Common

8. Daily Inspection and Maintenance

42

43

(3) Amount of oil

Table 8-5 shows approximate quantity of necessary oil. There are differences in the actual oil feed quantity among machines because

of the difference in structure and so on. Even if the feed quantity of lubricating oil is the same as that indicated in Table 8-5, the actual

quantity of oil in the product may be excessive or insufficient. For this reason, be sure to confirm that the oil level corresponds to the

center position of the oil gauge.

Table 8-5 Approximate Quantity of Oil (L)

Hollow Shaft Mount, Solid Shaft, Flange Type

Frame Size

Mounting Position

Y1

F1

G1

Y2

F2

G2

Y3

F3

G3

Y4

F4

G4

Y5

F5

G5

Y6

F6

G6

72, 72DA

82, 82DA

92, 95, 92DA

102, 105, 102DA

112, 115, 112DA

1.9

3.4

4.1

6.7

9.5

8.3

11.5

15.8

23.0

33.2

5.7

7.6

10.2

14.9

21.0

4.8

6.8

7.9

14.2

16.8

3.3

4.7

5.9

9.1

12.2

5.7

7.8

11.1

14.9

19.2

Solid Shaft, Foot Type

Frame Size

Mounting Position

K1

K2

V2

K3

K4

K5

K6

72, 72DA

82, 82DA

92, 95, 92DA

102, 105, 102DA

112, 115, 112DA

2.1

3.2

4.1

6.7

8.6

7.6

10.7

14.1

22.2

29.6

5.0

6.8

9.1

14.3

18.5

4.5

5.9

6.8

12.9

15.0

2.8

4.0

5.1

8.6

10.7

5.4

7.4

9.7

15.3

20.4

(4) Procedure for Oil Feed and Discharge

- Oil Feed Procedure

(1) Remove the oil filler plug.

(2) With checking the oil level on the oil gauge, add oil from the oil filling port.

(3) Confirm that the oil level corresponds to the center position of the oil gauge.

(4) Install the oil filler plug.

- Oil Discharge Procedure

Remove the plug of the oil drain port and discharge the oil.

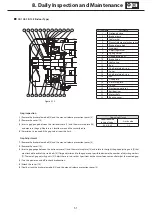

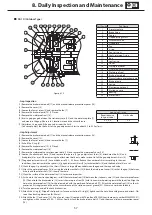

Figure 8-3 Oil Gauge

Figure 8-2 Locations of Oil Filling/Drain Ports

(E.g.: KHYM-Y2)

Figure 8-1 Locations of Oil Filling/Drain Ports

(E.g.: KHYM-Y1)

For the locations of oil filling/drain ports other than the above, see P10 to 14.

Oil filler plug, oil filling port

Oil gauge

Oil drain port