Section 7

MAINTENANCE

30

compressor-mounting bracket. When servicing this

filter, shut the compressor down, and make sure all

pressure has been released.

Use the following procedure for separator

replacement:

1. Unthread the filter canister from the head. A hex

nut is supplied on the bottom of the canister

along with the bottom portion of the canister has

a rough textured surface. Either can be used to

assist in removal of the canister.

2. Pull the canister away from the filter head. The

filter elements will be attached to the filter head.

3. Separate the element from the filter head.

4. Remove the canister seal.

5. Thoroughly clean the filter head and canister in

solvent.

6. Lubricate the new seals with the same type of

fluid used in the compressor and position each

seal in its appropriate place.

7. Carefully push the element into position under

the housing/head.

8. Replace the canister by threading back onto the

filter head.

AIR FILTER MAINTENANCE

. Air filter maintenance should

be performed when the air filter maintenance mes-

sage is displayed. The air filter is equipped with a

primary and a secondary element. As previously

stated, the Supervisor will alert you as to when the

primary element maintenance is necessary. When

removing the primary element, always check the

secondary element for visible dirt, grease/oil, or

damage. The secondary element must be changed

after every sixth primary element inspection.

DO

NOT

clean the secondary element.

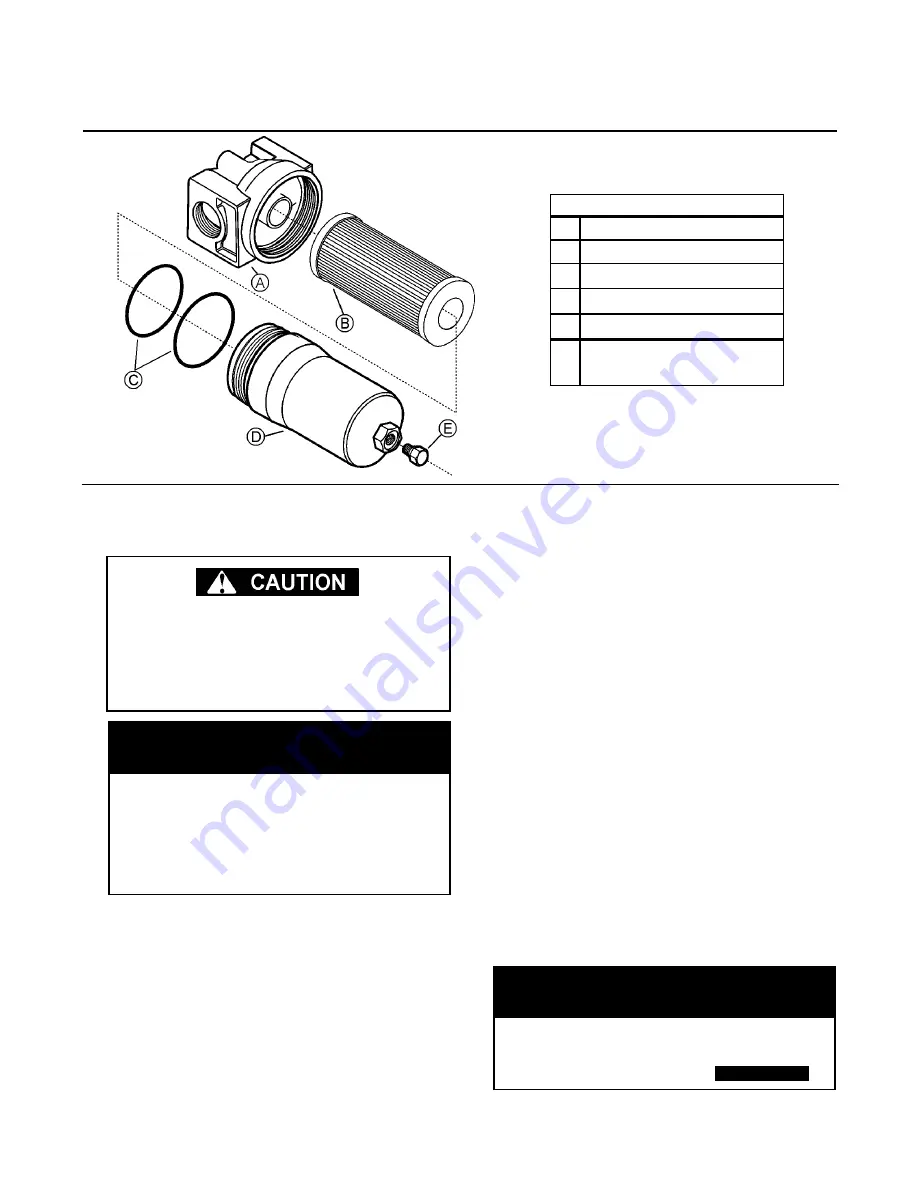

Figure 7-1 Main Filter (P/N 02250111-592)

To minimize the possibility of filter element rup-

ture, it is important that ONLY replacement ele-

ments identified with the Sullair name, logo and

appropriate part numbers be used, and that sub-

stitute elements NOT be used, due to the fact that

such filters may have inadequate or questionable

working pressure ratings.

What you may need to perform

this maintenance:

Element replacement kit no. 250031-850

Fluid Fliter wrench

Solvent cleaner and applicator (cloth,

etc.)

Machine fluid (for coating seal)

KEY

A

FILTER HEAD

B

ELEMENT*

C

SEALS*

D

BOWL

E

DRAIN PLUG

*

REPAIR KIT:

P/N 250031-850

What you may need to perform

this maintenance:

Primary replacement element no.

02250135-150

Summary of Contents for LS20T 1100 CFM

Page 18: ...Section 2 DESCRIPTION 12 Figure 2 3B Control System Diagram START...

Page 19: ...Section 2 DESCRIPTION 13 Figure 2 3C Control System Diagram MODULATION...

Page 20: ...Section 2 DESCRIPTION 14 Figure 2 3D Control System Diagram FULL LOAD...

Page 21: ...Section 2 DESCRIPTION 15 Figure 2 3E Control System Diagram UNLOAD...

Page 44: ...NOTES 38...

Page 104: ...Section 9 ILLUSTRATIONS AND PARTS LIST 98 02250146 367R00 9 19 CONTROL START SYSTEM...

Page 106: ...Section 9 ILLUSTRATIONS AND PARTS LIST 100 02250146 367R00 9 19 CONTROL START SYSTEM...

Page 108: ...Section 9 ILLUSTRATIONS AND PARTS LIST 102 02250138 633R00 9 20 CONTROL PANEL...

Page 110: ...Section 9 ILLUSTRATIONS AND PARTS LIST 104 02250139 119R01 9 21 ENCLOSURE...

Page 112: ...Section 9 ILLUSTRATIONS AND PARTS LIST 106 02250139 119R01 9 21 ENCLOSURE...

Page 114: ...Section 9 ILLUSTRATIONS AND PARTS LIST 108 9 22 DECAL GROUP...

Page 116: ...Section 9 ILLUSTRATIONS AND PARTS LIST 110 9 22 DECAL GROUP...

Page 118: ...Section 9 ILLUSTRATIONS AND PARTS LIST 112 9 22 DECAL GROUP...

Page 120: ...Section 9 ILLUSTRATIONS AND PARTS LIST 114 9 23 DECAL LOCATIONS OPEN AIR COOLED...

Page 122: ...Section 9 ILLUSTRATIONS AND PARTS LIST 116 9 24 DECAL LOCATIONS OPEN WATER COOLED...

Page 124: ...Section 9 ILLUSTRATIONS AND PARTS LIST 118 9 25 DECAL LOCATIONS REMOTE COOLER...

Page 126: ...Section 9 ILLUSTRATIONS AND PARTS LIST 120 9 26 DECAL LOCATIONS CONTROL BOX...

Page 128: ...Section 9 ILLUSTRATIONS AND PARTS LIST 122 9 27 ENCLOSURE DECALS...

Page 145: ...NOTES 139...