Página 6 de 19

CONTROL PANEL SULZER APC 1/2B

USER GUIDE

Rev.13 (2018/08/30)

When using an analogue sensor (hydrostatic, ultrasonic

…), remember to connect properly the

cable's shield to the control panel ground to avoid noises and disturbances in the measurement

signal

. Settings in PC 242 when it is mounted in an ABS APC control panel include a time filter for this

input signal, if were needed you could increase the default pre-set time filter setting.

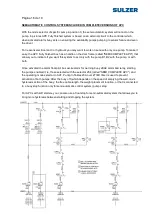

You have to consider that the

majority of

the mistakes using a pneumatic sensor

usually happen due to pipe clogging or

due to air losses in the pipe or/and pipe

junctions

; if you are going to use a pre-

fabricated sump made by ABS without this

inlet and with an APC control panel with

MD 124 pneumatic sensor, make sure to

avoid pipe clogging as making a diagonal

cut to the air pipe to have a bigger area of

the side of the pipe submersed (as it is

shown at the left side picture).

When using an hydrostatic level sensor you must

consider effects that could appear when installing

the sensor hung from the pump pit top; turbulences

could make it hit itself with the sump walls or

making a pendular movement that will could wear

sensor housing due friction; it even could be as

close to the pumps inlet that they could be able to

suck up the sensor. You have to choose the best

way to install the sensor considering the

turbulences are supposed to appear, effect of the

pump hydraulic inlets... The right side picture

shows some ways to install this kind of sensors. No

matter the way chosen,

make sure to install the

sensor avoiding the pumps were able to suck it

up, and avoiding the sensor were moving with

friction against a wall or hitting it; if not, the

sensor could be damaged till break down

.