44

8. Daily Inspection and Maintenance

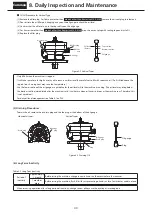

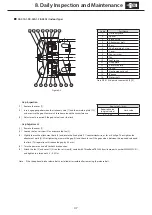

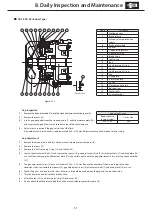

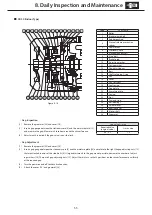

8-6 Motor Bearing Maintenance

Bearing type and maintenance technique will vary according to motor frame size. When maintaining, confirm the bearing type by

referring to the nameplate and Table 8-14.

When using a vector motor, other manufacturer’s motor (There are some models made by other manufacture.), refer to the operation

manual for that motor.

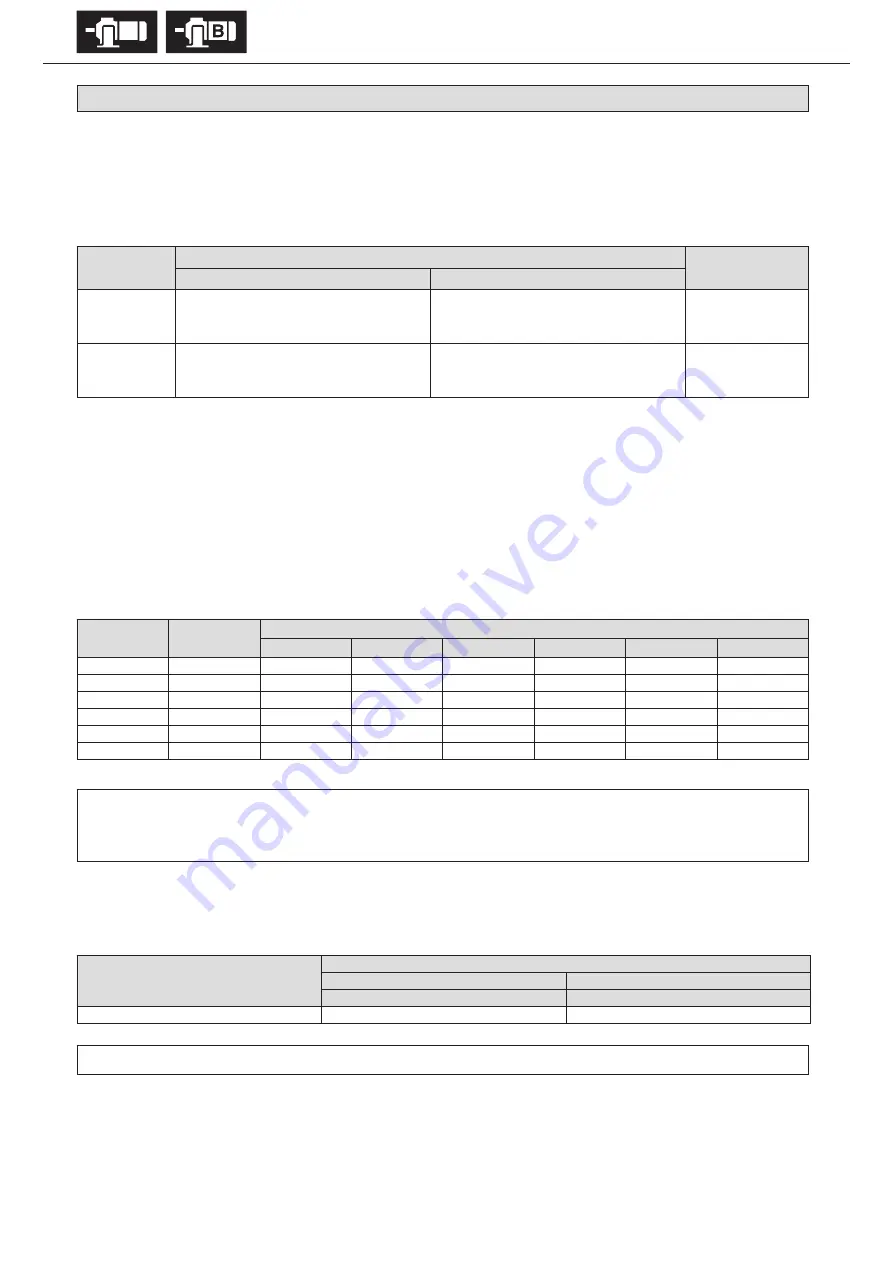

Table 8-14 Bearing Types

Bearing type

- Specified motor (frame size)

Remarks

Load side

Anti-load side

Sealed bearing

- Motor frame size 160 and lower

- Motor frame size 180 and higher, at the same

time Cyclo frame size 6225 and lower

All motors except the following.

Not constructed for

filling or draining

grease

Open bearing

- Motor frame size 180 and higher, at the same

time Cyclo frame size 6235 and higher

- Motor frame size F-200L (increased safety,

explosion proof),

at the same time

Cyclo

frame size 6255 and 6265

With grease fitting

and grease discharge

plug

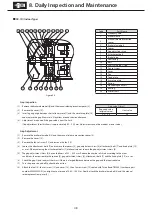

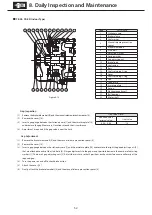

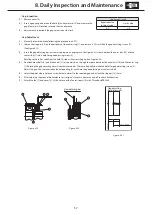

(1) Sealed Bearing Maintenance

Although it will depend on operation conditions, maintenance with disassembly after approximately 20,000 hours or 3 to 5 years will

further increase lifetime.

Contact the nearest authorized service station regarding maintenance with disassembly.

(2) Open Bearing Maintenance

Check the bearing number on the nameplate, and replenish grease in accordance with with Table 8-15.

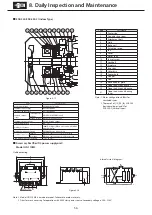

Table 8-15 Open Bearing Grease Replenishment Intervals and Replenishment Quantity

Bearing number

Replenishment

quantity (g)

Grease replenishment interval (interval (h) for speeds (r/min))

720 r/min

870 r/min

980 r/min

1165 r/min

1450 r/min

1750 r/min

NU314

40

4000

3500

3000

2500

1500

1000

NU315

45

4000

3000

3000

2000

1500

1000

NU316

50

4000

3000

2500

2000

1500

1000

NU317

55

3500

3000

2500

2000

1500

1000

NU318

60

3500

2500

2500

2000

1000

1000

21312

30

1500

1000

1000

800

-

-

-The replenishment quantity is the quantity to insert at each interval.

-Even in the case of intermittent operation, replenish grease approximately every 3 years.

-If the machine is rested for a long time, replenish grease immediately after resuming operation.

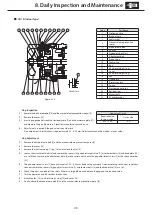

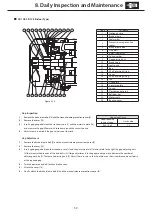

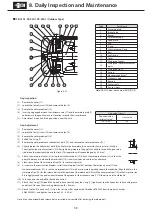

(3) Recommended Grease for Open Bearings

Table 8-16 Recommended Grease

Ambient temperature

℃

Open Bearing

Thermal class 130 (B)

Thermal class 155 (F)

Mobil

Shell

−10 to 40

UNIREX N2

Shell Stamina Grease RL2

Avoid using grease other than that listed in Table 8-16.