Operation & Maintenance Manual

29

Cyclo® HBB

Cyclo® HBB

Grease Replenishment and Draining Procedure

Procedure for adding grease to grease-lubricated models (excluding maintenance-free models)

1 Remove the grease discharge plug from the outside cover

2 Add grease with a grease gun from the grease nipple in the inside cover section or motor connection cover

3 Insert the grease discharge plug

• Add grease during operation to ensure proper, uniform circulation.

• Add grease slowly.

• Do not add more grease than the amount shown in

Table 17

and

18

Adding too much grease may cause the grease

temperature to rise, or grease to leak into the motor.

Grease Replacement for Grease-Lubricated and Maintenance-Free Grease Models

• The unit may be safely operated for an extended time because it is sealed with maintenance-free grease. However, Sumitomo

recommends overhauling every 20,000 hours or 3-5 years of operation to ensure long service life

• Always consult our specialized factory for overhaul of gearmotors and reducers. Experience is necessary for overhaul.

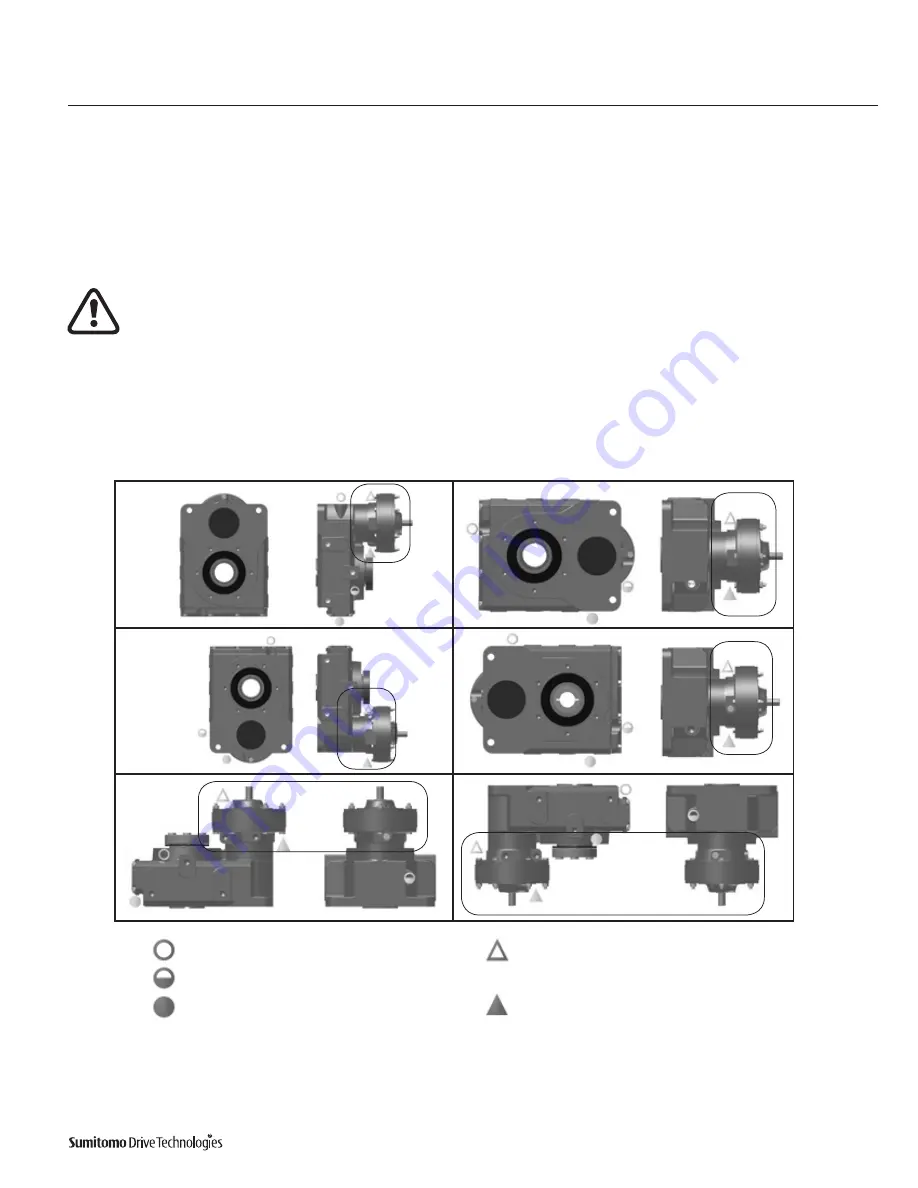

Fig 5 Grease Fill/Drain Locations

Lubrication

Grease Replenishment / Draining

Y3

Y4

Y1

Y2

Y5

Y6

= Helical Gear Portion Oil Fill Location

= Helical Gear Portion Oil Sight Gauge Location

= Helical Gear Portion Oil Drain Location

= Cyclo® Portion Grease Fill Location

= Cyclo® Portion Grease Drain Location

Summary of Contents for Cyclo HBB

Page 1: ...0 7 6 0 1 6 0 0 0 3 H B B O M2 0 1 8...

Page 27: ...MA X MI N...