Cyclo® HBB

Operation & Maintenance Manual

19

Cyclo® HBB

Removal from Driven Shaft

Cyclo® HBB with Taper-Grip® Bushing

Before starting the removal process, ensure that electrical power to the unit

has been safely locked out and electrical connections to the unit have been

disconnected

1

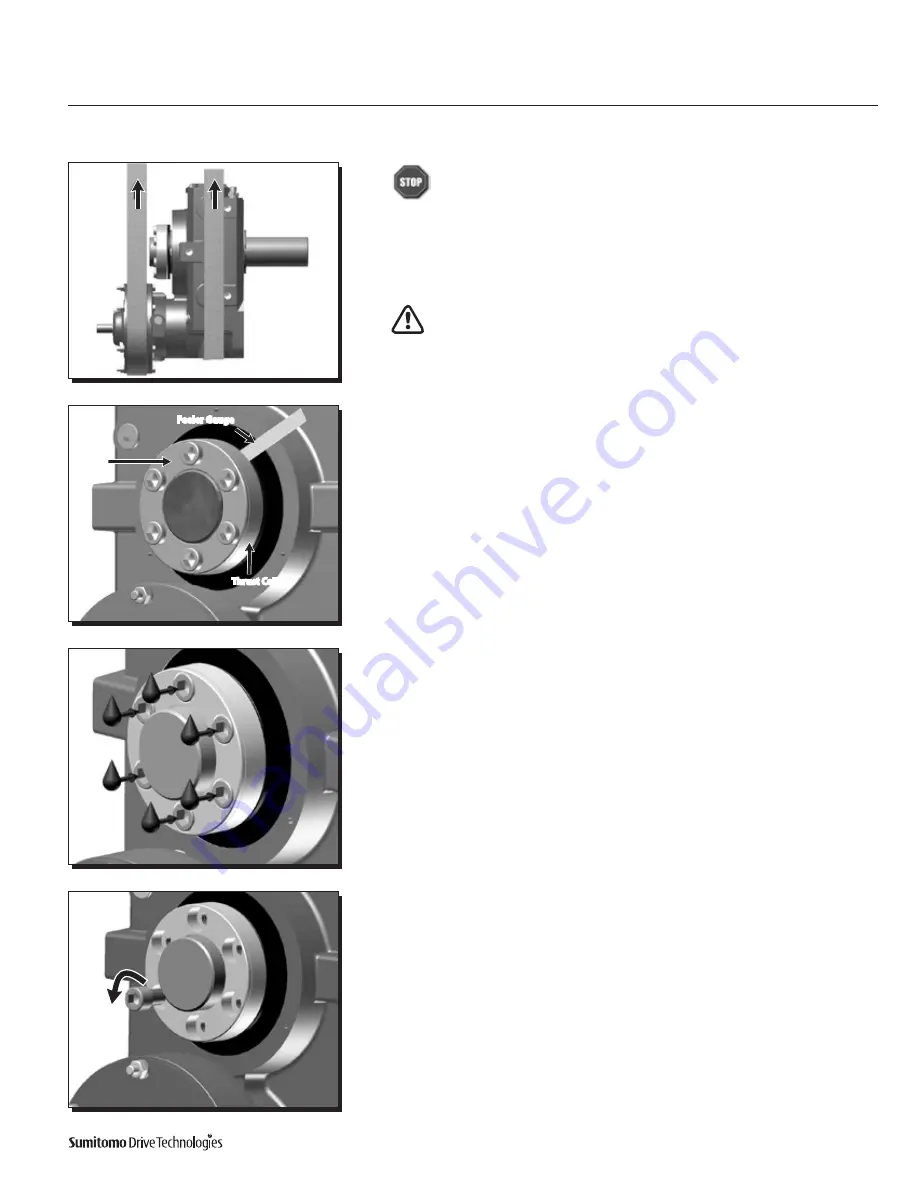

Externally support the Cyclo® HBB so that all the unit’s weight is removed from the

driven shaft

The weight of the Cyclo® HBB must be externally supported throughout the

entire removal process

Do not raise the unit too high!

Shaft binding may occur

2

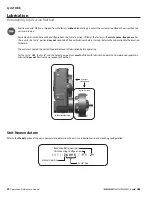

Inspect the Taper-Grip® Bushing to assure that a gap exists between the thrust collar

and the bushing flange

3

Apply a liquid-penetrant onto each of the Taper-Grip® Bushing socket-head cap

screws Allow time for the penetrant to settle into the threads of the screws

4

After the penetrant has settled, remove the socket head cap screws

one at a time

Bushing

Flange

1-3mm

Feeler Gauge

Thrust Collar

Summary of Contents for Cyclo HBB

Page 1: ...0 7 6 0 1 6 0 0 0 3 H B B O M2 0 1 8...

Page 27: ...MA X MI N...