38

8. Daily Inspection and Maintenance

Common

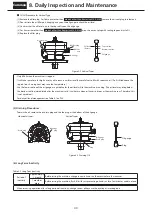

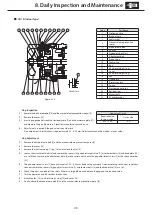

8-3 Oil Supply and Oil Change for Oil Lubricated Gear Units

(1) Oil Change Interval

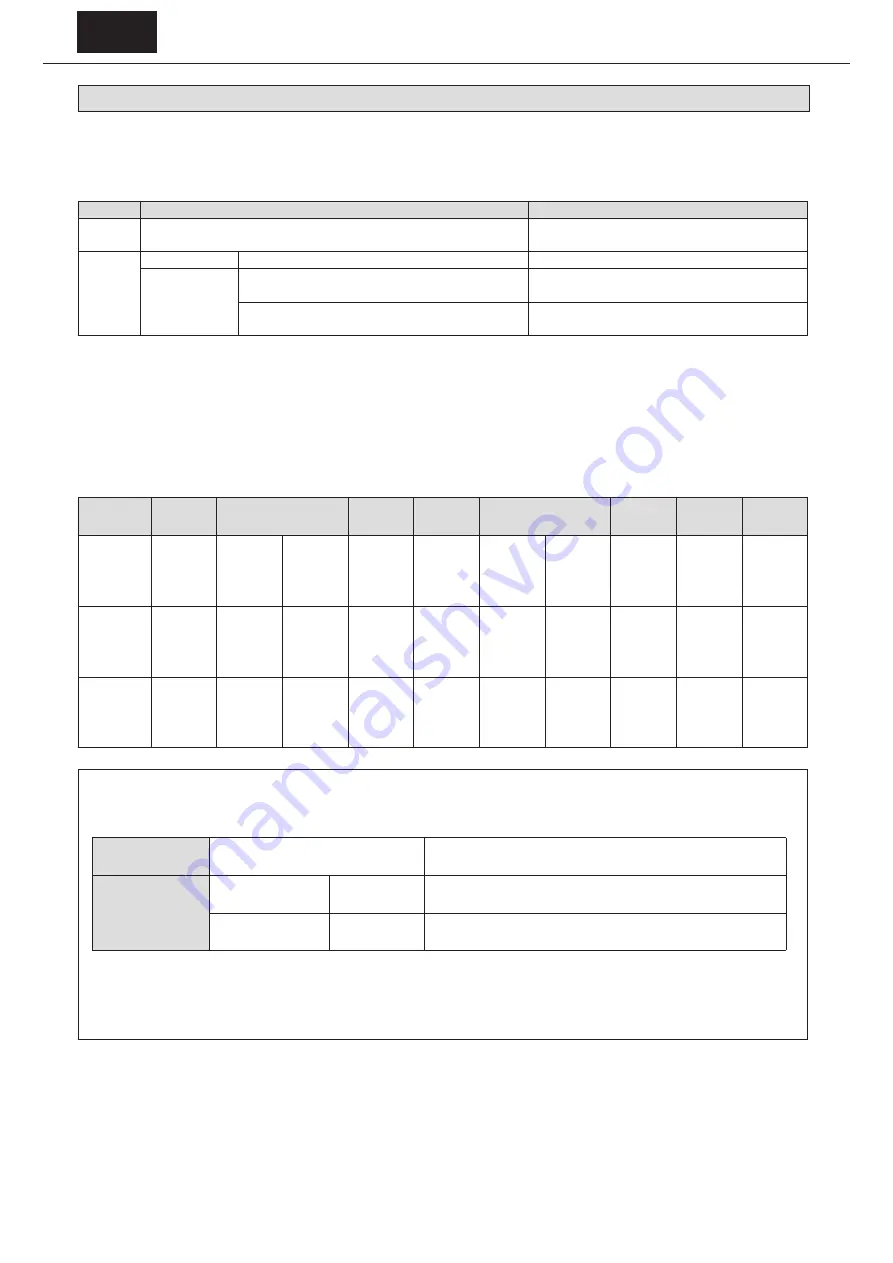

Table 8-4 Lubricating Oil Inspection and Change Intervals

Change Interval

Operating Condition

Oil

supply

Time of purchase

−

Oil

change

First time

After 500 hours or 6 months, whichever comes first.

−

2nd. and

subsequent

times

Every 5,000 hours, or every year, whichever comes

first.

Indoors, etc. at 0 to 35 °C

Every 2,500 hours, or every 6 months, whichever

comes first.

Outdoors or hot locations, etc., where 0 to 35 °C

cannot be maintained.

- Oil degrades more rapidly when ambient temperature is high or changes radically, and when corrosive gases are present. In such

cases confer with the lubricating oil manufacturer.

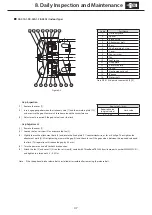

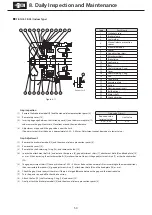

(2) Recommended Lubricating Oil

Always use lubricating oils recommended by Sumitomo Heavy Industries as shown in Table 8-5.

Table 8-5 Recommended Lubricating Oils (Equivalent to SP type industrial high-pressure gear oil or JIS K2219)

Ambient

temperature °C

COSMO

ENEOS

IDEMITSU

Shell

Mobil

Gulf

CALTEX

bp

-10 to 5

COSMO

GEAR SE

68

BONNOC

M

68

−

Daphne

Super

Gear Oil

68

Shell Omala

S2 G

68

−

Mobilgear

600 XP

68

Gulf EP

Lubricant HD

68

–

Energol

GR-XP

68

0 to 35

COSMO

GEAR SE

100, 150

BONNOC

M

100, 150

BONNOC

TS

150

Daphne

Super

Gear Oil

100, 150

Shell Omala

S2 G

100, 150

Spartan EP

150

Mobilgear

600 XP

100, 150

Gulf EP

Lubricant HD

100, 150

Meropa

100, 150

Energol

GR-XP

100, 150

30 to 50

COSMO

GEAR SE

220 - 460

BONNOC

M

220 - 460

BONNOC

TS

220 - 460

Daphne

Super

Gear Oil

220 - 460

Shell Omala

S2 G

220 - 460

Spartan EP

220 - 460

Mobilgear

600 XP

220 - 460

Gulf EP

Lubricant HD

220 - 460

Meropa

220 - 460

Energol

GR-XP

220 - 460

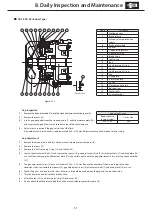

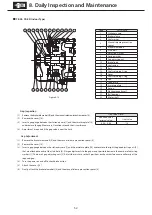

[1] When using in winter or where the ambient temperature is relatively low, use an oil with a viscosity at the lower end of the range.

[2] For allowable lubricating oil viscosity see Table 8-6. Use within this required viscosity range.

Table 8-6 Allowable Oil Lubricant Viscosity

Minimum allowable

viscosity

For oil temperature during operation,

minimum 15mm

2

/S.

Viscosity that will obtain required film strength under load.

Maximum allowable

viscosity

Oil bath lubricated

models

Maximum

4,300mm

2

/S

Viscosity at which Cyclo Drive can start

Force feed lubricated

models

Maximum

2,200mm

2

/S

Viscosity at which the plunger pump and motorized trochoid pump

can start.

[3] For a smooth startup use oil with a pour point at least 5

℃

below ambient temperature.

[4] If operating temperature changes within a wide range use a high viscosity index oil that meets requirements [2] and [3].

[5] If regularly operating outside the ambient temperature range of 0 to 40

℃

, some parts of the mechanism may need to be

changed, and lubricating oil might need to be preheated, or cooled. Please consult with us.