16E / 16E-H / 16E-P Spray Gun

38

MAN 96150 EN 01

5

Troubleshooting

Where troubleshooting procedures call for disassembly, inspection,

assembly and replacement of parts, see “Maintenance” on page 41.

5.1

Avoiding Trouble

•

Most common problems are avoided by keeping the spray gun

clean and lubricated. See “General Gun Care” on page 41.

•

Inspection, cleaning, lubrication and regular maintenance will

ensure the spray gun and it’s parts remain in good working order.

See“Scheduled Maintenance” on page 44.

•

Whenever the performance of the spray gun or the quality of the

coating deteriorates, maintenance should be performed.

•

Ensure the metalizing wire is clean and in good condition. Trim any

wire that is bent, nicked or gouged before feeding it into the gun.

Most wires have a light coating of lubricant to aid in feeding

through the nozzle. Dust or dirt on the wire will accelerate wear of

the nozzle and wire guides. Always leave the original tag on the

wire spool so that the wire can be identified.

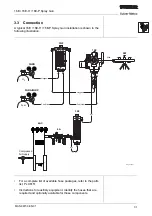

5.2

Difficult Lighting

Possible Causes:

•

Damaged or dirty nozzle and/or siphon plug

•

Damaged or loaded air cap

•

Damaged or obstructed hoses

•

Plugged valve core bleeder holes

Corrective Measures:

•

Make sure that the nozzle and siphon plug are clean and undam-

aged.

•

Turn fuel and oxygen tanks off, purge the system, screw out the

regulator handles to shut off the gases, and then disconnect the

hoses. Inspect hoses and gun fittings for dirt or other obstructions.

Blow out the hoses before reconnecting them.

•

Perform “Lighting Flow Check” on page 40.

•

If the gun has been idle for some time, or after the valve has just

been lubricated, work the valve on and off a few times with gases

and air turned on before lighting. This will blow out any excess

valve lubricant.