49

Code: 02250144

--

517 SRV

--

250 --- SRV

--

2400

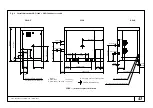

Fig. 8 Exploded drawing of dryer SRV

--

250 --- SRV

--

500 air---cooled

1. compressor

2. refrigerant condenser

3. fan motor

4. evaporator

5. separator

7. by

--

pass capillary

8. refrigerant filter

9. hot gas by

--

pass electrovalve

9a. start---up by

--

pass electrovalve

9b. thermostatic interception

electrovalve

10. air

--

air heat exchanger

11. insulation

12. fan pressure switch

14. main disconnector switch

15. high pressure switch

18. low pressure manometer

19. thermostatic valve

25. thermometer sensor pocket

27. gas charge point

29. inverter cooling fan

30. inverter automatic switch

31. fan motor contactor

33. auxiliary transformer 230V

34. auxiliary transformer 24V

35. power cable inlet

(PG 21

4

13÷18 mm)

36. remote control cable entry point

37. inductor

P1. low pressure transmitter

A1. electronic control

A2. inverter

A3. display card

A3

37