Section 2

11

OIL WATER SEPARATOR

INSTALLATION & MAINTENANCE

2.1

PLACE OF INSTALLATION

The OWS shall be installed on a clean, smooth and

level surface. The OWS must be installed

horizontally and should not be installed in direct

sunlight.

2.2

FLOW OF CONDENSATE

The condensate can be fed with or without pressure.

2.3

CONNECTIONS

See

.

2.4

START-UP

OWS - 88

Remove lid and filter. Fill the OWS with water until

the water runs out of the water discharge. Insert the

filter. Clean the tank and water inlet as needed. Re-

install the lid and filter, the device is now ready for

operation.

OWS - 2I0/420

Unscrew the dome. Fill the OWS with water until

water runs out of water discharge. Insert the filter.

Clean the tank and the water inlet as needed. Secure

the dome back on, the OWS is now ready for

operation.

OWS - 880-2I00

Unscrew the lid. Fill the OWS with water until water

runs out of water discharge. Insert the filter. Clean

the tank and the water inlet as needed. Secure the

dome back on, the OWS is now ready for operation.

2.5

CONDENSATE FLOW RATE

The condensation flow will depend on the

compressor and the type of oil used in the

compressor. For further information see

on page 11. The condensate must be fed

continuously. Any sporadic input of large quantities

(e.g. when emptying the tank by hand) should be

avoided.

2.6

WASTE OIL

The waste oil flows out of the tube to which an oil

drain hose will be connected, leading to an oil-

container. The

OWS-88-2I0-420

does not have an oil

discharge (oil-container). The separated oil will be

collected in the filter and will be discharged with

changing the filter.

2.7

DISCHARGING CLEAN

WATER

The clean condensate flows out through the tube

(R1") do not reduce the outlet connection.. The water

drain hose (R1” - 1”) must be connected with down

slope to the sewage system.

2.8

INSPECTIONS

A regular inspection of the running condensate and a

early change in filters (if needed) is helpful for a

flawless system. See Maintenance book provided

with your OWS.

See

for optional Level Control

instructions.

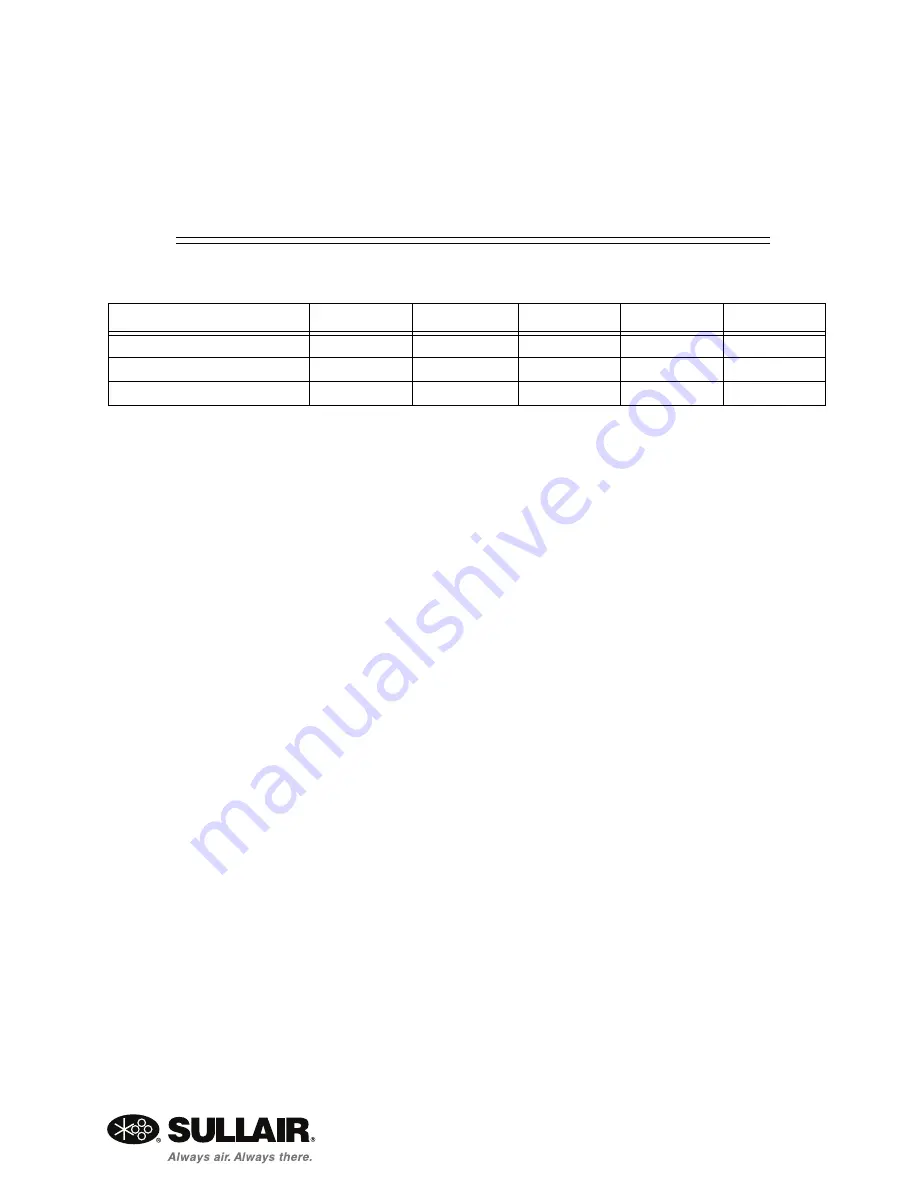

Table 2-1: CONNECTIONS

OWS-88

OWS-210/420

OWS-880

OWS1700

OWS-2100

Condensate Inlet

3 x 1/2”

4 x 1/2”

4 x 1/2”

4 x 1/2”

4 x 1/2”

Water Discharge

1 x 1”

1 x 1”

1 x 1”

1 x 1”

1 x 1”

Oil Discharge

-

-

1 x 1”

1 x 1”

1 x 1”

Summary of Contents for OWS-2I0

Page 4: ...TABLE OF CONTENTS ...

Page 6: ...OIL WATER SEPARATOR SECTION 1 6 1 1 OIL WATER SEPARATOR MODELS Figure 1 1 OWS 88 ...

Page 7: ...SECTION 1 OIL WATER SEPARATOR 7 Figure 1 2 OWS 210 ...

Page 8: ...8 NOTES Figure 1 3 OWS 420 ...

Page 9: ...SECTION 1 OIL WATER SEPARATOR 9 Figure 1 4 OWS 880 ...

Page 10: ...OIL WATER SEPARATOR SECTION 1 10 Figure 1 5 OWS 1700 2100 ...

Page 12: ...OIL WATER SEPARATOR SECTION 2 12 ...

Page 18: ...18 NOTES ...

Page 23: ...NOTES 23 ...