ES-8 MOBILE APPLICATION MANUAL R00

SECTION 3

14

3.6

LUBRICATION GUIDE

For best value and longest uninterrupted service, the

ES-8 compressor is factory filled and tested with a

long life lubricant.

Maintenance of all other components is still

recommended as indicated in the Operator’s Manual.

For light-duty high-humidity service where

condensed moisture and emulsification

(mayonnaise) may occur, the fluid change interval

must be reduced to 300 hours maximum. A non-

detergent fluid with rust, oxidation and foam

inhibitors and good water separation characteristics

should be used.

DO NOT MIX DIFFERENT TYPES OF FLUIDS.

Contamination of non-detergent mineral fluids with

traces of ATF or detergent motor fluids may lead to

operational problems such as foaming, filter

plugging, orifice or line plugging.

When ambient conditions exceed those noted or if

conditions warrant use of “extended” life lubricants

contact Sullair for recommendation.

Sullair encourages the user to participate in a fluid

analysis program. This could result in a fluid change

interval that is different from those stated in this

manual.

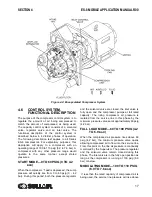

3.7

LUBRICATION CHANGE RECOMMENDATIONS & MAINTENANCE

SCHEDULE

WARNING

“The Plastic Pipe Institute recommends

against the use of thermoplastic pipe to

transport compressed air or other com-

pressed gases in exposed above ground

locations, e.g. in exposed plant piping.” (I)

Sullube 32 should not be used with PVC

piping systems. It may affect the bond at

cemented joints. Certain other plastic mate-

rials may also be affected.

(I) Plastic Pipe Institute, Recommendation

B, Adopted January 19, 1972.

NOTE

Flush system when switching lubricant

brands.

AMBIENT

TEMPERATURE

LUBRICANT

FLUID & FILTER

CHANGE PERIOD

(HRS.)

SEPARATOR CHANGES

PERIOD (HRS.)

AIR FILTER CHANGE

PERIOD (HRS.)

-10°F to +90°F

(-23°C to +32°C)

Sullube 32

8000

8000

4000 (II)

(I) 8,000 Hours or once a year

(II) 4,000 Hours or more frequently if conditions so require.

Summary of Contents for 30XH

Page 10: ...NOTES 10 ...

Page 22: ...NOTES 22 ...

Page 33: ...NOTES 33 ...

Page 34: ...INLET CONTROL SEAL DRIVE GEAR AND PARTS 34 8 3 INLET CONTROL SEAL DRIVE GEAR AND PARTS ...

Page 36: ...MOTOR COUPLING FAN AND PARTS 36 8 4 MOTOR COUPLING FAN AND PARTS ...

Page 40: ...COMPRESSOR COOLER SYSTEM AND PARTS 40 8 6 COMPRESSOR COOLER SYSTEM AND PARTS ...

Page 42: ...PNEUMATIC CONTROL SYSTEM AND PARTS 42 8 7 PNEUMATIC CONTROL SYSTEM AND PARTS ...

Page 44: ...CONTROL STARTER MFV 44 8 8 CONTROL STARTER MFV ...

Page 46: ...DECAL GROUP 46 8 9 DECAL GROUP ...

Page 48: ...DECAL GROUP 48 8 9 DECAL GROUP CONTINUED ...

Page 50: ...WIRING DIAGRAM FULL VOLTAGE STANDARD 50 8 10 WIRING DIAGRAM FULL VOLTAGE STANDARD ...

Page 51: ...NOTES 51 ...