Section 7

MAINTENANCE

51

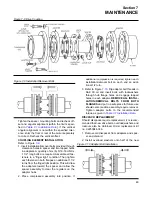

1. Gradual release of locking screws all the way

around. Initially each screw should be released

about a quarter of a turn only. Thus tilting and

jamming of collars will be avoided.

DO NOT

remove locking screws.

2. Remove shaft or pull hub from the shaft. Any rust

formed on shaft in front of hub must first be

removed.

3. Pull shrink disc from hub.

CLEANING AND LUBRICATION

Removed shrink discs need not to be taken apart or

lubricated prior to reinstallation. Only a dirty shrink

disc should be cleaned and lubricated.

For the tapered surfaces, use one of the lubricant

recommendations shown in

7.8 TROUBLESHOOTING

The information contained in the Troubleshooting

chart is based upon both the actual applied situa-

tions and extensive testing at the factory. It contains

symptoms and usual causes for the described prob-

lems. However

DO NOT

assume that these are the

only problems that may occur. All available data

concerning the trouble should be systematically

analyzed before undertaking any repair or compo-

nent replacement.

A detailed visual inspection is worth performing for

almost any problems which may prevent unneces-

sary damage to the compressor. Always remember

to:

a. Check for loose wiring.

b. Check for damaged piping.

c. Check for parts damaged by heat or an electrical

short circuit, usually apparent by discoloration or

a burnt odor.

Should your problem persist after making the rec-

ommended check, consult your nearest Sullair rep-

resentative or the Sullair Corporation.

LUBRICANT (MoS2)

TYPE

Molykote 321 R

Spray

(lube coat)

Molykote Spray

Spray

(powder spray)

Molykote G Rapid

Spray or Paste

Aemason MO 19 P

Spray or Paste

DIO-setral 57 N

(lube coat)

Spray or Paste

Locking screws are lubricated with a multipurpose

grease as Molykote BR 2 or similar.

Table 7-2 Tapered Surface Lubricants

COMPRESSOR WILL NOT START

COMPRESSOR SHUTS DOWN

WITH AIR DEMAND PRESENT

Main Disconnect Switch Open

Line Fuse Blown

Control Transformer Fuse Blown

Motor Starter Overloads Tripped

Low Incoming Line Voltage

Loss of Control Voltage

Low Incoming Voltage

Close switch.

Replace fuse.

Replace fuse.

Reset. Should trouble persist, check whether

motor starter contacts are functioning properly.

Check voltage. Should voltage check low, consult

power company.

Replace Supervisor display module if no display

or erratic display.

Check incoming power.

Check control fuses and wiring.

Consult power company. The Sullair Supervisor

will provide indication of most maintenance prob-

lems if control power has not been lost. Shutdowns

will occur upon a faulty condition or a bad sender

condition.

7.9 TROUBLESHOOTING GUIDE (I)

SYMPTOM

PROBABLE CAUSE

REMEDY

(I)

Consult the Supervisor Controller manual for additional aid to troubleshooting.

Summary of Contents for TS-32S

Page 16: ...Section 2 DESCRIPTION 10 Figure 2 3A Compressor Cooling and Lubrication System Air cooled...

Page 17: ...Section 2 DESCRIPTION 11 Figure 2 3B Compressor Cooling and Lubrication System Water cooled...

Page 18: ...Section 2 DESCRIPTION 12 Figure 2 4A Compressor Discharge System Air cooled...

Page 19: ...Section 2 DESCRIPTION 13 Figure 2 4B Compressor Discharge System Water cooled...

Page 20: ...Section 2 DESCRIPTION 14 Figure 2 5A Control System START Typical...

Page 21: ...Section 2 DESCRIPTION 15 Figure 2 5B Control System MODULATION Typical...

Page 22: ...Section 2 DESCRIPTION 16 Figure 2 5C Control System UNLOAD Typical...

Page 23: ...Section 2 DESCRIPTION 17 Figure 2 5D Control System FULL LOAD Typical...

Page 27: ...Section 3 SPECIFICATIONS 21 NOTES...

Page 40: ...34 NOTES...

Page 48: ...42 NOTES...

Page 60: ...54 NOTES...

Page 63: ...57 NOTES...

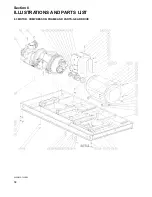

Page 72: ...Section 8 ILLUSTRATIONS AND PARTS LIST 66 8 5 AIR INLET SYSTEM 02250135 499R01...

Page 114: ...Section 8 ILLUSTRATIONS AND PARTS LIST 108 02250135 534R03 8 20 SUMP AND PARTS...

Page 116: ...Section 8 ILLUSTRATIONS AND PARTS LIST 110 02250135 534R03 8 20 SUMP AND PARTS...

Page 118: ...Section 8 ILLUSTRATIONS AND PARTS LIST 112 02250134 158R00 8 21 SULLICON CONTROL...

Page 120: ...Section 8 ILLUSTRATIONS AND PARTS LIST 114 8 22 COMPRESSOR SPIRIAL VALVE ACTUATOR...

Page 124: ...Section 8 ILLUSTRATIONS AND PARTS LIST 118 02250135 643R05 8 24 PNEUMATIC CONTROLS...

Page 126: ...Section 8 ILLUSTRATIONS AND PARTS LIST 120 02250135 643R05 8 24 PNEUMATIC CONTROLS...

Page 128: ...Section 8 ILLUSTRATIONS AND PARTS LIST 122 02250135 643R05 8 24 PNEUMATIC CONTROLS...

Page 134: ...Section 8 ILLUSTRATIONS AND PARTS LIST 128 8 27 CONTROL BOX WYE DELTA TYPICAL 02250122 516R08...

Page 140: ...Section 8 ILLUSTRATIONS AND PARTS LIST 134 02250133 674R04 8 30 ENCLOSURE AIR COOLED...

Page 142: ...Section 8 ILLUSTRATIONS AND PARTS LIST 136 02250133 674R04 8 30 ENCLOSURE AIR COOLED...

Page 144: ...Section 8 ILLUSTRATIONS AND PARTS LIST 138 02250133 675R04 8 31 ENCLOSURE WATER COOLED...

Page 146: ...Section 8 ILLUSTRATIONS AND PARTS LIST 140 02250133 675R04 8 31 ENCLOSURE WATER COOLED...

Page 148: ...Section 8 ILLUSTRATIONS AND PARTS LIST 142 8 32 DECALS...

Page 150: ...Section 8 ILLUSTRATIONS AND PARTS LIST 144 8 32 DECALS...

Page 152: ...Section 8 ILLUSTRATIONS AND PARTS LIST 146 8 32 DECALS...

Page 154: ...Section 8 ILLUSTRATIONS AND PARTS LIST 148 8 33 DECAL LOCATIONS...

Page 156: ...Section 8 ILLUSTRATIONS AND PARTS LIST 150 8 34 DECAL LOCATIONS AIR COOLED ENCLOSURE TYPICAL...

Page 158: ...Section 8 ILLUSTRATIONS AND PARTS LIST 152 8 35 DECAL LOCATIONS WATER COOLED ENCLOSURE TYPICAL...

Page 160: ...Section 8 ILLUSTRATIONS AND PARTS LIST 154 8 36 DECAL LOCATIONS CONTROL BOX...

Page 162: ...Section 8 ILLUSTRATIONS AND PARTS LIST 156 8 37 DECAL LOCATIONS AFTER COOLER...

Page 171: ...NOTES...