SECTION 3

TS32 USER MANUAL

53

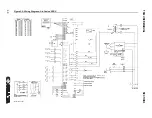

Figure 3-10: Wiring Diagram—Remote Air-Cooled Wye Delta

COMP

DESCRIPTION

1M

COMPRESSOR MOTOR STARTER

1MOL

COMPRESSOR MOTOR STARTER OVERLOAD CONTACT

2M

COMPRESSOR MOTOR STARTER RUN CONTACTOR

S

COMPRESSOR START CONTACTOR

3M

FAN MOTOR STARTER

3MOL

FAN MOTOR STARTER OVERLOAD CONTACT

4M

CANOPY FAN STARTER (OPT'L)

4MOL

CANOPY FAN MOTOR STARTER OVERLOAD CONTACT

5MOL

SECOND CANOPY FAN MOTOR OVERLOAD

6M

OPTIONAL CONTACTOR FOR PF CAPACITOR

1FU

TRANSFORMER PRIMARY FUSES

2FU

TRANSFORMER SECONDARY FUSE

3FU

COOLER FAN BRANCH FUSES

4FU

CANOPY FAN BRANCH FUSES

P1

WET SUMP PRESSURE SENSOR - SET PER FACE OF

ORDER

P2

PACKAGE DISCHARGE PRESSURE SENSOR

P3

OIL FILTER DISCHARGE PRESSURE SENSOR

P4

OIL FILTER UPSTREAM PRESSURE SENSOR

T1

UNIT DISCHAGE TEMPERATURE RTD

T2

DRY DISCHARGE TEMPERATURE RTD

T3

INJECTION OIL TEMPERATURE RTD

T4

INTERSTAGE TEMPERATURE RTD

DPSW1

OIL FILTER DIFFERENTIAL PRESSURE SWITCH (OPT'L)

PSW1

INLET AIR FILTER SWITCH: 22 IN WC (558.9 MM WC)

SOL1

LOAD CONTROL SOLENOID VALVE

SOL2

SPIRAL CONTROL SOLENOID VALVE (OPTIONAL)

SOL3

START CONTROL SOLENOID VALVE

SOL4

SEQUENCING/FULL LOAD SOLENOID VALVE (OPTIONAL)

SOL5

COMBO DRAIN/JZL DRAIN SOLENOID VALVE

1XFMR

CONTROL VOLTAGE TRANSFORMER

2XFMR

SUPERVISOR 3 STEPDOWN TRANSFORMER 24VAC

K1

INTERNAL RUN RELAY CONTACT

K2

INTERNAL Y-DELTA RELAY CONTACT

K3

INTERNAL LOAD CONTROL RELAY CONTACT

K4

INTERNAL SEQUENCE RELAY CONTACT

K5

INTERNAL ELECTRIC DRAIN RELAY CONTACT

K6

INTERNAL COMMON FAULT RELAY CONTACT

K7

INTERNAL COMMON WARNING RELAY CONTACT

K8

INTERNAL SPECIAL FUNCTION CONTACT

PMR

OPT'L POWER MONITOR RELAY

HRN

OPT'L AUDIBLE ALARM

HTR1

SUMP HEATER

HTR2

HEAT TRACE

HTR3

TRAP HEATER

HTR4

CONTROL PANEL HEATER

TH

THERMOSTAT FOR HEAT TRACE

TSW1

OIL TEMPERATURE SWITCH

NOTES:

1. CUSTOMER TO FURNISH FUSED OR CIRCUIT BREAKER DISCON-

NECT PER LOCAL CODES.

2. REMOVE JUMPER FOR AUXILIARY E-STOP STRING DEVICES.

3. CUSTOMER WIRING REQUIRED BETWEEN COOLER MOTOR AND

MACHINE MOUNTED STARTER.

4. OPTIONAL.

5.

2ND FAN MOTOR FOR 400HP AND LARGER.

6.

BELDEN TYPE 9842 4 COND. 2 TWISTED PAIR W/SHIELD OR

EQUIVALENT. TO MATCHING TERMINALS ON NEXT COMPRESSOR.

REFER TO SUPERVISOR SEQUENCING PROTOCOL MANUAL.

COMP

DESCRIPTION

Summary of Contents for TS32 AC

Page 10: ...NOTES 10...

Page 15: ...SECTION 2 TS32 USER MANUAL 15 Figure 2 3 Compressor Piping and Instrument Diagram Typical...

Page 16: ...TS32 USER MANUAL SECTION 2 16 Figure 2 4 Compressor Cooling and Lubrication System Air cooled...

Page 18: ...TS32 USER MANUAL SECTION 2 18 Figure 2 6 Compressor Discharge System Air cooled 200 350HP...

Page 19: ...SECTION 2 TS32 USER MANUAL 19 Figure 2 7 Compressor Discharge System Water cooled 200 350HP...

Page 20: ...TS32 USER MANUAL SECTION 2 20 Figure 2 8 Control System START Typical...

Page 21: ...SECTION 2 TS32 USER MANUAL 21 Figure 2 9 Control System MODULATION Typical...

Page 22: ...TS32 USER MANUAL SECTION 2 22 Figure 2 10 Control System UNLOAD Typical...

Page 23: ...SECTION 2 TS32 USER MANUAL 23 Figure 2 11 Control System FULL LOAD Typical...

Page 26: ...TS32 USER MANUAL SECTION 2 26 Figure 2 12 Compressor Air Inlet System...

Page 30: ...TS32 USER MANUAL SECTION 3 30 Figure 3 2 Identification Air Cooled 02250126 376 R02...

Page 32: ...TS32 USER MANUAL SECTION 3 32 Figure 3 2 Identification Water Cooled 02250126 378 R03...

Page 50: ...TS32 USER MANUAL SECTION 3 50 Figure 3 9 Wiring Diagram Air Cooled SSRV 02250178 844 R03...

Page 54: ...NOTES 54...

Page 78: ...NOTES 78...

Page 79: ...NOTES 79...