16E / 16E-H / 16E-P Spray Gun

46

MAN 96150 EN 01

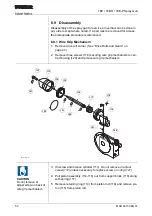

5. Carefully press nozzle (23) into front of siphon plug (20). Be care-

ful that nozzle o-rings are not twisted or torn and ensure that noz-

zle shoulder is flush with front of siphon plug.

6. Install nozzle nut (28) on siphon plug (20) and tighten firmly by

hand.

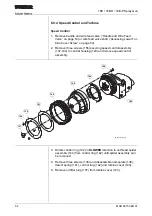

7. Carefully press siphon plug assembly (18-28) into gas head

assembly (75). Twist slightly and align cutouts in siphon plug

flange with pins on gas head assembly. You should feel each

siphon plug o-ring slip into the bore. The siphon plug is fully seated

when the gas head pins extend slightly beyond the siphon plug

flange.

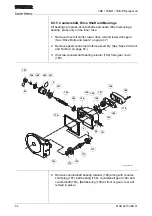

8. Install air cap (29).

9. Install air cap body (33) on gas head assembly (75) and tighten

firmly by hand.