37

36

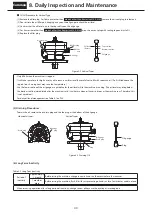

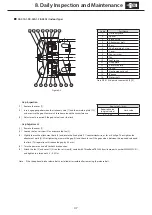

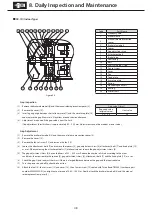

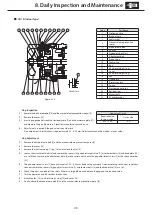

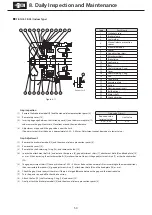

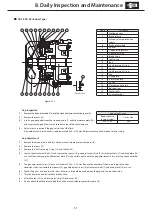

8. Daily Inspection and Maintenance

Common

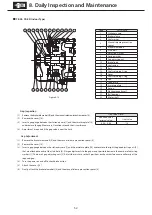

8-2 Confirmation of Lubrication Method

Please look for the relevant items and make certain to do maintenance. Neglecting maintenance is a source of trouble.

- Check Table 8-2 for the lubrication method employed by the gear unit of the model used.

- Table 8-3 lists pages that can be referenced regarding lubrication maintenance.

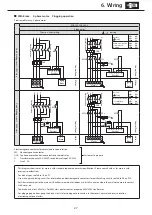

Table 8-2 Standard Lubrication Methods for Gear Units by Type (When driven at standard input speed)

SK ser

ies

Frame size 607

□

SK 608

□

SK 609

□

SK 610

□

SK 611

□

SK

Horizontal

Long-life grease

Vertical

Lo

w r

educ

tion

ra

tio ser

ies

Frame size

613

□

614

□

616

□

617

□

Horizontal

Oil Bath

Vertical

Single R

educ

tion

Frame size

606

□

607

□

608

□

609

□

610

□

611

□

612

□

613

□

614

□

616

□

617

□

618

□

619

□

6205 6215 6225 6235 6245 6255 6265 6275

Horizontal

Long-life grease

Oil Bath

Vertical

Oil Bath

Plunger pump (force-feed lubrication)

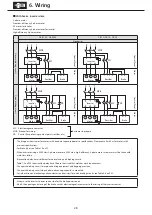

Frame

size

606

□

DA

607

□

DA

609

□

DA

610

□

DA

612

□

DA

612

□

DB

613

□

DA

613□DB

613□DC

614

□

DA

614□DB

614□DC

616□DA

616□DB

617□DA

617□DB

618□DA

Horizontal

Long-life grease

Grease

Vertical

D

ouble R

educ

tion

Frame

size

616

□

DC

617

□

DC

618

□

DB

619

□

DA

619

□

DB

6205DA

6205DB

6215DA

6215DB

6225DA

6225DB

6235DA

6235DB

6245DA

6245DB

6255DA

6255DB

6265DA

6275DA

Horizontal

Oil Bath

Ver

tical

Reduction

ratio

– 473

– 841

– 1015

– 2065

– 1849

– 2537

Plunger pump (force-feed lubrication)

Reduction

ratio

493 –

1003 –

1247 –

2537 –

2065 –

3045 –

Grease

Triple R

educ

tion

Frame

size

606

□

TA

607

□

TA

609

□

TA

610

□

TA

612

□

TA

612

□

TB

Frame sizes not listed to the left

Horizontal

Long-life grease

Grease

Vertical

Note : 1.

Indicates universal mounting direction.

2.

Indicates independent lubrication using a trochoid pump. See “6-7 Wiring for Motorized Trochoid Pump Motor” (P33)

3. The symbol

□

in frame size can be "0", "5” or "H".

4. For underlined frame sizes, the horizontal chain flight sludge collector specification is set to oil lubrication.

5. If input speed is not standard, consult with us.

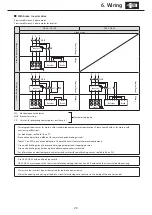

Table 8-3 Maintenance Manual Pages that can be Referenced Regarding Lubrication Maintenance

Lubrication method

Oiling, greasing at

time of purchase,

prior to operation

Location of information on maintenance technique

Oil, grease

change, replenish

intervals

Recommended lubricating

oil,

grease

Oil fill quantity

Grease supply

quantity

Oil fill and drain procedures

Grease supply and discharge

procedures

G

ear unit

Oil lubr

ica

tion

Oil Bath

Self-lubricating

Required

8−3

(1)

P38

8−3

(2)

P38

8−3

(3)

P39

8−3

(4), (5)

P39, 40

Plunger

system

force-feed

lubrication

Trochoid

system

Independent

lubrication

Gr

ease lubr

ica

tion

Long-life grease

Self-lubricating

Not required

8-4

(1)

P41

8-4

(2)

P41

8-4

(3)

P42

8-4

(4)

P43

Other than long-life

grease

M

ot

or bear

ing unit

Gr

ease lubr

ica

tion

Self-lubricating

Not required

8-6

(1)

P44

8-6

(2)

P45

8-6

(1)

P44

8-6

(3)

P45

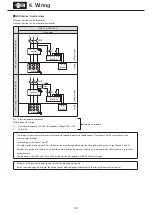

Note : For plunger pump type (force-feed lubrication) models, in the case that the slow speed shaft does not rotate continuously (example: the slow speed

shaft only rotates 90° or less), consult with us. As Figure 10-2 on P74 shows, plunger pump [40] is driven by cam [47] on the slow speed shaft unit. If the

machine is not driven at a continuous, standard input speed, consideration must be made for providing sufficient lubrication to the reducer.