45

44

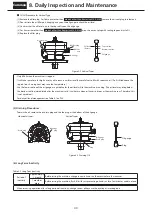

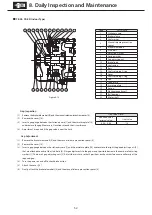

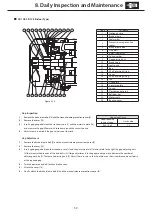

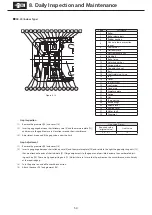

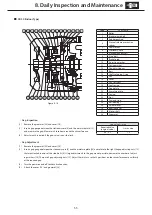

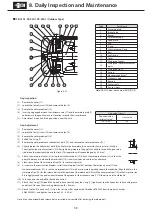

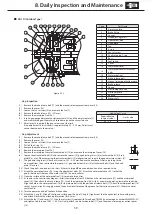

8. Daily Inspection and Maintenance

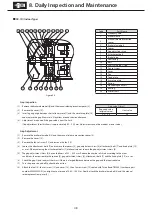

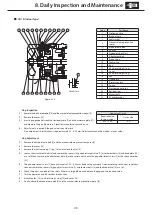

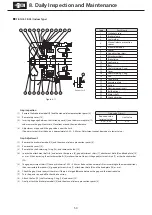

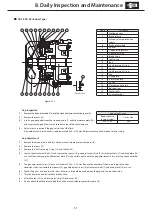

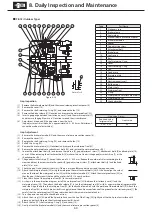

(4) Procedures for Filling and Discharging Grease for Open Bearings

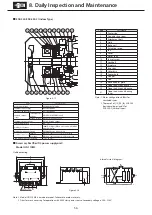

See construction diagram 8-7.

[1] Remove the discharge port plug, and discharge the old grease. While the machine is running replenish with new grease through

the grease fitting.

(Grease change will be incomplete if replenishing is done while the machine is stopped.)

[2] Run the machine for approximately 10 minutes after the grease is inserted. Then fasten the discharge port plug.

-Overfilling could cause the bearing to overheat, grease to leak and other problems. Be careful.

-Do not think that it is allowable to replenish with a large quantity to extend the replenishment interval.

-Please maintain the machine properly. Neglecting replenishment when resuming operation, or periodic replenishment when the

machine is operating could lead to abnormal wear, bearing noise, bearing burnout, and other problems.

Load side cover

Motor shaft

Bearing

Bearing cover

Discharge port

Grease fitting

Motor shaft

Bearing

Bearing cover

Motor flange bracket

Slinger collar

Discharge port

Gear side

Grease fitting

Gear Side Bearing Construction

Figure 8-7 Open Bearing Unit Construction

Anti-Load Side Bearing Unit Construction