSURE/CHECK

VALVE

Maintains minimum of 160 psig (11 bar) in the compressor sump.

Valve piston restricts receiver air discharge from receiver/sump

when pressure falls to 160 psig (11 bar). Prevents line pressure

backflow into the sump during unload conditions and after shut-

down.

PRESSURE RELIEF VALVE (SUMP)

Opens sump pressure to the atmosphere should pressure inside

the sump becomes too high (400 psig [27.6 bar]). Operation of

this valve indicates that the high pressure transducer is either

faulty or out of adjustment.

PRESSURE RELIEF VALVE (INTER-

STAGE)

Opens interstage of compressor to atmosphere should the pres-

sure become too high (150 psig [10.3 bar]). Operation of this

valve indicates unit pressurization during shutdown. Causes may

be plugged control lines, faulty discharge check

valve, or faulty fluid stop valve.

INLET POPPET VALVE

Regulates the amount of air allowed to enter the inlet. This regu-

lation is determined by the amount of air being used at the service

line.

PRESSURE REGULATOR (INLET

POPPET VALVE)

Opens a pressure line between the sump and inlet poppet valve

allowing to regulate air delivery according to the air demand.

PRESSURE REGULATOR

(UNLOAD)

Opens a pressure line between the sump and the inlet poppet

valve to regulate the unload pressure.

Summary of Contents for LS20T 1100 CFM

Page 18: ...Section 2 DESCRIPTION 12 Figure 2 3B Control System Diagram START...

Page 19: ...Section 2 DESCRIPTION 13 Figure 2 3C Control System Diagram MODULATION...

Page 20: ...Section 2 DESCRIPTION 14 Figure 2 3D Control System Diagram FULL LOAD...

Page 21: ...Section 2 DESCRIPTION 15 Figure 2 3E Control System Diagram UNLOAD...

Page 44: ...NOTES 38...

Page 104: ...Section 9 ILLUSTRATIONS AND PARTS LIST 98 02250146 367R00 9 19 CONTROL START SYSTEM...

Page 106: ...Section 9 ILLUSTRATIONS AND PARTS LIST 100 02250146 367R00 9 19 CONTROL START SYSTEM...

Page 108: ...Section 9 ILLUSTRATIONS AND PARTS LIST 102 02250138 633R00 9 20 CONTROL PANEL...

Page 110: ...Section 9 ILLUSTRATIONS AND PARTS LIST 104 02250139 119R01 9 21 ENCLOSURE...

Page 112: ...Section 9 ILLUSTRATIONS AND PARTS LIST 106 02250139 119R01 9 21 ENCLOSURE...

Page 114: ...Section 9 ILLUSTRATIONS AND PARTS LIST 108 9 22 DECAL GROUP...

Page 116: ...Section 9 ILLUSTRATIONS AND PARTS LIST 110 9 22 DECAL GROUP...

Page 118: ...Section 9 ILLUSTRATIONS AND PARTS LIST 112 9 22 DECAL GROUP...

Page 120: ...Section 9 ILLUSTRATIONS AND PARTS LIST 114 9 23 DECAL LOCATIONS OPEN AIR COOLED...

Page 122: ...Section 9 ILLUSTRATIONS AND PARTS LIST 116 9 24 DECAL LOCATIONS OPEN WATER COOLED...

Page 124: ...Section 9 ILLUSTRATIONS AND PARTS LIST 118 9 25 DECAL LOCATIONS REMOTE COOLER...

Page 126: ...Section 9 ILLUSTRATIONS AND PARTS LIST 120 9 26 DECAL LOCATIONS CONTROL BOX...

Page 128: ...Section 9 ILLUSTRATIONS AND PARTS LIST 122 9 27 ENCLOSURE DECALS...

Page 145: ...NOTES 139...