27

26

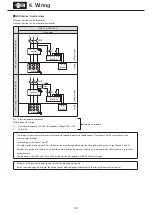

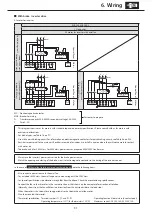

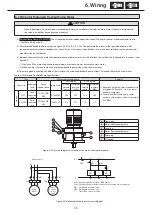

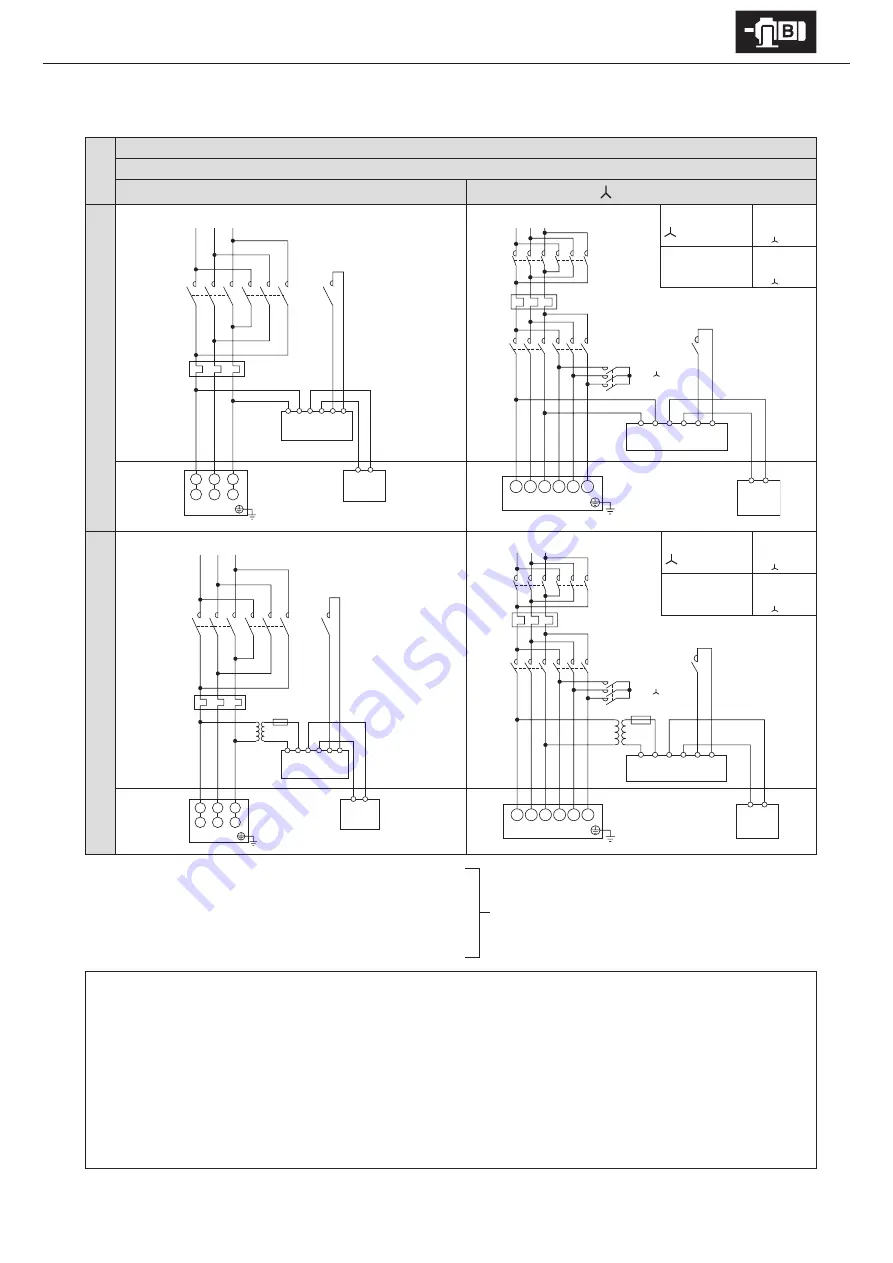

6. Wiring

■

With Brake. 3-phase motor. Plugging operation

Premium-efficiency, 3-phase motor

ESB-250, ESB-250-2

8 lead wires

Direct on-line starting

‒Δ

starting

Q

uick br

ak

ing cir

cuit 200V class

Con

tr

ol P

anel

At start

Wiring

MC

M

ON

MC

Δ

OFF

MC ON

When acceleration

is completed

Δ wiring

MC

M

ON

MC

Δ

ON

MC OFF

Con

tr

ol P

anel

M

ot

or

M

ot

or

Q

uick br

ak

ing cir

cuit 400V class

Con

tr

ol P

anel

At start

Wiring

MC

M

ON

MC

Δ

OFF

MC ON

When acceleration

is completed

Δ wiring

MC

M

ON

MC

Δ

ON

MC OFF

Con

tr

ol P

anel

M

ot

or

M

ot

or

Electromagnetic contactor for normal and reverse rotation

MC: Electromagnetic contactor

OLR: Overload protection device or electronic thermal relay

Tr: Transformer capacity 250–600VA, secondary voltage 200–220V

F:

Fuse 3–5A

Customer to prepare.

-This diagram shows cases for motors with standard Japanese domestic specifications. Please consult with us for motors with

overseas specifications.

-For brake types, see Table 1-6 on P7.

-Use with a quick braking circuit. For information on electromagnetic contactors for quick braking circuits, see Table 6-4 on P32.

-Rectifiers are external to the main unit. Rectifiers are made for indoor use. Install in an area where they will not come into contact

with water, etc.

-The brake unit is for 200V class. For 400V class power sources, prepare a 400V/200V transformer.

-For plugging operations, gang the brake circuit’s electromagnetic contactors to the motor’s normal and reverse rotation

electromagnetic contactors

U1

V1 W1

V2 W2 U2

1 2 3 4 5 6

4 3

Rectifier

Brake

MC

OLR

Motor

R S T

U1 V1 W1

V2 W2 U2

1 2 3 4 5 6

4 3

Rectifier

Brake

MC

OLR

Tr F

400V

200V

Motor

R S T

Normal rotation

Rev

erse rotation

MC

M

MC

Δ

MC

OLR

U1 V1 W1 V2 W2 U2

1 2 3 4 5 6

4 3

Motor

Rectifier

Brake

R S T

Normal rotation

Rev

erse rotation

Tr F

400V

200V

MC

M

MC

Δ

MC

OLR

U1 V1 W1 V2 W2 U2

1 2 3 4 5 6

4 3

Motor

Rectifier

Brake

MC

MC

R S T

Normal rotation

Rev

erse rotation

Normal rotation

Rev

erse rotation