Section 7

MAINTENANCE

50

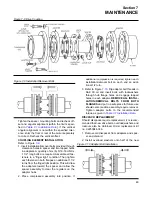

drive bolts provided, and dip threads of ALL

drive bolts with overload washers in SAE 30 or

equivalent oil. Insert drive bolts with overload

washers through alternate holes in each disc-

pack and through the small holes in each end of

the spacer, and install nuts until bolts protrude

through nut.

DO NOT FULLY TIGHTEN

.

3. Insert the remaining drive bolts from the counter-

bore side of each adapter through the three

small non-threaded holes, and through through

the remaining holes in each discpack. These

bolts should now be protruding through the large

holes in each flange of the spacer. Install the

remaining overload washers and nuts onto

these bolts. All nuts should be on the spacer

side and all bolts heads located in the adapter.

. Tightening of all drive bolts

should be done with the center component

assembly in a horizontal position. The most reli-

able method of tightening drive bolts is achieved

using Drive Bolt Elongation. Measure the length

of the #1 drive bolt with an outside micrometer

and record. Hold the drive bolt head and tighten

the nut to the tightening torque listed in

Subtract the first reading from the second read-

ing. Compare the difference to the elongation

listed in

increase or decrease tightening to achieve prop-

er elongation. Repeat this procedure for each

drive bolt in cylinder head fashion illustrated in

Figure

.

SHRINK DISC INSTALLATION

supplied ready for installation. Therefore, they

should not be disassembled prior to initial installa-

tion.

INSTALLATION SEQUENCE

1. Remove spacers placed between collars for pro-

tection during transportation.

2. Take any three locking screws forming the points

of an equilateral triangle (e.g. screw 1, 5 and 9

in Figure

) and tighten them slightly until the

inner ring can still just be turned.

3. Slide shrink disc over the hub. The hub outside

surface can be greased.

Never tighten locking screws before shaft is inside

the hub.

4. Degrease the hub bore and shaft seat.

5. Insert shaft or slide hub over the shaft.

6. Refer to Figure

. Tighten all locking screws

gradually and all the way around (not in diamet-

rically opposite sequence).

Several passes are required until all screws are

torqued to specified tightening torque of 42 ft.-lbs.

(57 Nm). Check tightening torque (42 ft.-lbs. [57

Nm]) with a torque wrench. Both collars must

remain an equal distance apart.

REMOVAL

Shrink disc removal procedure is similar to installa-

tion.

Figure 7-11 Drive Bolt Tightening Pattern

Figure 7-12 Bolt Tightening

Figure 7-13 Hub Cutaway

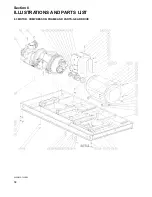

Summary of Contents for TS-32S

Page 16: ...Section 2 DESCRIPTION 10 Figure 2 3A Compressor Cooling and Lubrication System Air cooled...

Page 17: ...Section 2 DESCRIPTION 11 Figure 2 3B Compressor Cooling and Lubrication System Water cooled...

Page 18: ...Section 2 DESCRIPTION 12 Figure 2 4A Compressor Discharge System Air cooled...

Page 19: ...Section 2 DESCRIPTION 13 Figure 2 4B Compressor Discharge System Water cooled...

Page 20: ...Section 2 DESCRIPTION 14 Figure 2 5A Control System START Typical...

Page 21: ...Section 2 DESCRIPTION 15 Figure 2 5B Control System MODULATION Typical...

Page 22: ...Section 2 DESCRIPTION 16 Figure 2 5C Control System UNLOAD Typical...

Page 23: ...Section 2 DESCRIPTION 17 Figure 2 5D Control System FULL LOAD Typical...

Page 27: ...Section 3 SPECIFICATIONS 21 NOTES...

Page 40: ...34 NOTES...

Page 48: ...42 NOTES...

Page 60: ...54 NOTES...

Page 63: ...57 NOTES...

Page 72: ...Section 8 ILLUSTRATIONS AND PARTS LIST 66 8 5 AIR INLET SYSTEM 02250135 499R01...

Page 114: ...Section 8 ILLUSTRATIONS AND PARTS LIST 108 02250135 534R03 8 20 SUMP AND PARTS...

Page 116: ...Section 8 ILLUSTRATIONS AND PARTS LIST 110 02250135 534R03 8 20 SUMP AND PARTS...

Page 118: ...Section 8 ILLUSTRATIONS AND PARTS LIST 112 02250134 158R00 8 21 SULLICON CONTROL...

Page 120: ...Section 8 ILLUSTRATIONS AND PARTS LIST 114 8 22 COMPRESSOR SPIRIAL VALVE ACTUATOR...

Page 124: ...Section 8 ILLUSTRATIONS AND PARTS LIST 118 02250135 643R05 8 24 PNEUMATIC CONTROLS...

Page 126: ...Section 8 ILLUSTRATIONS AND PARTS LIST 120 02250135 643R05 8 24 PNEUMATIC CONTROLS...

Page 128: ...Section 8 ILLUSTRATIONS AND PARTS LIST 122 02250135 643R05 8 24 PNEUMATIC CONTROLS...

Page 134: ...Section 8 ILLUSTRATIONS AND PARTS LIST 128 8 27 CONTROL BOX WYE DELTA TYPICAL 02250122 516R08...

Page 140: ...Section 8 ILLUSTRATIONS AND PARTS LIST 134 02250133 674R04 8 30 ENCLOSURE AIR COOLED...

Page 142: ...Section 8 ILLUSTRATIONS AND PARTS LIST 136 02250133 674R04 8 30 ENCLOSURE AIR COOLED...

Page 144: ...Section 8 ILLUSTRATIONS AND PARTS LIST 138 02250133 675R04 8 31 ENCLOSURE WATER COOLED...

Page 146: ...Section 8 ILLUSTRATIONS AND PARTS LIST 140 02250133 675R04 8 31 ENCLOSURE WATER COOLED...

Page 148: ...Section 8 ILLUSTRATIONS AND PARTS LIST 142 8 32 DECALS...

Page 150: ...Section 8 ILLUSTRATIONS AND PARTS LIST 144 8 32 DECALS...

Page 152: ...Section 8 ILLUSTRATIONS AND PARTS LIST 146 8 32 DECALS...

Page 154: ...Section 8 ILLUSTRATIONS AND PARTS LIST 148 8 33 DECAL LOCATIONS...

Page 156: ...Section 8 ILLUSTRATIONS AND PARTS LIST 150 8 34 DECAL LOCATIONS AIR COOLED ENCLOSURE TYPICAL...

Page 158: ...Section 8 ILLUSTRATIONS AND PARTS LIST 152 8 35 DECAL LOCATIONS WATER COOLED ENCLOSURE TYPICAL...

Page 160: ...Section 8 ILLUSTRATIONS AND PARTS LIST 154 8 36 DECAL LOCATIONS CONTROL BOX...

Page 162: ...Section 8 ILLUSTRATIONS AND PARTS LIST 156 8 37 DECAL LOCATIONS AFTER COOLER...

Page 171: ...NOTES...