11

6

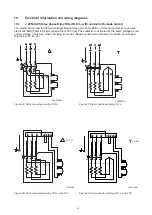

Change of mechanical seal unit on J 205, J 405 / Mechanical seals J 604

Dismantling

Clean the shaft end.

J 205 - J 405:

Unscrew the screws holding the me-

chanical seal unit. Use the same screws in the alterna-

tive holes on the seal unit to carefully pull the seal unit

out from the shaft. Check that there are no burrs on the

shaft. If wear plate must be replaced, continue on com-

plete pump overhaul 7.1. (Figure 11)

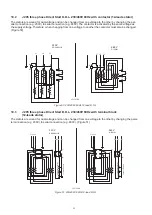

J 604:

Release pressure on spring and lift off rotating

part of primary seal. Note that he stationary ring is still

in the oil casing cover. Unscrew inner and outer nuts

that secures both the rubberized wear plate and the oil

casing cover and remove them. Dismantle the station-

ary ring of the primary seal from the oil casing cover.

Remove circlip under the secondary seal. Pull out rotat-

ing part on secondary seal. Remove the stationary ring

from the oil casing. (Figure 12)

Assembly

J 205 - J 405:

Grease the shaft end. Mount the me-

chanical seal unit carefully with new and well greased

o-rings and tighten it firmly with screws.

J 604:

Mount the secondary seal, first the stationary

ring on the oil casing and then the rotating ring and

circlip, by using the special tool. Mount the oil casing

cover and then put the primary seal stationary ring in

place and fix it with the retaining ring (pos 82 + 85 in

spare part list). Push on the rotating part of the primary

seal by using a special tool, see section special tools.

Mount the rubberized wear plate and tighten inner and

outer nuts.

For assembly of pump proceed directly to section 9.

Note!

Never run the motor without having the impeller mount

-

ed. This can cause damage to o-rings in seal.

Figure 11: Dismantling mechanical seal unit (J 205, J 405)

Figure 12: Dismantling mechanical seals (J 604)

Summary of Contents for J 205

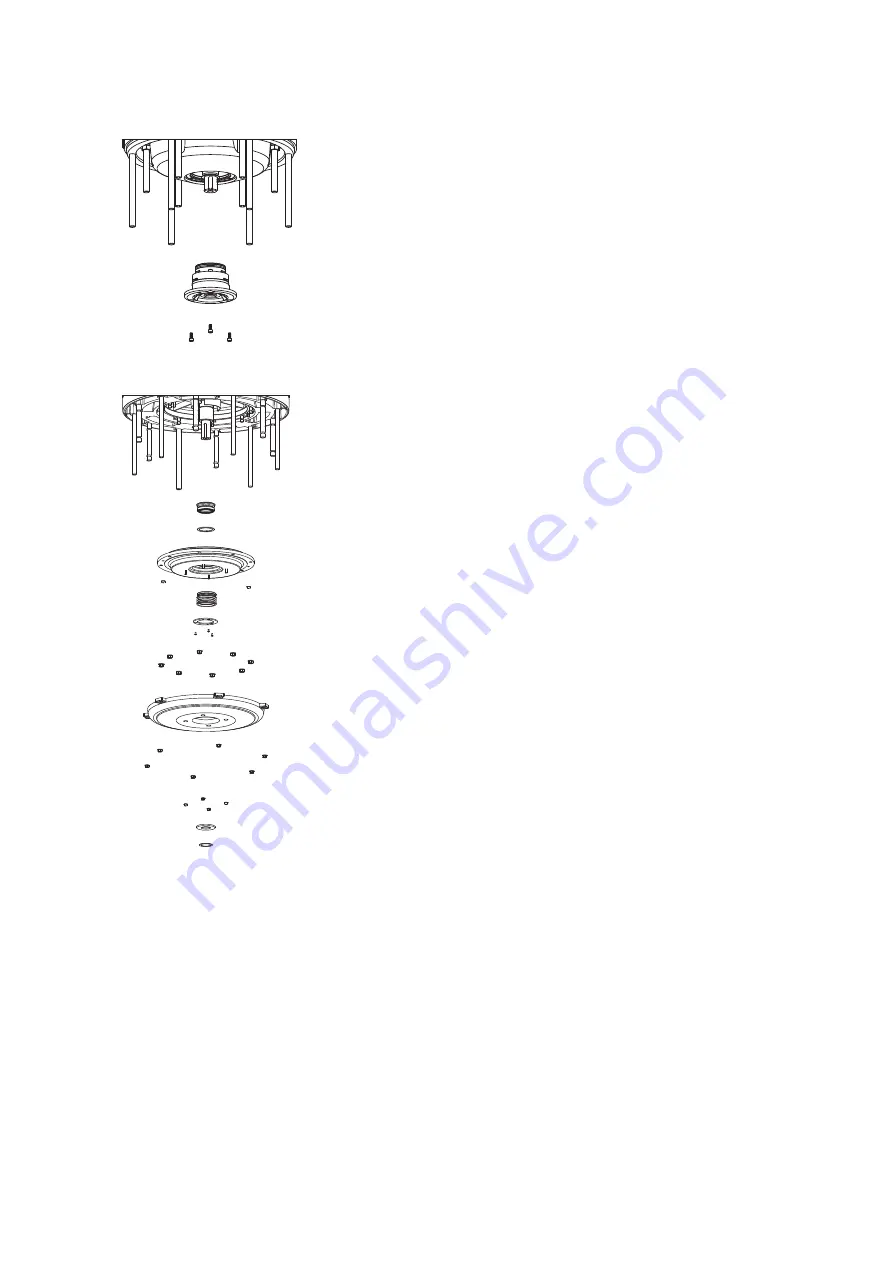

Page 30: ...30 11 Sectional drawing Tools J 205 ...

Page 31: ...31 J 405 ...

Page 32: ...32 J 604 ...

Page 37: ...37 ...