15

8.2

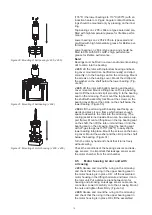

Mounting of new stator

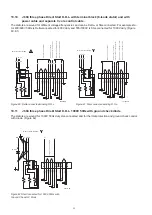

J 205, J 405:

(Figure 22, 23) Block up the new sta-

tor and make sure that the motor housing can be fully

pushed down onto the stator. Protect the stator insula-

tion from damages and fold stator cables together in

two groups and put them into a position so they can

easily be pulled up through the holes/openings in the

motor housing when stator is mounted. Avoid cables

to get in contact with the hot motor housing during as-

sembly. Make sure the motor housing is secured by the

lifting crane and that it can be fully lowered on to the

stator.

Use Two LP-gas flames to heat the housing till about

198º to 250ºC (388º to 482ºF). With two 25 mm nozzles

this will take about one minute.

Rotate the motor housing into a position, so the sta-

tor/ thermal/control cables can be pulled up smoothly

through the motor housing and later pulled through and

assembled on the terminal plate/upper bearing bracket.

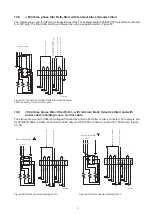

A stator lifting tool may be used for an alternative way

to lift back the new stator into the motor housing.

Check section 11 for part No. (Figure 22)

When the stator has been mounted the motor housing

may be cooled by compressed air.

Grease and mount the o-ring for the upper bearing in

the upper part of the motor housing on J 205.

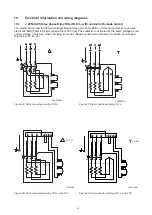

J 604:

(Figure 22, 24, 25) Block up the motor housing

and make sure that the new stator can be fully lowered

into the motor housing. Protect the stator insulation

from damages and fold stator cables together in two

groups and put them into a position so they can easily

be pulled up through the holes/openings in the motor

housing when stator is mounted. Avoid cables to get

in contact with the hot motor housing during assembly.

Make sure the stator is secured by the lifting crane and

that it can be fully lowered into the motor housing.

Use Two LP-gas flames to heat the housing till about

198º to 250ºC (388º to 482ºF). With two 25mm nozzles

this will take about one minute.

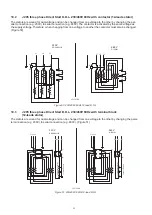

Rotate the stator into a position, so the two threaded

holes used by the locking key are placed on each side

of the axial groove in the motor housing (2xMC6S).

(Figure 25)

A stator lifting tool is used to lift back the new stator into

the motor housing. Check section 11 for part No. (Fig

-

ure 22)

When the stator has been mounted the motor housing

may be cooled by compressed air.

Grease and mount the o-ring for the upper bearing in

the upper part of the motor housing.

Figure 23: Mounting of Stator (J 205, J 405)

Figure 24: Mounting of Stator (J 604)

Figure 25: Axial groove in the motor housing (J 604)

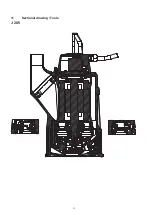

Summary of Contents for J 205

Page 30: ...30 11 Sectional drawing Tools J 205 ...

Page 31: ...31 J 405 ...

Page 32: ...32 J 604 ...

Page 37: ...37 ...