14

Code: 02250144

--

517 SRV

--

250 --- SRV

--

2400

English

14

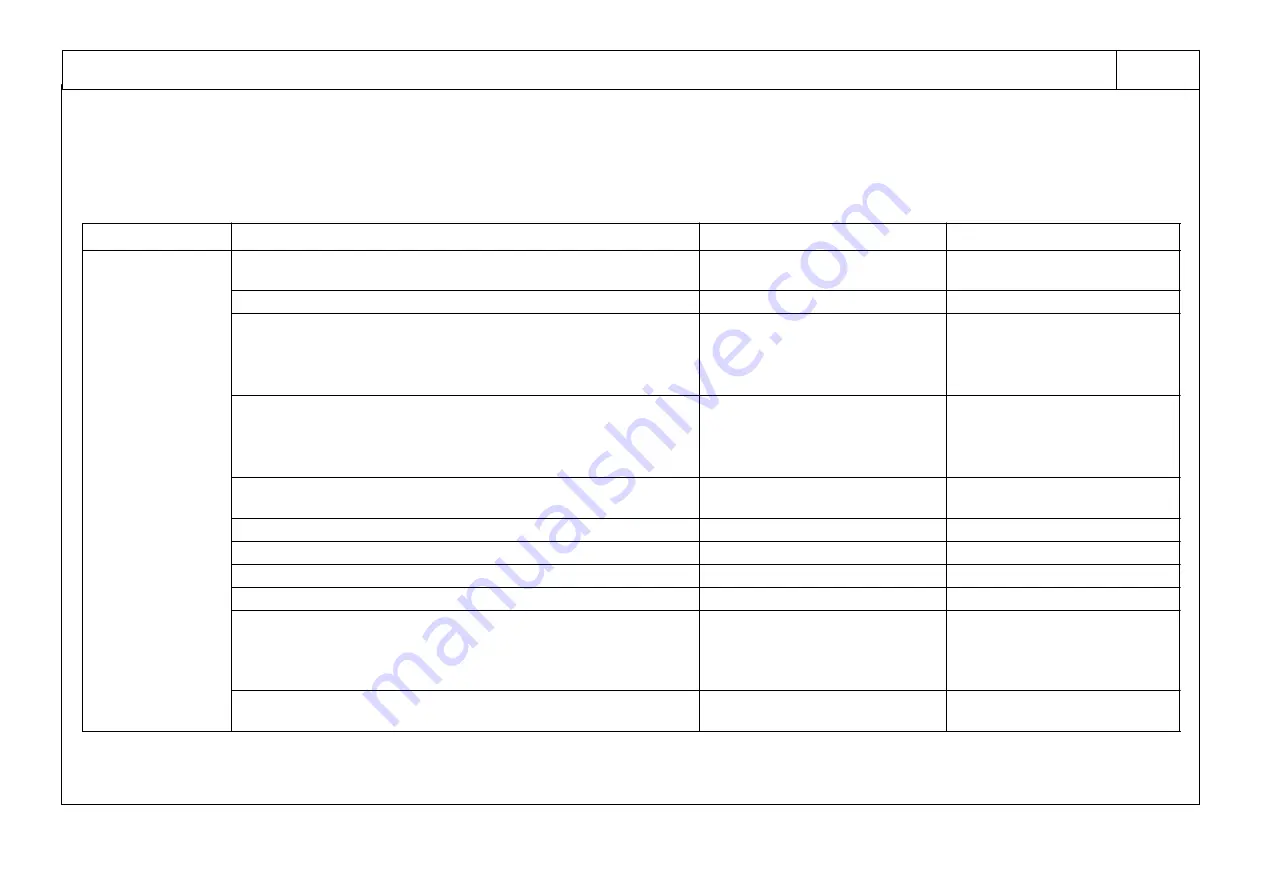

10 Trouble shooting

The following diagram lists the various problems which may occur during the dryer’s

service life. In the case of serious difficulties however, contact a refrigerant specialist.

For alarms and warnings refer also para. 6.2.

NOTE

: Always bypass the dryer when it is out of service.

Fault

Cause

Remedy

Can be simulated in test rooms

Overload (high compressed air flow and/or high inlet temperature

and/or low pressure and/or high ambient temperature).

Reduce load.

Yes, in particular for high com-

pressed air flow.

Faulty Compressor (noisy, piston valves broken, etc.).

Replace compressor.

NO

Solenoid by pass valve always open because of:

1. Wrong settings.

2. Microprocessor NO4 output always ON.

3. Dirty valve.

1. Correct settings.

2. Change microprocessor.

3. Change valve.

Yes, always ON.

Condensing pressure too high because of:

1. PV settings too high.

2. Dirty condenser surface.

3. Fan (on multi fan units) doesn’t work.

1. Change PV.

2. Clean condenser.

3. Change fan.

NO

High dew point (Hd)

Wrong Thermostatic valve setting (excessively closed or excessively

open).

Adjust setting.

Yes

Thermostatic valve broken.

Substitute valve.

NO

Wrong microprocessor settings.

Change settings.

NO

Incorrect calibration of T1, T0 and or P1.

Adjust calibrations.

YES, in particular T1 and P1.

Incorrect positioning of T0 probe.

Place in correct position.

YES

Incorrect refrigerant charge:

1. Too low (low evaporation Pressure, high superheat).

2. Too high (low discharge temperature, compressor vibration at

starts).

Re charge according to name plate

data.

YES, in particular if too low.

Thermostatic solenoid valve doesn’t work (broken or no

electrical supply).

Change valve or check and adjust

wirings.

YES