Cyclo® HBB

Operation & Maintenance Manual

45

Cyclo® HBB

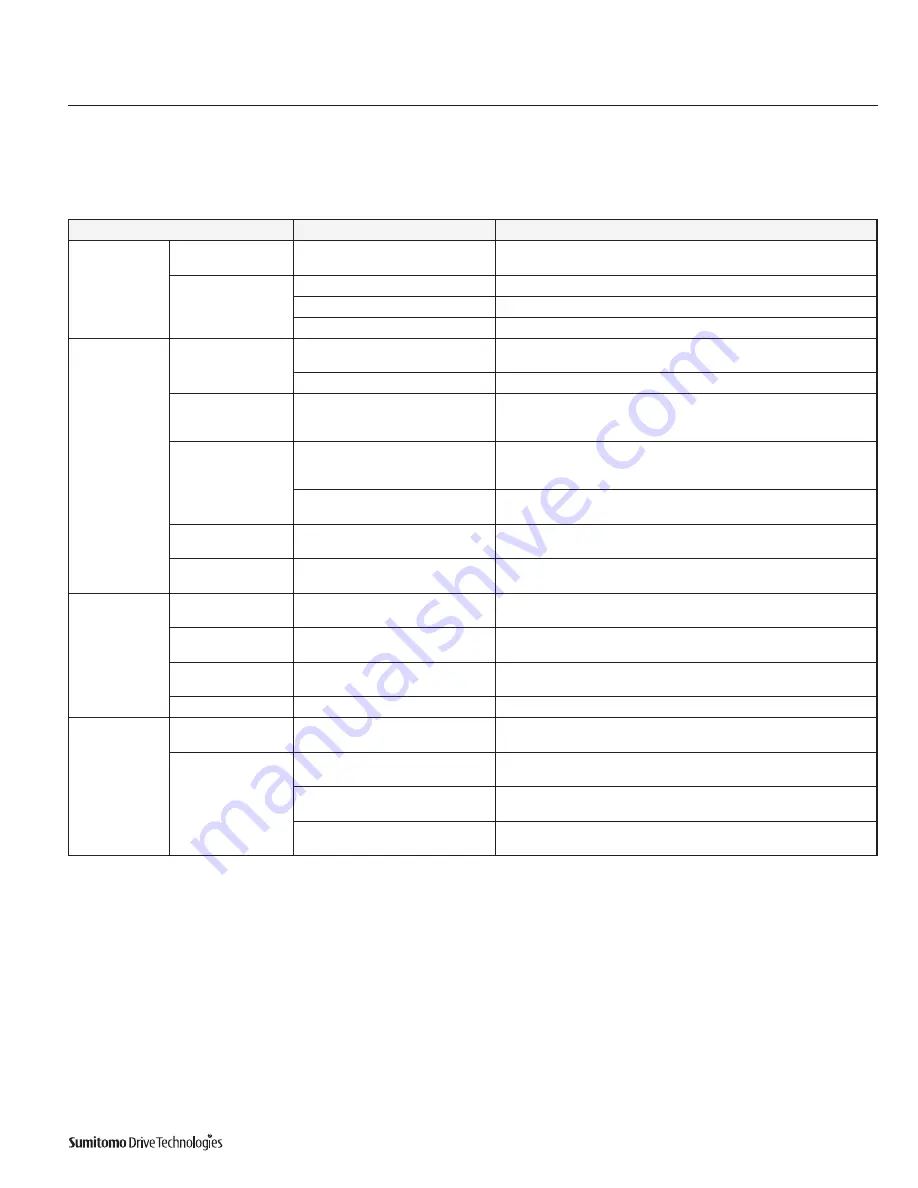

Troubleshooting

This troubleshooting guide provides assistance in identifying and overcoming common problems in reducers and motors If you have a

problem with the reducer and/or the motor that is not listed below, please consult the factory for assistance

Problem with the Reducer

Possible Causes

Suggested Remedy

Runs Hot

Overloading

Load exceeds capacity of the reducer

Check the rated capacity of the reducer, replace with unit of sufficient capacity

or reduce the load

Improper lubrication

Insufficient lubricant

Check lubricant level and increase to recommended levels.

Excessive lubricant

Check lubricant level and reduce to recommended level.

Incorrect lubricant

Flush old lubricant from the unit and refill with correct recommended lubricant

Vibration or

Noise

Loose foundation bolts

Weak mounting structure

Inspect mounting of reducer Tighten loose bolts and/or reinforce mounting &

structure

Loose hold-down bolts

Tighten bolts

Worn disc and/or helical

gearing

Overloading of the unit may result in

damage to the Helical gearing and/or the

Cycloid discs

If helical gearset is damaged, contact the factory

If Cycloid discs are damaged, disassemble the Cyclo® portion and replace discs

Re-check the rated capacity of the unit.

Bearing Failure

May be due to lack of lubricant

If output bearings are damaged, contact the factory

If bearings in Cyclo® portion are damaged, replace the affected bearings Clean &

flush the reducer and fill with the correct type and quantity of lubricant

Overload

Check the rated capacity of the reducer. Replace with unit of sufficient capacity

or reduce the driven load

Insufficient Lubricant

Level of lubricant in the reducer not

properly maintained

Check lubricant level and adjust to factory-recommended level.

Damaged Cyclo® pins

and rollers

Overloading of reducer

Disassemble Cyclo® portion of reducer and replace ring

gear housing pins and rollers. Check load on reducer.

Output

Shaft/Hub does

not turn

Motor shaft broken

Overloading of reducer can cause

this type of damage

Replace broken shaft. Check rated capacity of reducer.

Input shaft key missing

or broken

Replace key.

Eccentric bearing

broken

Lack of Lubricant

Replace the Eccentric Bearing in the Cyclo® portion Flush

and refill the unit with the recommended lubricant

Motor does not turn

Motor

Refer to the “Motor” portion of this Troubleshooting guide

Oil Leakage

Worn seals

Caused by dirt or grit entering the seal

area

Replace the oil seals The breather filter may be clogged Replace or clean filter

Leakage into motor

Reducer has been overfilled with

lubricant

Check the lubricant level and adjust to the recommended level.

Air breather clogged

Clean or replace element, being sure to prevent any dirt from falling into the

reducer

Improper mounting position, such as

other than designed mounting angle

Mount the unit in it’s designed mounting angle

Summary of Contents for Cyclo HBB

Page 1: ...0 7 6 0 1 6 0 0 0 3 H B B O M2 0 1 8...

Page 27: ...MA X MI N...