36

8. Daily Inspection and Maintenance

Common

DANGER

-

Do not handle the unit when cables are live. Be sure to turn off the power when operating on the unit; otherwise, electric shock may result.

-

Do not approach or touch any rotating parts (slow speed shaft, etc.) during run-time maintenance or inspection of the unit; loose clothing may become caught

in these rotating parts and cause serious injury or death.

-

Customers must not disassemble or modify

For explosion proof motors

; otherwise, explosion, ignition, electric shock, or damage to the equipment may result.

-

The lead-in condition of an

For explosion proof motors

, shall conform to the facilities electrical codes, extension regulations, and explosion-

proofing guide, as well as the maintenance manual; Additionally, do not open the terminal box cover while operating. otherwise, explosion,

ignition, electric shock, or damage to the equipment may result.

-

Do not operate the machine while the brake is released by the manual brake release bolt; otherwise, falling, going out of control, or damage to the equipment

may result.

CAUTION

-

Do not put fingers or foreign objects into the opening of the products; otherwise, electric shock, injury, fire, or damage to the equipment may result.

-

The products becomes very hot during operation. Touching the unit with bare hands may result in serious burns.

-

Do not touch the terminals when measuring insulation resistance; otherwise, electric shock may result.

-

Do not operate the unit without a safety cover (removed during inspection) in place to shield rotating parts; otherwise loose clothing may became caught in

these rotating parts and cause serious injury or death.

-

Promptly identify and correct, according to instructions in this maintenance manual, any abnormalities observed during operation. Do not operate until the

cause for the abnormality is understood, and the abnormality is corrected.

-

Change lubricant according to the maintenance manual instructions. Be sure to use factory recommended lubricant.

-

Only install, move, or transport oil-lubricated models with lubricating oil removed. Moving with lubricating oil in the machine may cause oil to escape from the

air vent, etc.

-

Do not change lubricant during operation or immediately after stopping operation; otherwise, burns may result.

-

Supply/discharge grease to/from the motor bearing according to the maintenance manual instructions. Avoid contact with rotating parts; otherwise, injury

may result.

-

Do not operate damaged gearmotors or reducers; otherwise, injury, fire, or damage to the equipment may result.

-

We cannot assume any responsibility for damage or injury resulting from an unauthorized modification by a customer, as it is outside the scope of the

warranty.

-

Dispose of products lubricant as general industrial waste.

-

When measuring the insulation resistance of an

For explosion proof motors

, confirm that there is no gas or other vaporized explosive substance around the

unit in order to prevent explosion or ignition.

-

Changing brake linings requires experience. Consult with the nearest authorized service station.

-

Brake torque will change with operation environment and conditions, the condition of the friction surface, and other factors. In particular, brake torque may

not be at the prescribed level for initial operation, and after a long period of inactivity. In such a case turn the brake on and off under as light load as possible

to contact the brake’s friction surfaces.

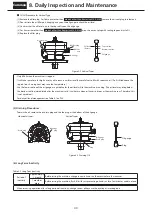

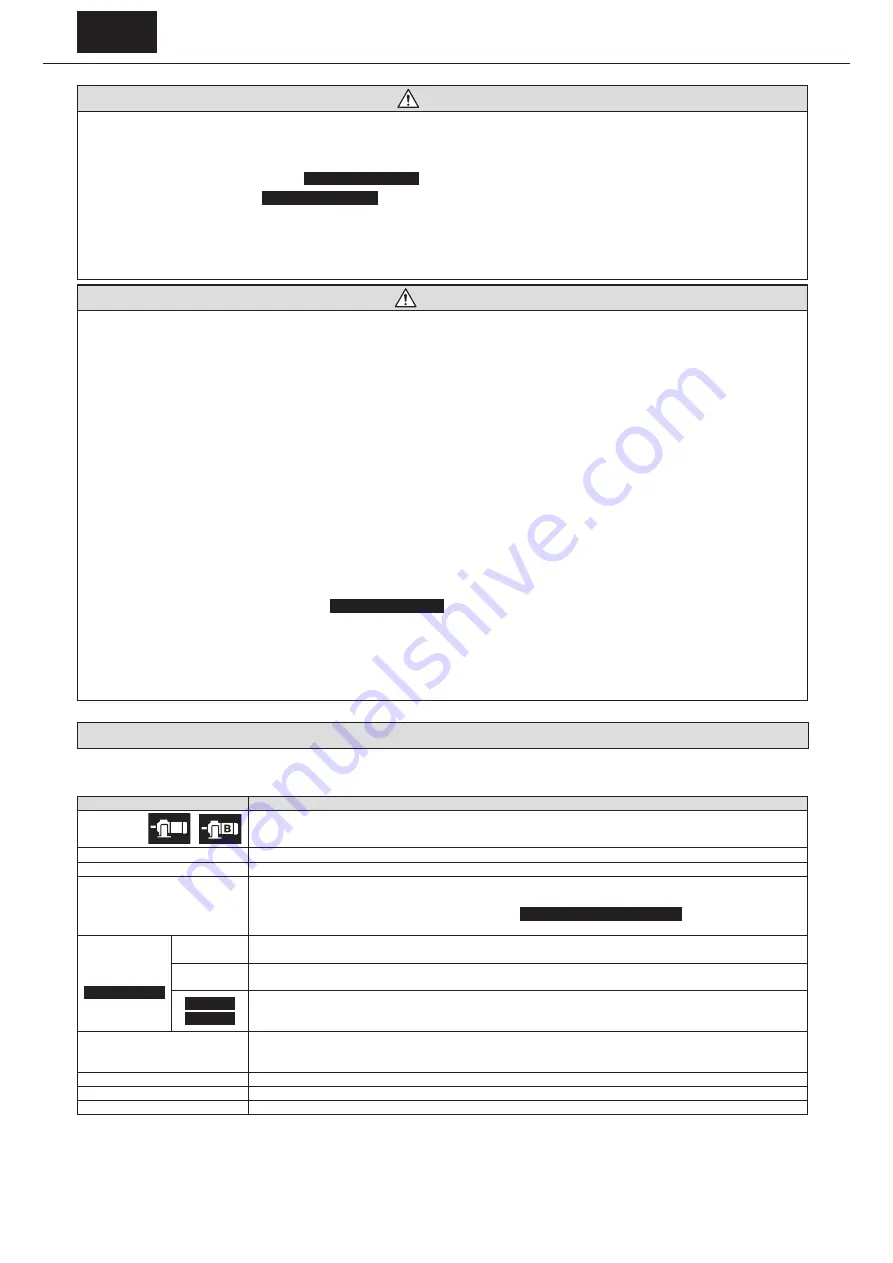

8-1. Daily Inspection

Make certain to carry out daily inspections in accordance with Table 8-1. Neglecting inspections is a source of trouble.

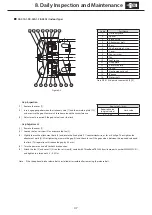

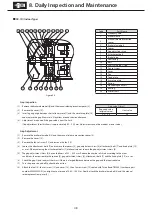

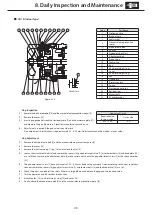

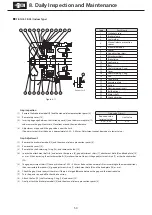

Table 8-1 Daily Inspection

Inspection item

Inspection detail

Current value

Is the current no greater than the rated value shown on the nameplate?

Noise

Are there unusual noises, or are there extreme changes in the noises?

Vibration

Is there abnormally large vibration? Are there extreme changes?

Surface temperature

Is surface temperature unusually high? Has there been a sudden rise?

Temperature rises during operation will differ according to model and type. However the difference between the gear unit surface temperature

and the environment temperature should be approximately 60

℃

. (For

Frame size 6060 – 6125, and SK series

approximately 40

℃

) In this

case, there is no particular problem if fluctuation is slight.

Oil level

(

Oil lubricated machines

)

At rest

Is the oil level below the red line at the top of the oil gauge when the machine is at rest?

If when at rest the oil level is below the top red mark, fill up to the mark with lubricating oil. Do no add while the machine is running.

While running

Is the oil level significantly different than the level during stable operation?

The bottom red mark is an auxiliary mark serving as a guideline to check oil level while the machine is running.

Trochoid

pump type

Are the oil signal and flow gauge working properly?

Their no working properly is a sign of improper reducer lubrication, due to factors including insufficient oil, pump damage and plugged

pipes. Immediately stop the machine and inspect.

Lubricant contamination

Is the lubricating oil contaminated?

To check for oil contamination, in addition to extracting oil while the machine it stopped, it is also possible to check using the oil gauge.

If the oil gauge is contaminated, promptly change it.

Oil, grease leaks

Are oil or grease leaking from the gear unit? Are the oil seal sliding surfaces corroded?

Mounting bolts

Are the mounting bolts loose?

Chain, V-belt

Are the chain or V-belt loose?

- If any abnormality is discovered during the daily inspection, take measures in accordance with “9. Troubleshooting” (P72, 73). If these actions do not remedy the issue,

immediately contact the nearest authorized service station.

)

)