85

Code: 02250144

--

517 SRV

--

250 --- SRV

--

2400

English --

Legend

i.

ATTENTION!

Never pass compressed air through the dryer when it is stopped.

Always start the dryer 5 minutes before slowly opening the air

inlet valve. If the airflow is to bestopped only switch the dryer

off after closing the air inlet.

l.

ATTENTION:

Hot and moving parts enclosed, disconnect the

mains supply before removing this cover.

m.

WARNING:

Risk of electric shock can cause injury or death.

Disconnect all remote electric power supplies before servicing.

n.

BSPP pipe threads

use supplied adapters

o.

Air ---cooled versions:

See para. 3.2.

p.

ATTENTION

1 Fully drain the piping before connectingthis unit to theexter-

nal water piping (cold water, make up water, ect.).

2 Fitting of a standard strainer is also strongly recommended

on the inlet water piping.

q.

Water ---cooled versions:

See para. 3.2.

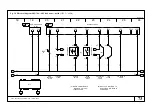

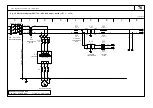

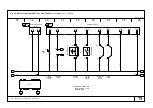

DRAWINGS

1. MC

--

1

compressor

2.

refrigerant condenser

3. EV1

fan motor

EV2

inverter fan motor

4.

evaporator

5.

separator

7.

by---pass capillary

8.

refrigerant filter

9. YV2

hot gas by

--

pass electrovalve

9a. YV1

start---up by

--

pass electrovalve

9b. YV3

thermostatic interception electrovalve

10.

air---air heat exchanger

11.

insulation

12. PV

fan pressure switch

14. QS

main disconnector switch

15. HP

high pressure switch

18.

high pressure manometer

19.

thermostatic valve

21.

distribution capillary

25.

thermometer sensor pocket

27.

gas charge point

29.

inverter cooling fan

28.

water pressostatic valve

30. QF1

inverter automatic switch

30a.QF2

fan motor automatic switch

31. KM1

fan motor contactor

33. TC1

auxiliary transformer 230V

34. TC2

auxiliary transformer 24V

35.

power cable inlet

36.

remote control cable entry point

T0

dew point temperature sensor

T1

evaporation temperature sensor

T2

refrigerant suction temperature sensor

T3

ambient temperature sensor

T4

air inlet temperature sensor

P1

low pressure transmitter

FU1

--

2 auxiliary transformer fuse

FU3

--

4 auxiliary fuse 230V

FU5

--

6 auxiliary fuse 24V

KA1

high pressure alarm relay

YV4

condensate drain valve (not installed if

electronic drain is foreseen)

A1

electronic control

A2

inverter

A3

display card

J1..J15 control connectors

QF

residual current circuit---breaker

(by installer)

LABELS

a.

S

Model

S

Serial No.

S

Low/High side refrigeration

circuit design pressure

S

Max air pressure

S

Max compressed air inlet

S

Min. ambient

Max ambient

S

Power supply

Electrical diagram no.

S

Oil

S

Min. circuit ampacity

S

Max protective device rating

S

Compressor

S

Fan 1

S

Fan 2

S

Max cooling water pressure

S

Min. cooling water pressure

S

Refrigerant

S

Weight

b. QUALITY CHECKED INSPECTOR N. 302

c. See Chapter 2

d. Air inlet

e. Air outlet

d1. Water inlet

e1. Water outlet

f.

ATTENTION:

components under power.

g.

ATTENTION: SCHRADER VALVE

1 This unit is equipped with refrigerant as for quantity and kind clearly shown

in operating manual and with identification label.

2 Any ordinary test and / or refrigerant recharge by means of connections can

take place only after refrigerant evacuation. The evacuation must be pro-

portional to dimensions and length of the connections used. The use of the

valve can be justified only when the dryer is not in working order.

3 During the unit guarantee period, the Schrader valve can be used by autho-

rized staff only, otherwise any damage caused by a wrong refrigerant

recharge will not be under warranty.

h. Condensate drain connection