12

7

Complete pump overhaul / Dismantling

Dismantle the pump as described in the sections 2-6.

Note!

Oil drainage, mechanical seal and wear plate disman-

tling can wait until cooling jacket is removed.

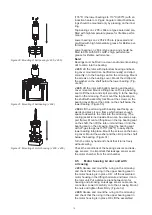

7.1

Electrical supply leads

Disconnect all electrical leads from the terminal board /

contactor in the pump. Then start to remove power and

control cables from the pump. (Figure 13)

J 205:

The power and control cable are incorporated

in the top cover and will be removed when cables are

disconnected from the terminal board /contactor. Re-

move cable clamps prior to unscrewing cable gland

from cover. Pull out cables.

J 405:

Remove cable clamps prior to unscrewing cable

gland from upper motor part. Unscrew cable gland and

pull the cable out together with the cable gland.

J 604:

Remove cable clamps prior to unscrewing nuts

that hold the cable gland and pull the cable together

with the cable gland out.

Check the condition of the cable, cable seals and cable

glands when cover is removed. When a cable seal is

removed always replace it with a new.

7.2

Discharge connection

Unscrew the nuts that hold the discharge elbow and

remove it. (J 604 has a clamping ring holding the dis-

charge connection.) (Figure 13)

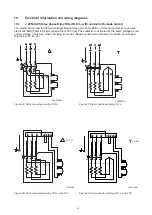

7.3

Cooling jacket

Make sure all inspection plugs are removed from the

cooling jacket prior to dismantling cooling jacket.

J 205:

Lift the pump up in the handle into a vertical

position with a lifting device and secure it. Put the pump

standing on the outer longer stud bolts. Place a dis-

tance piece under the diffuser stud bolts (preferably a

wooden frame at a diameter of the diffuser stud bolts).

Loosen the stud bolts holding the cooling jacket and lift

off the cooling jacket from the motor housing. (Figure

14)

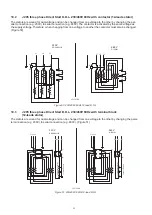

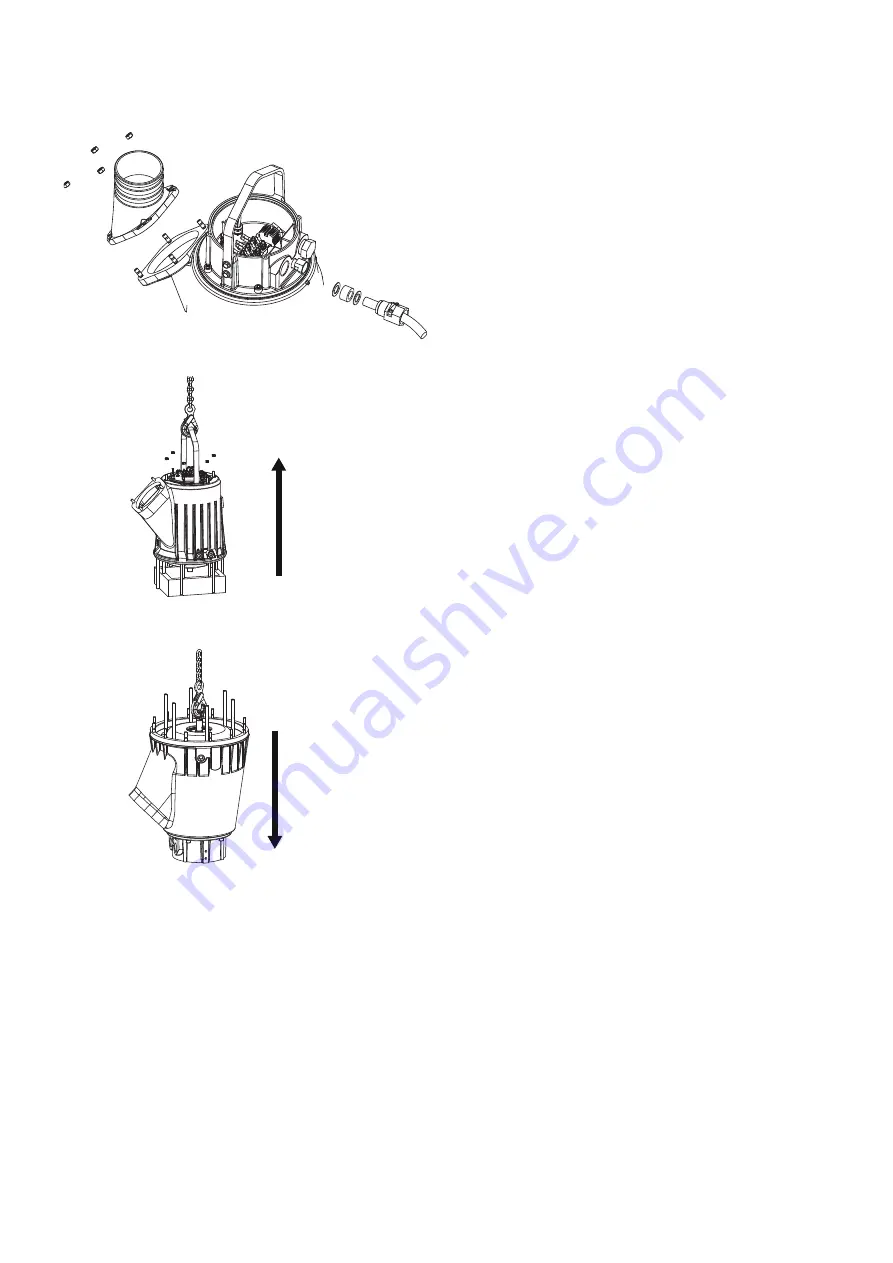

J 405:

Remove the handle from the pump when it is

lying down. Thread on an eye bolts on to the shaft end.

Lift the pump and place it in an upside down position on

the connection chamber secured by the lifting device.

Use a dead blow (plastic hammer) to force the cooling

jacket down until it releases from the motor housing. Lift

out the complete motor housing and put it lying down.

(Figure 15)

J 604:

Unscrew the lifting eye on top of the pump and

remove them. Fit an eye-bolt at the end of the shaft and

use a chain to lift and raise the pump into an upside

down position standing on the connection chamber.

Unscrew nuts to release the oil housing from the outer

jacket. Lift up and withdraw the motor housing and oil

housing together out of the cooling jacket.(Figure 15)

Figure 13: Cable and discharge removal

Figure 14: Cooling jacket removal (J 205)

Figure 15: Cooling jacket removal (J 405, J 604)

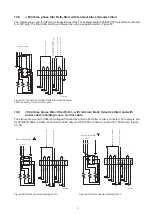

Summary of Contents for J 205

Page 30: ...30 11 Sectional drawing Tools J 205 ...

Page 31: ...31 J 405 ...

Page 32: ...32 J 604 ...

Page 37: ...37 ...