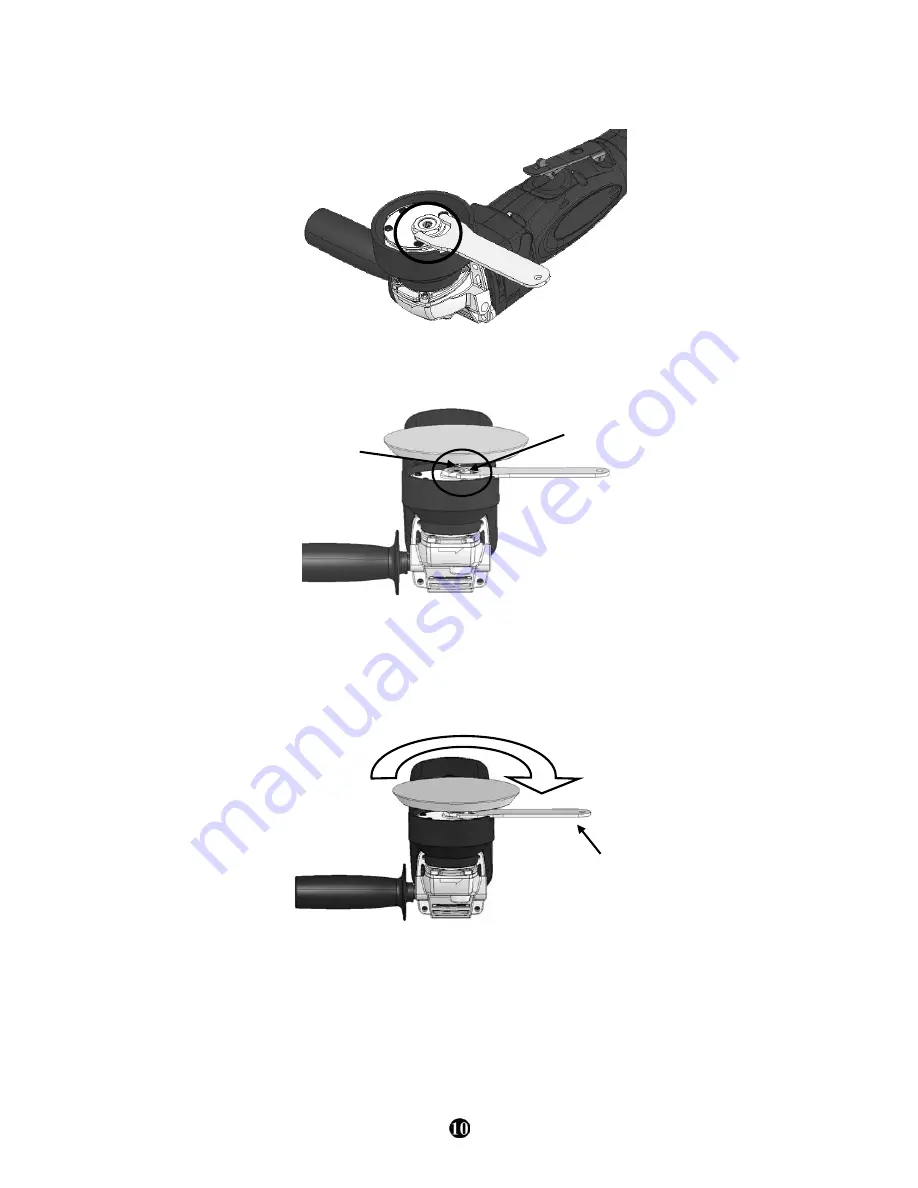

Attaching Polisher Backing Pad

1. Use polisher wheel flange wrench to hold the hexagonal nut.

2. Align the polisher backing pad bolt thread with the thread hole on the eccentric

wheel ass’y.

3. Use flange wrench to hold the hexagonal nut and stabilize the eccentric wheel

ass’y counter weight disc, spin the polisher backing pad in clockwise direction until

tightened. If baking pad came loosely, please use this same method to tighten the

backing pad.

Threads of eccentric

wheel ass’y

Use flange wrench to stabilize the

eccentric wheel ass’y.

Clockwise

Bolt Threads

Summary of Contents for EP-1800

Page 1: ...INSTRUCTION MANUAL ITEM NO EP 1800 18V 7 CORDLESS POWER POLISHER EP 1800 I 1403A TE...

Page 15: ...NOTE...

Page 16: ...NOTE...